14. Fill the cooling system with new coolant. See

Table 1 for the vehicle’s coolant capacity. Certain

equipment such as fuel heaters, water filters and

auxiliary heaters may increase the coolant ca-

pacity and require additional coolant. The cooling

system is filled when the coolant level reaches

the MAX line on the surge tank. Freightliner rec-

ommends the use of a precharged and premixed

antifreeze when refilling the cooling system. See

Table 2 for a list of some of the precharged anti-

freeze available. Use of an equivalent antifreeze

to those listed in the table is also acceptable.

Always check that the antifreeze used meets

Freightliner’s specifications and is at the proper

concentration for protection in the vehicle operat-

ing area. See Table 3 for antifreeze protection

information. Freightliner specifies that the anti-

freeze must be an ethylene glycol solution that

meets GM 6038 M Engineering Standards or a

ethylene glycol solution that has less than 0.1%

anhydrous sodium metasilicate, and meets either

GM 1825 M or GM 1899 M Engineering Stan-

dards. If supplemental coolant additives are

being used, add the supplements to the coolant

as necessary. See the coolant additive manufac-

turer’s instructions for the correct amount of addi-

tive required. Don’t forget to consider the volume

of the supplemental coolant additive being added

to the system when determining the amount of

coolant required to refill the system.

NOTE: You can mix purple-pink coolant (pre-

charged with a borate/nitrate-based additive)

with the common green coolant, although some

color change will be apparent.

15. Replace the surge tank cap(s).

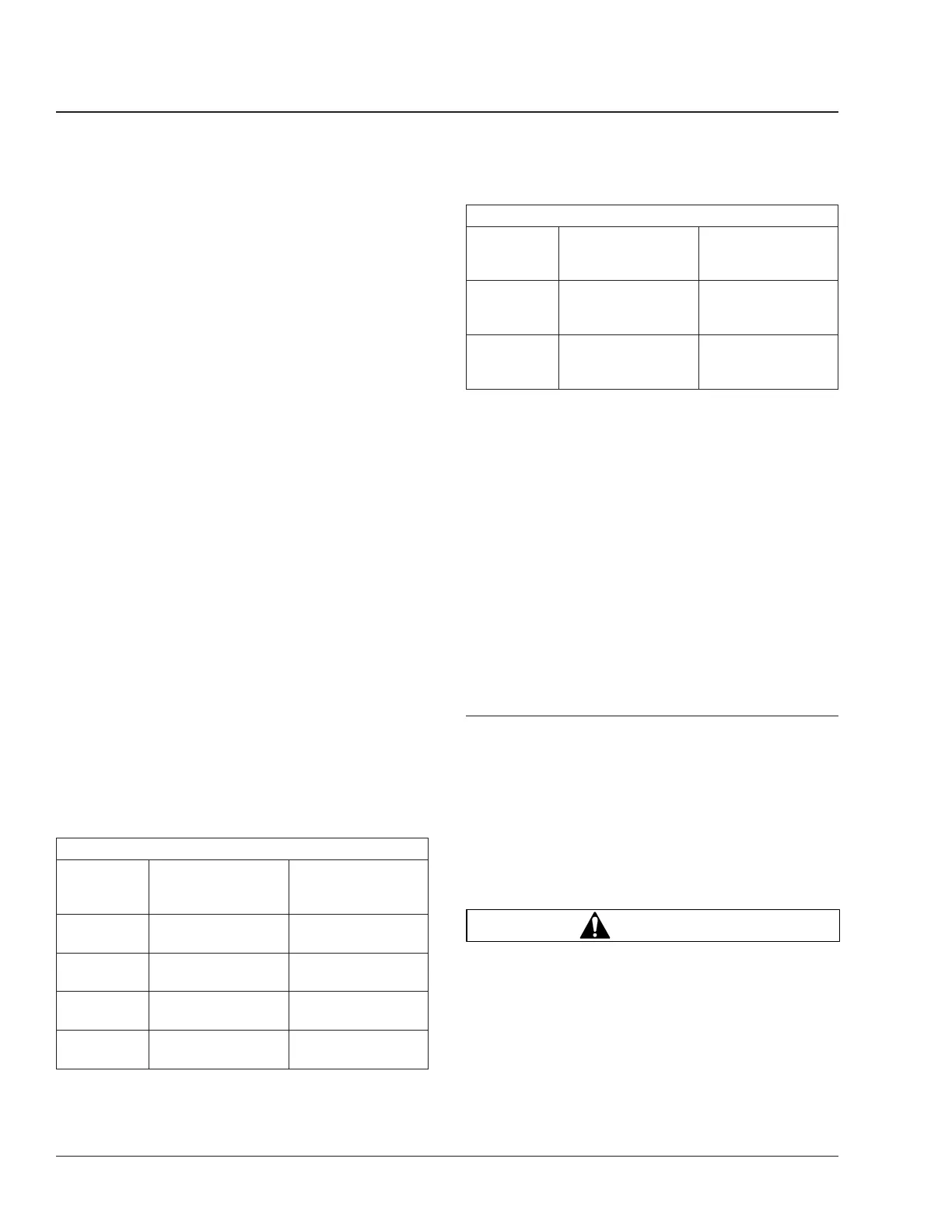

Engine Coolant Capacity (pre-EPA07 engines)

Engine

Capacity with 1000

sq. inch Radiator:

qt (L)

Capacity with 1200

sq. inch Radiator:

qt (L)

Caterpillar

C10 (3176)

39.5 (37.4) 40.6 (38.5)

Caterpillar

3406

53.2 (50.4) 54.1 (51.5)

Cummins

M11

39.0 (37.0) 40.2 (38.1)

Cummins

N14

51.1 (48.4) 52.3 (49.5)

Engine Coolant Capacity (pre-EPA07 engines)

Engine

Capacity with 1000

sq. inch Radiator:

qt (L)

Capacity with 1200

sq. inch Radiator:

qt (L)

Detroit

Diesel Series

55

43.0 (40.7) 44.1 (41.8)

Detroit

Diesel Series

60

54.8 (51.9) 56.0 (53.0)

Table 1, Engine Coolant Capacity (pre-EPA07

engines)

16. Return the hood or cab to the operating position.

See Group 60 of the

Century Class Trucks

Workshop Manual

for cab tilt instructions.

17. Start the engine and turn on the cab heater.

Allow the engine to warm up to normal operating

temperature. Check the radiator and hoses for

leaks. Repair if necessary.

18. Shut off the engine, then check the coolant level

in the surge tank. Add coolant if the level is not

between the MIN and MAX lines on the surge

tank.

20–03 Fan Clutch Check (Noise

Emission Control)

Horton Advantage

®

Fan Clutch

NOTE: If any part of the fan clutch needs to be

repaired or replaced, after performing the

checks below, see Group 20 of the

Century

Class Trucks Workshop Manual

.

1. Disconnect the electrical cables from the battery.

Drain all air from the air system. If equipped with

an air starter, drain the air starter reservoir.

WARNING

If the engine starts during this procedure, the fan

could cause personal injury. If the vehicle is

equipped with an air starter, be sure that the air

starter reservoir is drained.

2. Inspect the electrical connections and wires to

the fan clutch solenoid. Secure the connection if

loose; replace wires and connectors if damaged.

Engine Cooling/Radiator20

Century Class Trucks Maintenance Manual, January 200720/4

Loading...

Loading...