move the driveshaft and have it balanced; see

Group 41 of the

Business Class

®

Trucks Service

Manual

.

8. For driveshafts with slip-joints, check that the

yoke plug is not loose or missing. See Fig. 4,

Ref. 2. Replace the yoke plug if needed. If the

yoke plug is missing, the splined shaft may be

hitting the yoke plug and knocking it out; check

the driveshaft for proper length.

41–02 Driveline Lubricating

U-Joint Lubricating

1. Wipe all old grease and dirt from each U-joint

grease fitting. See Fig. 4, Ref. 8.

2. Use a hand-type grease gun, or a high-pressure

gun with a low-pressure adapter, to lubricate the

U-joints.

NOTE: If a low-pressure adapter is not used

with the high-pressure gun, the U-joints may not

receive enough lubricant.

3. Using lithium 12 hydroxy stearate grease (NLGI

grade 1 or 2, with EP additives), lubricate until

new grease can be seen at all four U-joint seals.

IMPORTANT: Fresh lubricant must be seen es-

caping from

all four

bearing cup seals of each

U-joint.

On full-round yokes, if most of the grease being

added to a U-joint can be seen escaping from

just one of the U-joint seals, bend the tabs of

the lockstrap away from the heads of the bear-

f410012a

05/27/93

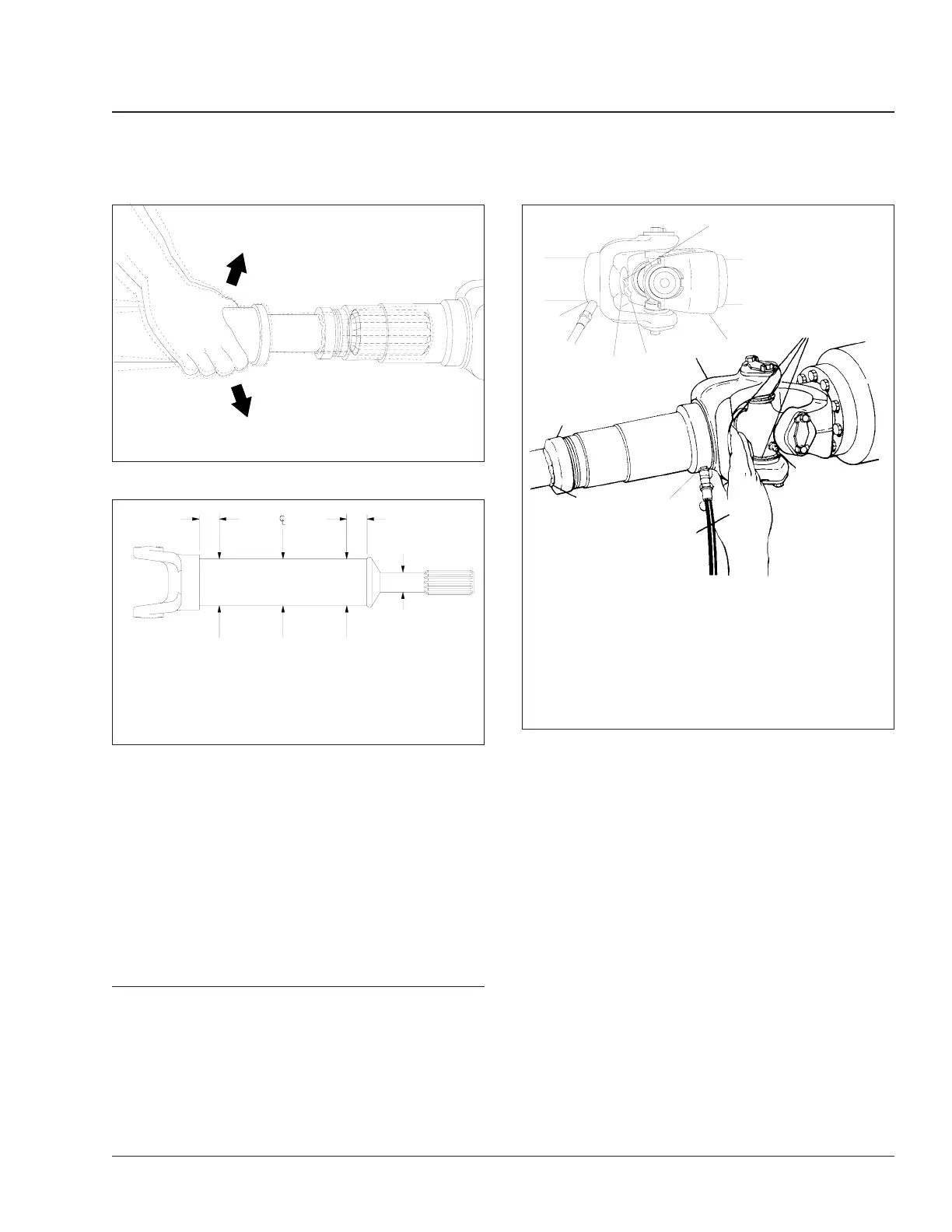

Attempt to bend the sleeve yoke and splined shaft back

and forth.

