8. Install a new square-cut seal on each cover as-

sembly, and install the fluid filter elements on the

cover assemblies.

9. Install the filter and cover assemblies into the

filter compartment.

10. Align each cover assembly with the holes in the

channel plate sump, and push the cover assem-

blies in by hand to seat the seals.

CAUTION

Do not use the bolts to draw the filter covers to

the sump. This can damage the covers, seals, or

sump.

11. Install six bolts in each cover, and torque the

bolts 38 to 44 lbf·ft (51 to 61 N·m).

12. Replace the drain plug O-ring, and install the

drain plug. Tighten the drain plug 18 to 24 lbf·ft

(25 to 32 N·m).

13. Refill the transmission with fresh automatic trans-

mission fluid and check the fluid level. See

Table 4 for transmission lubricant capacities, and

Table 5 for approved transmission lubricants.

Allison Transmission Lubricant Capacities

Transmission Model Refill Capacity

*

:qt(L)

HD4060/4560 (standard sump) 36 (34)

†

HD4060/4560 (shallow sump) 26 (25)

†

*

Quantities listed are approximate. Add listed amount of fluid, then perform

a "hot check" and add fluid as needed. Do not overfill.

†

Add 3 quarts (3 liters) if equipped with a PTO.

Table 4, Allison Transmission Lubricant Capacities

Approved Automatic Transmission Lubricants

Lubricant Type

*

Temperature: °F (°C)

All Allison Models

Castrol TranSynd (synthetic) Above –22 (–30)

Dexron

®

III Above –17 (–27)

*

Lubricants listed in order of preference. Do not mix fluid types.

Table 5, Approved Automatic Transmission

Lubricants

26–03 Manual Transmission Air

Filter/Regulator Check,

Cleaning, or

Replacement

Eaton Fuller

1. Apply the parking brakes and chock the rear

tires. Drain the air reservoirs.

WARNING

Drain the air supply; if the air supply is not

drained before the air filter/regulator is serviced,

serious injury and component damage could re-

sult.

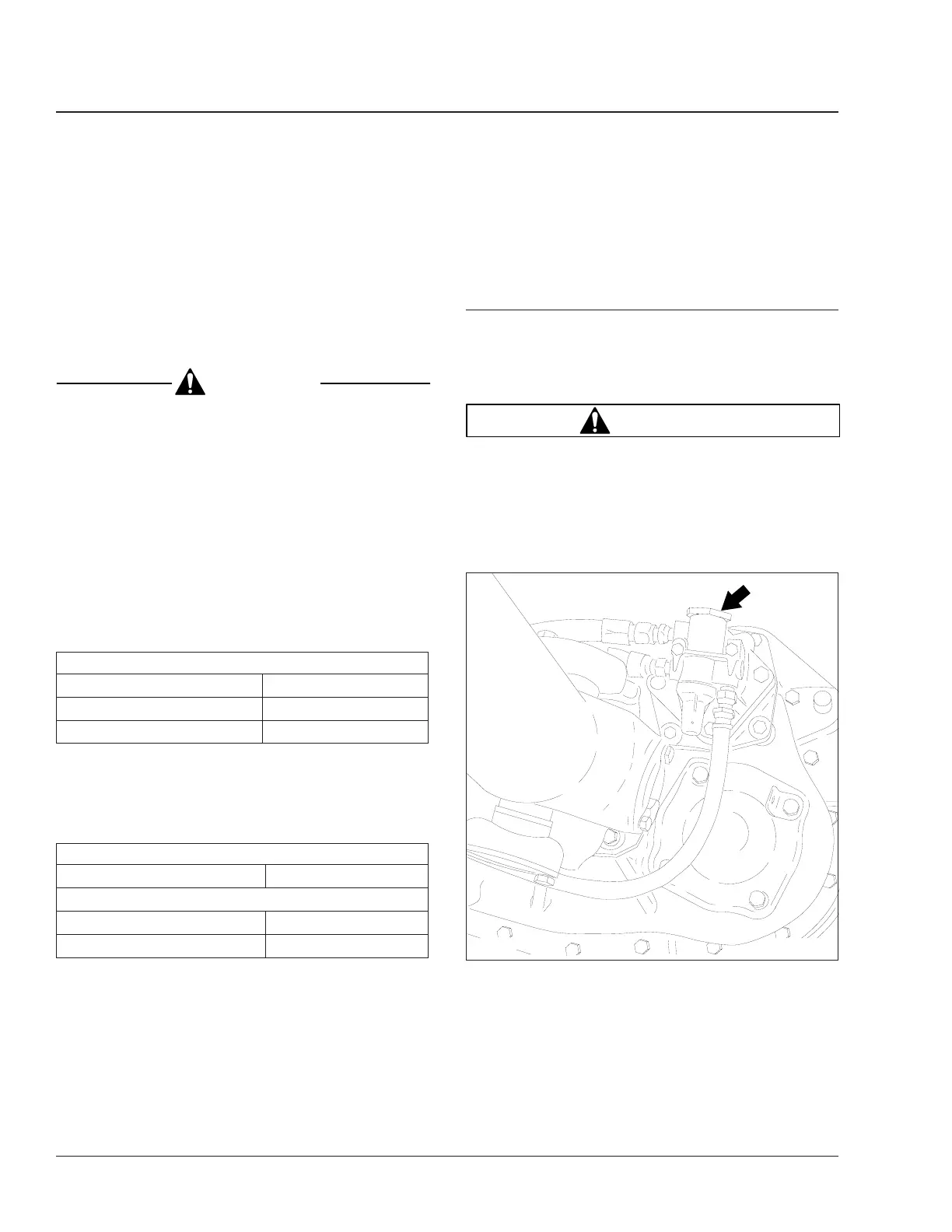

2. Clean the outside of the air filter/regulator with

cleaning solvent. See Fig. 3.

3. Remove the end cap, large O-ring, and filter ele-

ment from the filter housing. See Fig. 4. Remove

the small O-ring from the end cap.

f260037a

05/27/93

Fig. 3, Air Filter/Regulator (Eaton Fuller transmission

shown)

Transmission26

Century Class Trucks Maintenance Manual, April 200526/4

Loading...

Loading...