33–01 Knuckle Pin Lubrication,

Meritor Axles

CAUTION

Use regulated pressure when lubricating the

knuckle assemblies, otherwise damage could re-

sult to the knuckle caps.

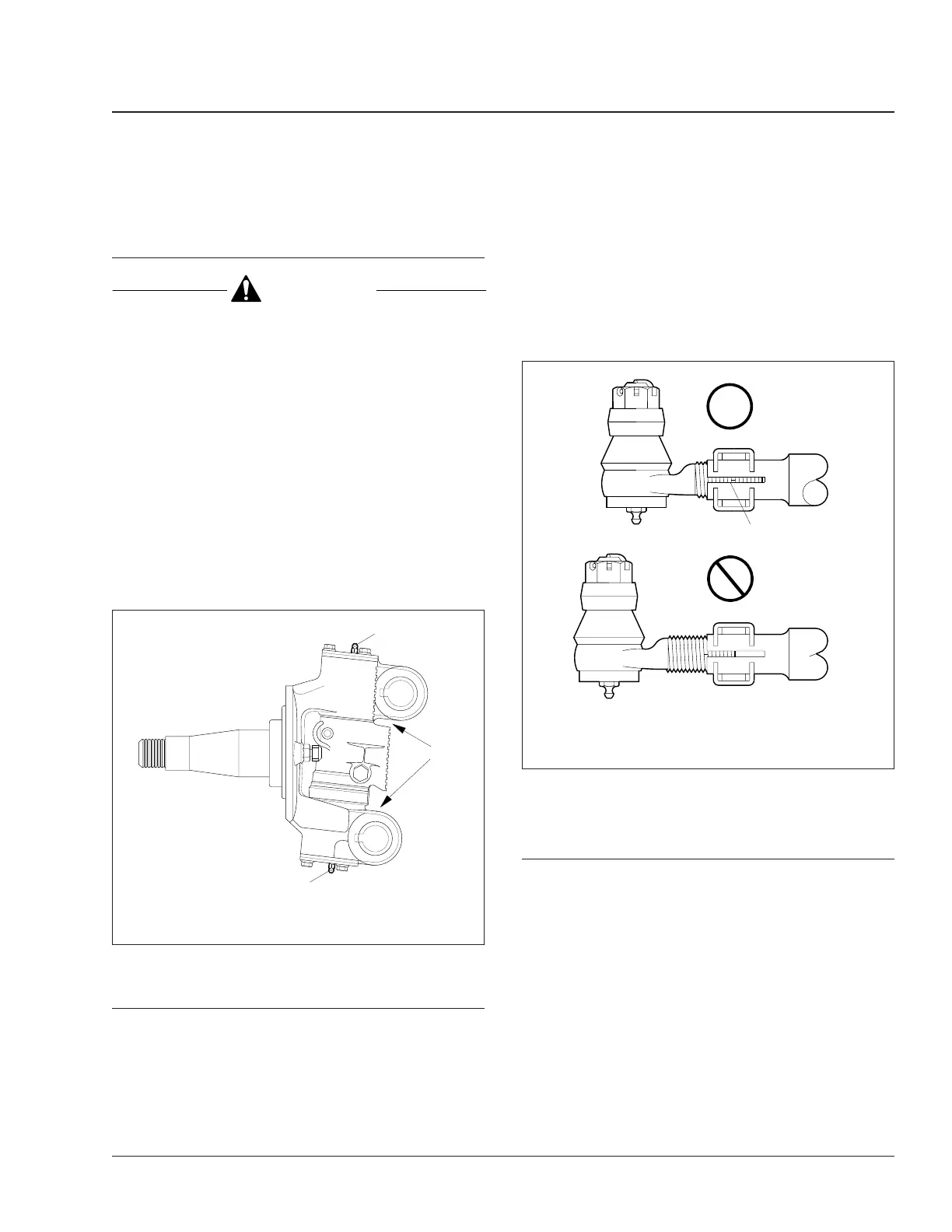

When lubricating knuckle pin bushings, do not raise

the front axle. Wipe the lube fittings clean, and apply

multipurpose chassis grease, NLGI Grade 1 (6% 12-

hydroxy lithium stearate grease) or NLGI Grade 2

(8% 12-hydroxy lithium stearate grease) until new

grease is seen at the bushing grease seal opposite

the fittings. The grease seal will accept grease pres-

sure without damage, and is designed to have

grease pumped out through it during lubrication.

Even if grease leaks out around the top, or bottom-

plate gasket, continue pumping until new grease is

seen at the bushing seal opposite the grease fitting.

See Fig. 1.

