(123 N·m). Replace the midship bearing assem-

bly if the rubber cushion is worn or oil-soaked.

5. Check the slip-joints for spline wear by trying to

bend the sleeve-yoke and splined shaft back and

forth (Fig. 2). If looseness is greater than 0.007

inch (0.18 mm), replace both the sleeve-yoke

and the splined shaft.

6. Check the driveshaft tubes for dents, bends,

twists, or other damage. If any tube appears to

be damaged, remove the driveshaft and check

the runout on the tube. If the tube is not straight

(and cannot be straightened) within 0.015 inch

(0.38 mm) on the slip-joint seal surface of the

splined shaft, 0.020 inch (0.51 mm) on the tube

3 inches (76 mm) from the front and rear welds,

and 0.025 inch (0.635 mm) at the center of the

tube, replace the tube. See Fig. 3.

If the driveshaft tube requires straightening or

replacement, balance the repaired driveshaft be-

fore installing it. See Group 41 of the

Business

Class

®

Trucks Service Manual

.

7. Check the driveshaft for missing balance

weights, and for debris build-up. Remove any

build-up. If any balance weights are missing, re-

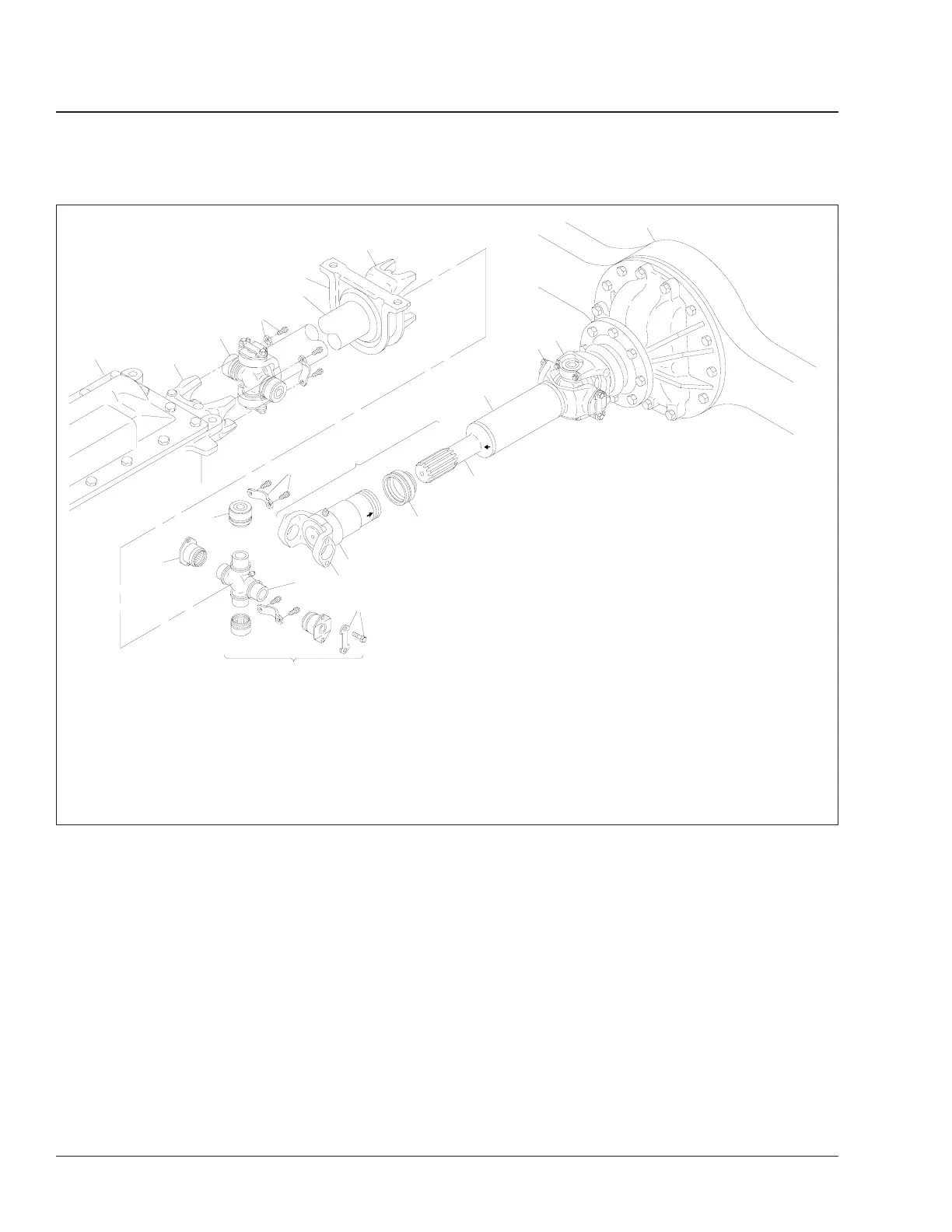

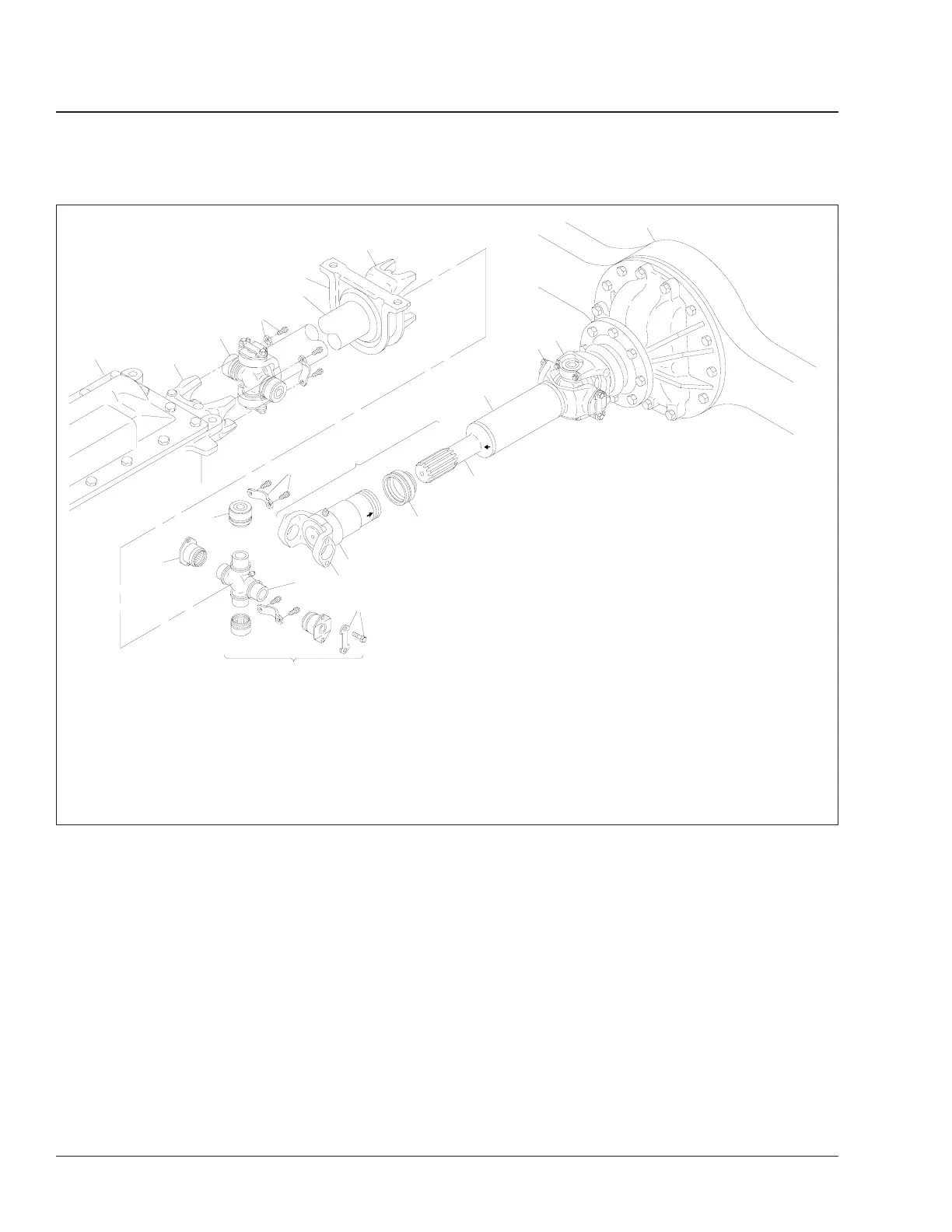

f410057a

10/06/94

1

2

3

5

6

4

2

4

7

16

15

14

13

18

17

9

8

3

7

10

11

12

NOTE: Not all fasteners are shown.

1. Transmission

2. Half-Round End Yoke

3. U-Joint Assembly

4. Yoke Strap and Capscrew

5. Coupling Shaft

6. Midship Bearing and Mount

7. Bearing Cup

8. Slip-Joint Assembly

9. Driveshaft Tube

10. Driveshaft Yoke

11. Input Shaft Half-Round End

Yoke

12. Rear Axle

13. Splined Shaft

14. Dust Seal

15. Sleeve Yoke

16. Full-Round-Yoke Lug

17. U-Joint Cross

18. Lockplate and Capscrew

Fig. 1, Driveline Assembly With Midship Bearing For Single-Axle Installation

Driveline41

Business Class Trucks Maintenance Manual, January 199841/2

Loading...

Loading...