cause permanent damage to unprotected eyes. Do

not point the air stream in the direction of other

persons.

5.2 Wash the strainer in solvent, and blow it

dry with compressed air to remove oil and

metal particles.

5.3 Install and tighten the magnetic strainer

40 to 60 lbf·ft (54 to 81 N·m).

6. Clean the fill plugs and drain plugs. To help

clean magnetic plugs, a piece of key stock or

any other convenient steel slug may be used to

short the two magnetic poles and divert the mag-

netic field.

IMPORTANT: Magnets will rapidly lose effective-

ness as collected material bridges the gap be-

tween the two poles. Clean or change the plugs

before this occurs. It may be necessary to clean

or change the plugs one or more times between

lubrication change intervals.

7. After cleaning, install and tighten the drain

plug(s) 40 to 60 lbf·ft (54 to 81 N·m).

8. Fill the axle with recommended lubricant. See

Table 1 for recommended drive axle lubricants,

and Table 2 for drive axle lubricant capacities.

Dana Spicer Drive Axle Recommended Lubricant

Lubricant Type Condition

Lubricant SAE

Viscosity

Grade

Dana Spicer

Roadranger

®

Synthetic Drive Axle

Lubricants, or

Equivalent with

Military Specification

MIL–L–2105D

Over-the-Road

Service

75W–90

Off-Highway

Equipment, or

Under Extra

Heavy Loads

80W–140

Table 1, Dana Spicer Drive Axle Recommended

Lubricant

NOTE: Some Dana Spicer axles have a

small tapped and plugged hole near and

below the housing oil fill hole. This smaller

hole is for a lubricant temperature indicator

only, and should not be used as a fill or level

hole.

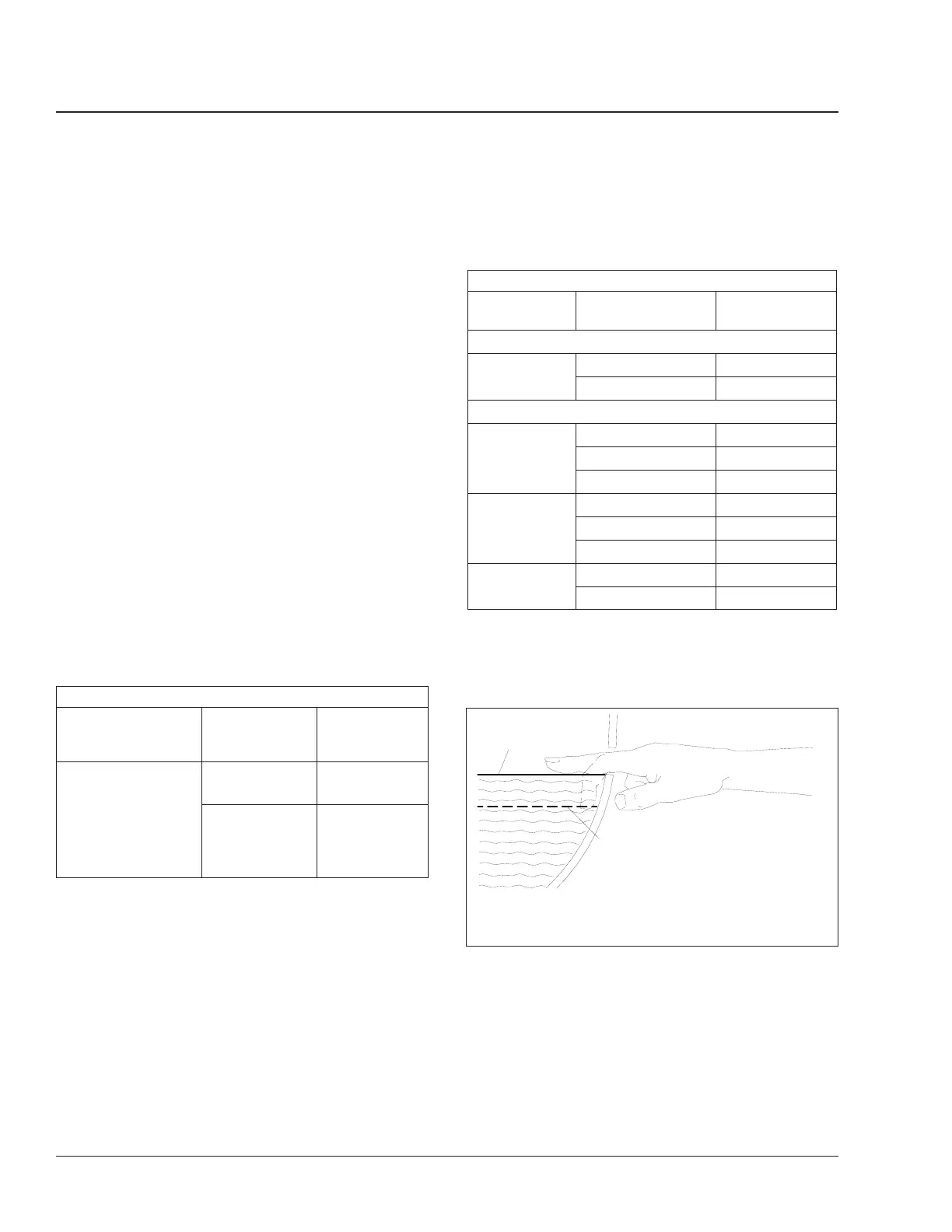

8.1 Using recommended lubricant, fill the axle

through the oil fill hole or standpipe open-

ing. Lubricant should be level with the

bottom of the oil fill hole (see Fig. 3)or

top of the standpipe opening.