Fig. 2, Slip-Joint Spline Wear Checking

f410110b

06/13/96

A

A

B

C

C

D

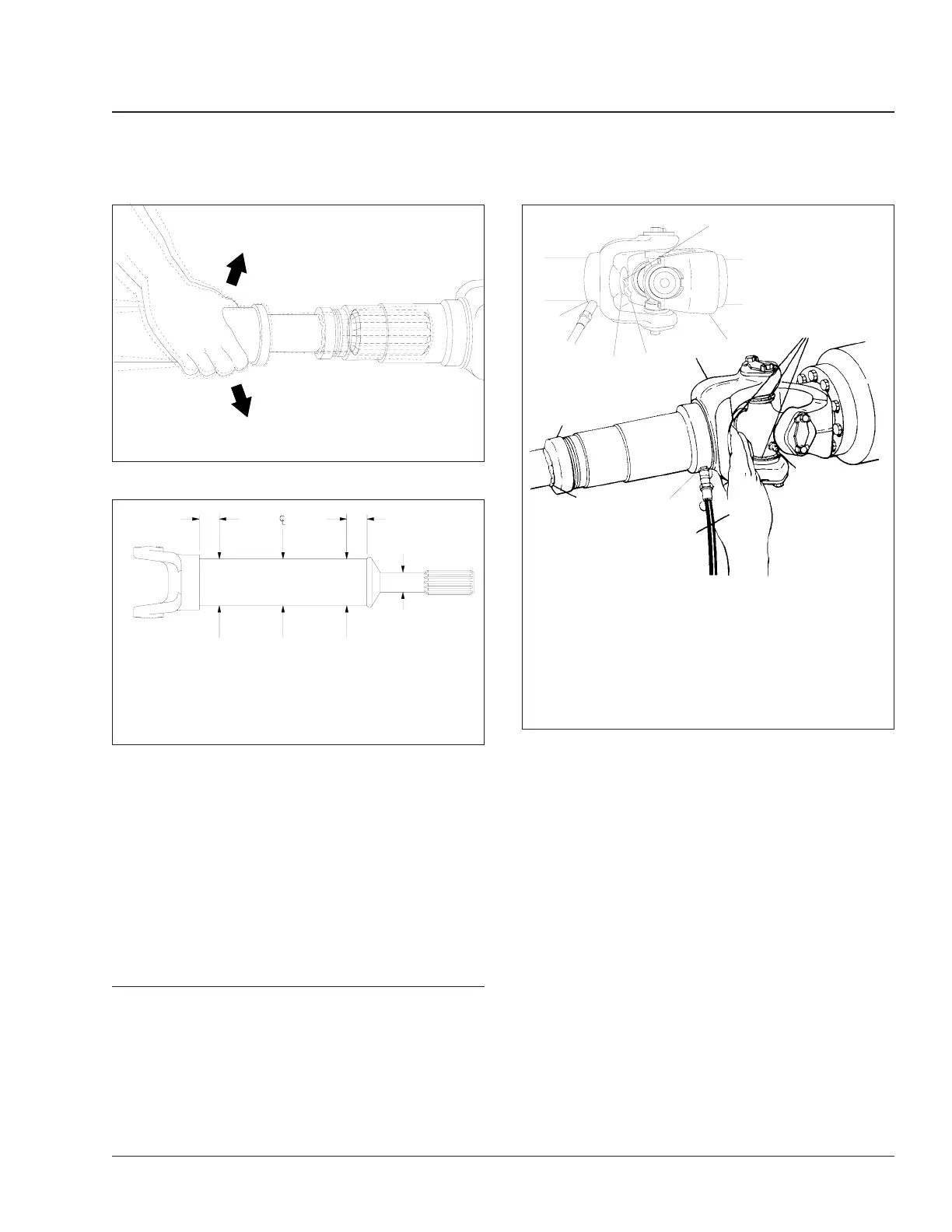

A. Measurement: 3" (76 mm)

B. Measurement: 0.015" (0.38 mm)

C. Measurement: 0.020" (0.51 mm)

D. Measurement: 0.025" (0.635 mm)

Fig. 3, Driveshaft Runout Specifications

f410050a

10/20/93

1

1

2

3

3

3

4

5

6

7

8

A

A. After grease appears, cover the pressure-relief hole

while continuing to lubricate.

1. Slip-Joint Grease

Fitting (with grease

gun attached)

2. Yoke Plug

3. Grease

4. Half-Round Yoke

5. Yoke Plug Pressure-

Relief Hole

6. Slip-Joint Seal

7. Full-Round Yoke

8. U-Joint Grease Fitting

Fig. 4, Slip-Joint and U-Joint Lubricating

Driveline 41

Business Class Trucks Maintenance Manual, January 1998 41/3

Loading...

Loading...