41–01 Driveline Inspecting

Inspecting

1. Check that the yoke-strap capscrews (Fig. 1,

Ref. 4) are tightened as follows:

• Spicer 1590 and 1610: 50 to 60 lbf·ft (68

to 81 N·m)

• Spicer 1710: 125 to 135 lbf·ft (170 to 183

N·m)

CAUTION

Do not overtighten the yoke-strap capscrews, due

to the extreme load occurring at high-speed rota-

tion. A loose or broken capscrew at any point in

the driveline weakens the driveline connection,

which could eventually result in serious vehicle

damage.

2. Check each of the output and input end yokes

(Fig. 1, Refs. 2 and 11) for cracks and loose-

ness. Replace cracked yokes. If any end yoke

can be moved in or out on its shaft, or can be

rocked on its shaft, disconnect the driveshaft and

U-joint from the end yoke. Check the drive com-

ponent’s shaft seal for leakage or other visible

damage that may have been caused by the

loose yoke. Replace the seal if needed. Tighten

the end-yoke nut to the value in Table 1.Ifthe

end yoke is still loose after tightening the yoke

nut, install a new yoke and yoke nut.

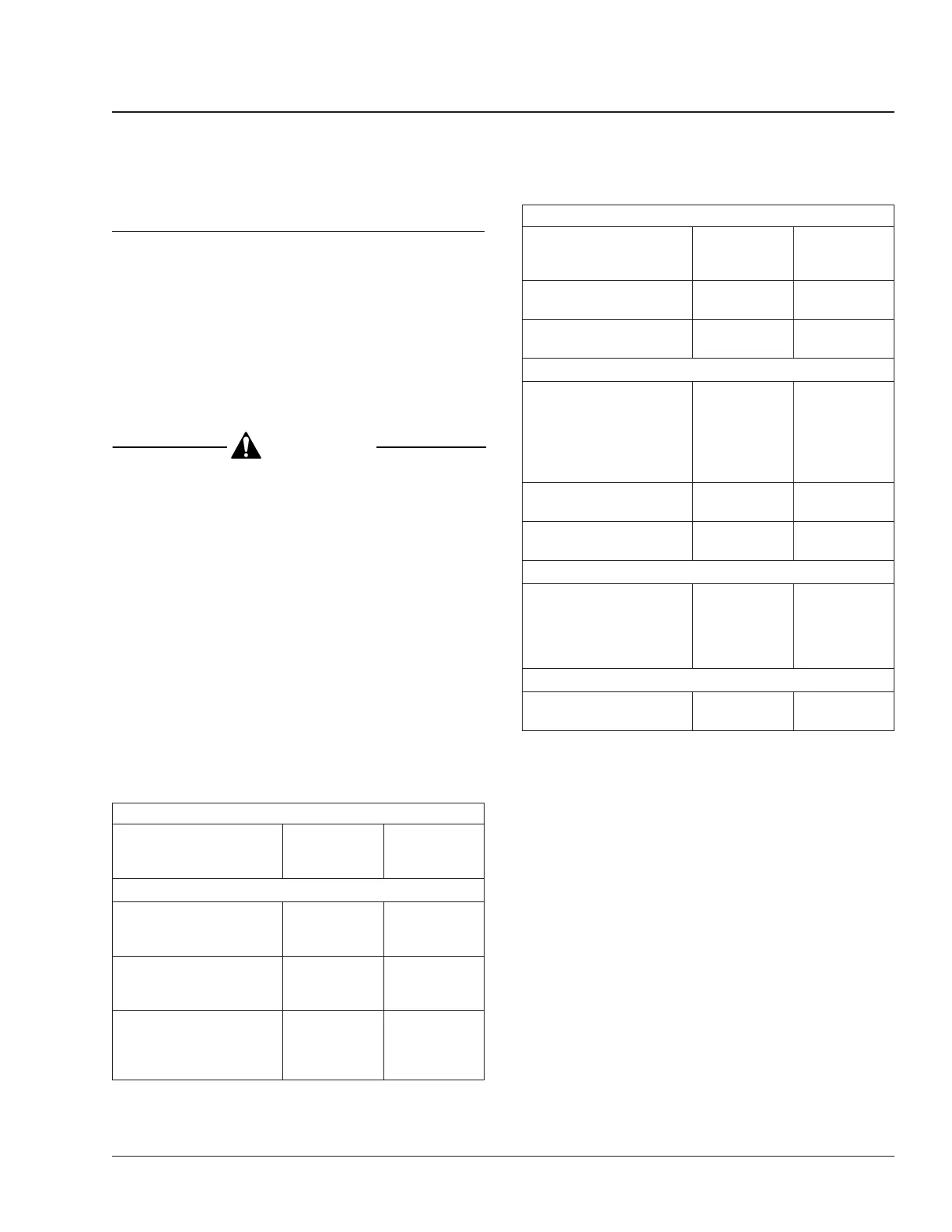

End-Yoke Nut Torque Specifications

Description

Thread

Size

Torque

lbf·ft

(N·m)

Transmissions

Fuller FS 4005,

5005, 5106,

6105, and 6206

1-1/4–18

300–350

(405–475)

Fuller RT 6609,

RT/RTO 6610, and

RT 8609

1-1/2–18

400–450

(540–610)

Fuller T 8607,

RT 7608LL,

RT 8608L, and

RT/RTO 6613

2–16

450–500

(610–675)

