ter in the hydraulic system may cause undue wear of

transmission parts, make valves stick, and clog pas-

sages.

It is important to check the fluid level cold to deter-

mine if the transmission has a sufficient amount of

fluid to be safely operated until a hot check can be

performed.

1. Park the vehicle on a flat, level surface.

2. Apply the parking brakes and chock the rear

tires.

3. Run the engine for at least one minute.

4. Shift from DRIVE to NEUTRAL, and then shift to

REVERSE to fill the hydraulic system.

5. Shift to NEUTRAL and allow the engine to idle at

500 to 800 rpm.

6. With the engine running at idle, remove the dip-

stick from the tube and wipe it clean.

7. Insert the dipstick into the tube and remove the

dipstick.

8. Check the fluid level reading and repeat the

check procedure to verify the reading.

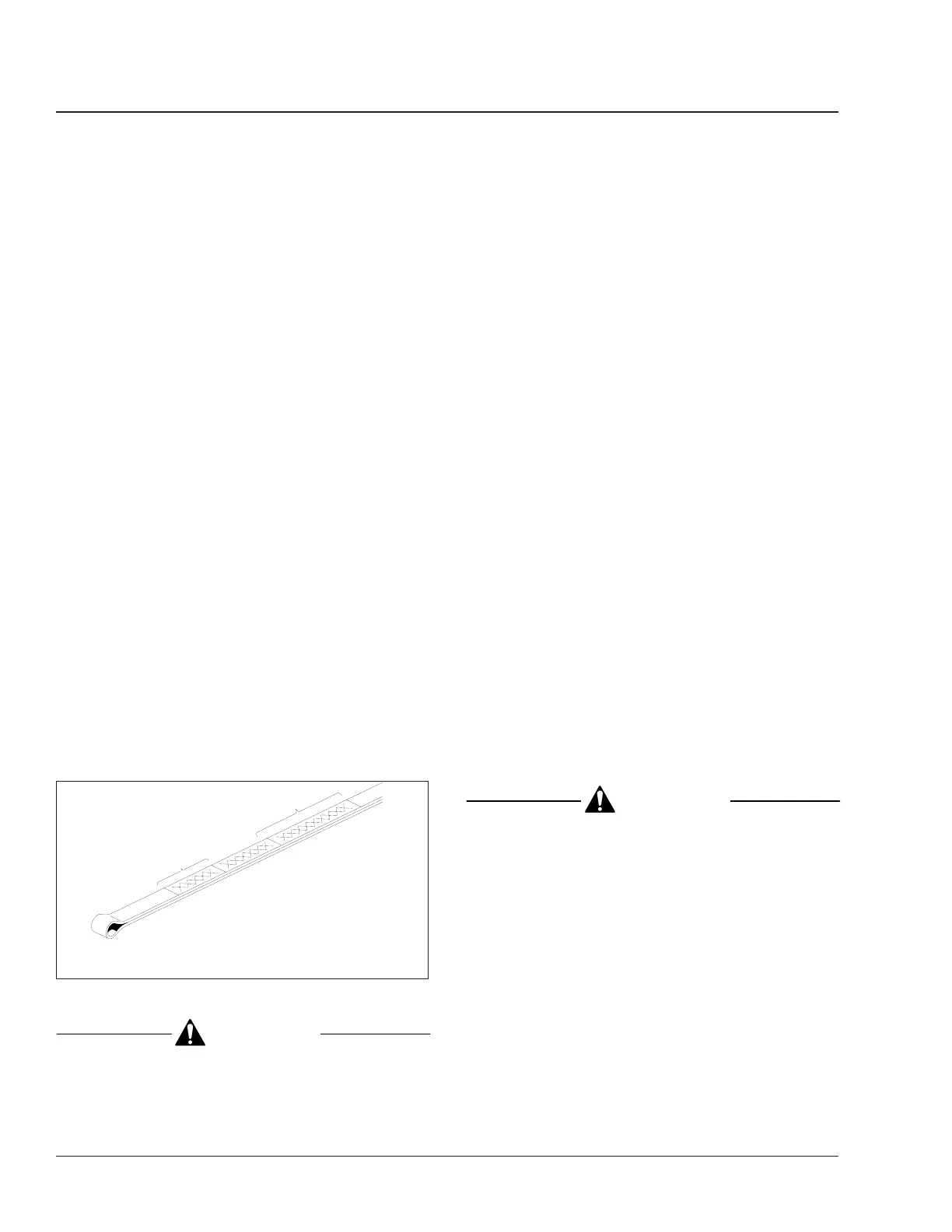

If the fluid level is within the COLD RUN band,

the transmission may be operated until the fluid

is hot enough to perform a hot check.

If the fluid level is not within the COLD RUN

band, add or drain fluid as needed to adjust the

fluid level to the middle of the COLD RUN band.

See Fig. 5.

CAUTION

As the fluid temperature increases, so does the

fluid level. Do not fill above the COLD RUN band if

the transmission fluid is below normal operating

temperature.

NOTE: Perform a hot check at the first opportu-

nity after the normal operating temperature, 160

to 200°F (71 to 93°C), has been reached.

Hot Check

1. Park the vehicle on a flat, level surface. Apply

the parking brakes and chock the rear tires.

2. Shift the transmission to NEUTRAL.

3. Operate the engine at idle (500 to 800 rpm) until

normal operating temperature is reached. Check

that the sump temperature is 160 to 200°F (71 to

93°C). Check that the converter-out temperature

is 180 to 220°F (82 to 104°C).

4. With the engine idling, remove the dipstick from

the tube and wipe it clean.

5. Insert the dipstick into the tube and remove the

dipstick.

6. Check the fluid level reading and repeat the

check procedure to verify the reading. Safe oper-

ating level is within the HOT RUN band on the

dipstick. The HOT RUN band is between the

HOT FULL and HOT ADD marks.

If the fluid level is not within the HOT RUN band,

add or drain fluid as needed to bring the fluid

level within the HOT RUN band. See Fig. 5.

Eaton Fuller and Meritor

CAUTION

Operating a transmission with the fluid level

higher or lower than recommended can result in

transmission damage. Do not overfill the transmis-

sion. Overfilling will force fluid out of the case

through the main shaft openings. Fluid overflow

may also drain onto the clutch or clutch brake,

causing additional problems.

Do not mix types and brands of fluid, because of

possible incompatibility. Do not use fluid addi-

tives, friction modifiers, extreme-pressure gear

fluids, or multiviscosity lubricants.

With the transmission at operating temperature, and

the vehicle on a level surface, check the fluid level in

the transmission.

12/01/97

A

B

f270002a

A. Cold Run Band B. Hot Run Band

Fig. 5, Dipstick Markings

Transmission26

Century Class Trucks Maintenance Manual, April 200526/6

Loading...

Loading...