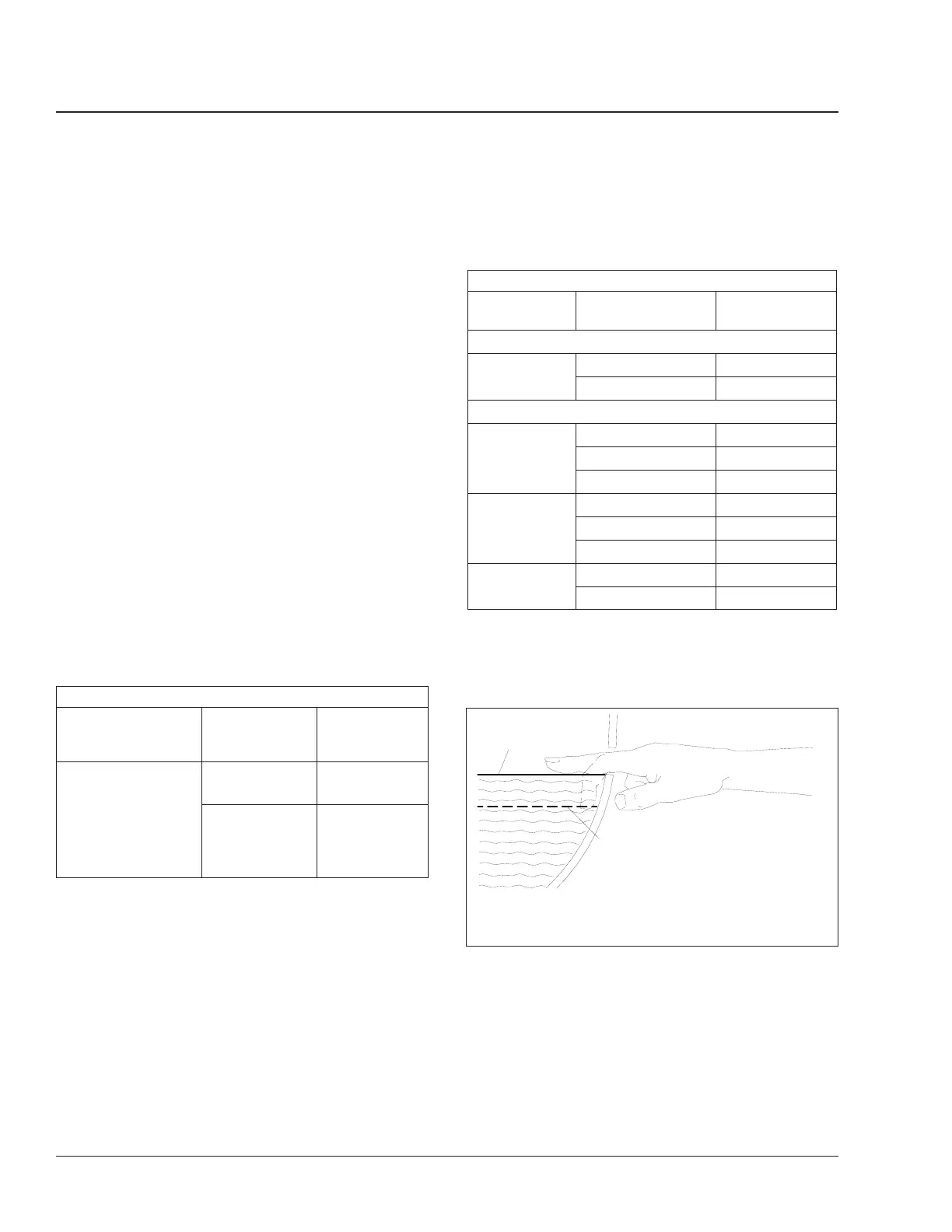

Dana Spicer Drive Axle Lubricant Capacities

Axle Type Axle Model

Capacity

*

:

pints (liters)

Single-Drive Axle Installation

Single

Reduction

23080S, 23080D 40 (18.9)

23105S, 23105D 48 (22.7)

Dual-Drive Axle Installation

Single

Reduction

DD404, DD404–P 31 (14.7)

†

DS404, DS404–P 39 (18.5)

†

DS461–P 43 (20.3)

†

Dual Range

(2-Speed)

DT402, 402–P 34 (16.1)

†

DT451–P 39 (18.5)

†

DT461–P 43 (20.3)

†

Double

Reduction

DP451–P 34 (16.1)

†

DP461–P 43 (20.3)

†

*

Quantities listed are approximate. Fill axle until lubricant is level with bot-

tom of fill hole with vehicle on level ground.

†

Add 2 pints (1 L) of additional lubricant to the power divider.

Table 2, Dana Spicer Drive Axle Lubricant Capacities

8.2 Install and tighten the fill plug 40 to 60

lbf·ft (54 to 81 N·m).

8.3 For forward drive axles, remove the

power divider fill plug, located slightly off-

set to the right in the top portion of the

forward differential carrier. See Fig. 4.

f350061a

A

B

06/07/94

A. Correct (lube level at bottom of fill hole)

B. Incorrect (lube level below fill hole)

Fig. 3, Axle Lubricant Level Inspection

Rear Axle35

Century Class Trucks Maintenance Manual, April 200535/2

Loading...

Loading...