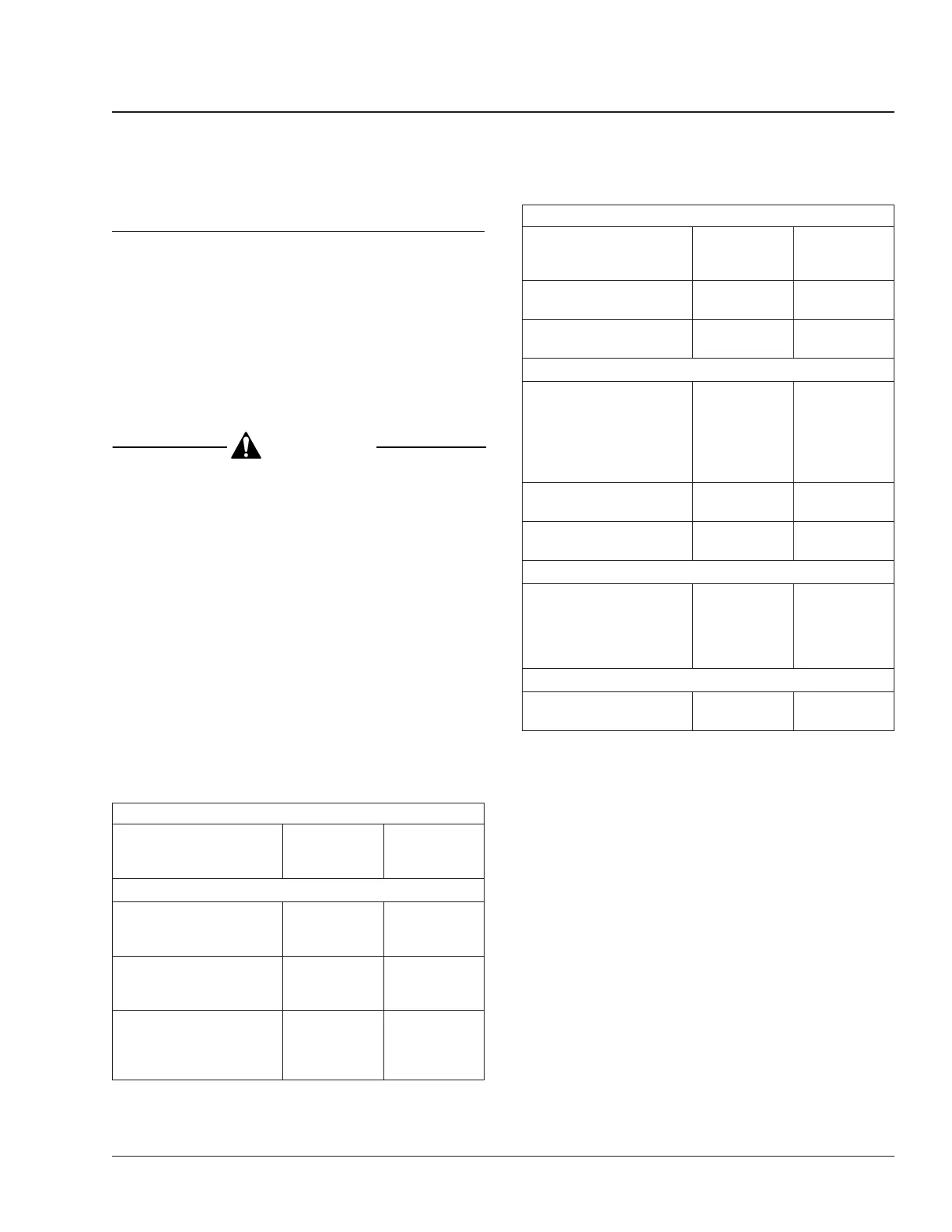

End-Yoke Nut Torque Specifications

Description

Thread

Size

Torque

lbf·ft

(N·m)

Allison AT-545 1/2–20

*

100–120

(140–160)

Allison MD Series 2–16

600–800

(815–1085)

Single Axle Input Shaft

Meritor RS–13–120,

RS–15–120 and –210,

RS–17–140 and –20,

RS–19–145 and –220,

and

RS–21–145 and –230

M32 x 1.5

740–920

(1000–1250)

Meritor RS–23–160 M45 x 1.5

1000–1230

(1355–1670)

Meritor RS–23–240 M39 x 1.5

920–1130

(1250–1530)

Tandem Axle Input and Output Shafts

Meritor

RD– and RR–17–145,

(of RT–34–145), and

RD– and RR–20–145

(of RT–40–145)

M39 x 1.5

920–1130

(1250–1530)

Coupling Shaft (Midship Bearings)

Spicer 1590, 1610,

and 1710

1-1/4–18

475–525

(644–712)

*

The Allison AT-545 transmission output shaft end-yoke is retained by a

1/2-20 x 1-1/2-inch bolt and a 1-1/16-inch washer. Both the bolt and the

washer must be replaced each time they are removed.

Table 1, End-Yoke Nut Torque Specifications

NOTE: If the end-yoke locknut was removed for

any reason, install a new one.

3. Check the U-joint assemblies for wear by at-

tempting to move the driveshaft up and down,

and from side to side. If movement of the U-joint

trunnion in the bearings is greater than 0.006

inch (0.15 mm), replace the U-joint assembly.

4. Check the midship bearing and bracket for loose-

ness and deterioration by attempting to move the

driveshaft up and down, and from side to side. If

the bearing is loose on its shaft, or rattles, re-

place it. If the bearing bracket is loose on the

frame, or the bearing mount is loose on the

bracket, tighten the mounting bolt nuts 91 lbf·ft

Driveline 41

Business Class Trucks Maintenance Manual, January 1998 41/1

Loading...

Loading...