33–02 Tie Rod Inspection

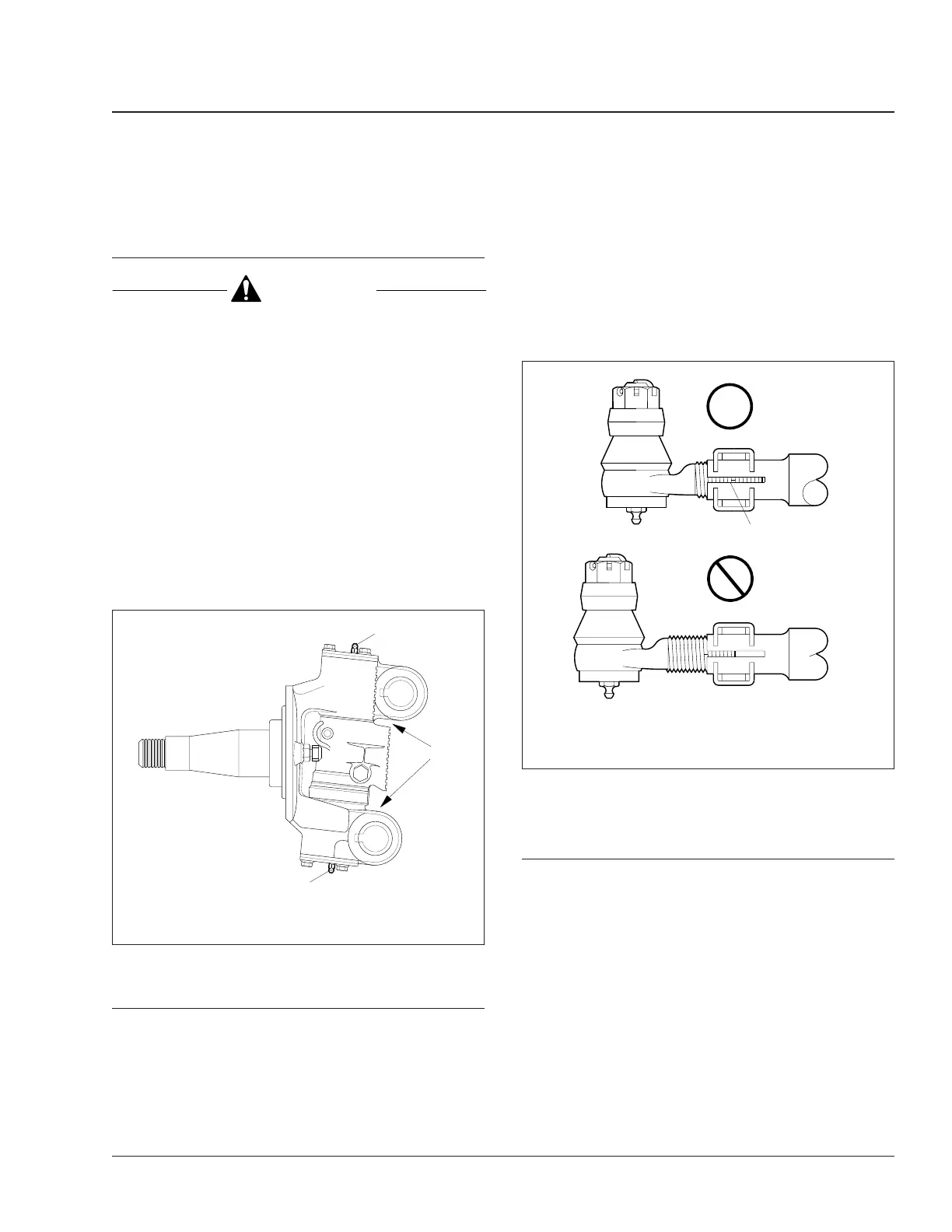

Inspect the tie-rod ends as follows:

1. Shake the cross-tube. A loose fit, or movement

between the tapered shaft of the ball and the

cross-tube socket members indicates that the

tie-rod end assembly must be replaced.

2. The threaded portion of the tie-rod end assembly

must be inserted all the way into the cross-tube

split for adequate clamping. See Fig. 2. Replace

the components if this cannot be done. For in-

structions, see Group 33 of the

Century Class

Trucks Workshop Manual

.

33–03 Tie Rod Lubrication,

Meritor Axles

For any Meritor axle that requires lubrication of the

tie-rod ends, wipe the grease fittings clean, then

pump multipurpose chassis grease, NLGI Grade 1

(6% 12-hydroxy lithium stearate grease) or NLGI

Grade 2 (8% 12-hydroxy lithium stearate grease),

into the tie-rod ends until all used grease is forced

out and fresh grease is seen at the ball stud neck.

09/06/96 f320032a

A

1

1

A. Grease Exit

1. Grease Fitting

Fig. 1, Meritor Knuckle Pin Lubrication

f320033a

1

OK

OK

02/27/2007

NOTE: Shown without pinch bolt to provide clarity.

1. Cross-Tube Split

Fig. 2, Tie-Rod End Adjustment

Front Axle 33

Century Class Trucks Maintenance Manual, July 2003 33/1

Loading...

Loading...