slack adjusters use a special NLGI Grade

synthetic polyurea grease and do not require

lubrication for 3 years or 500,000 miles (800

000 km), whichever comes first. The extended-

maintenance slack adjusters are lubricated

during the brake reline service interval. For

service and lubrication instructions, see Group

42 of the Business Class M2 Plus Workshop

Manual.

For slack adjusters with grease fittings and for

operating temperatures above –40°F (–40°C), use an

NLGI Grade 1 clay-base grease, or an NLGI Grade 1

or 2 lithium-base grease.

For slack adjusters with grease fittings and for

operating temperatures below –40°F (–40°C) and

above –65°F (–54°C), use an NLGI Grade 2

synthetic oil, clay-base grease.

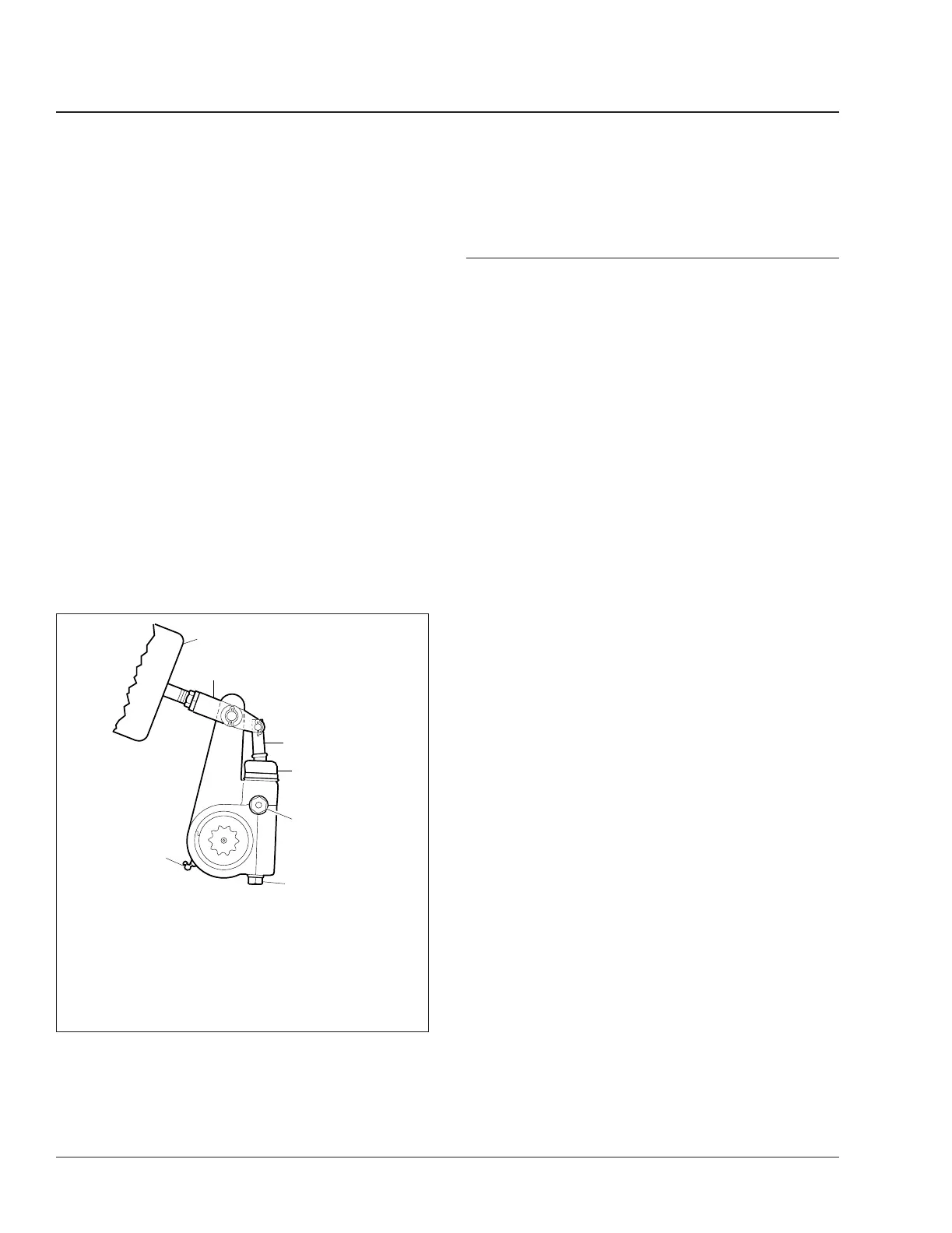

Lubricate the slack adjuster at the grease fitting until

grease is forced past the pressure-relief capscrew or

past the gear splines around the inboard snap ring.

See

Fig. 8.

42–08 Air Dryer AD–9, AD–IP,

AD–IS/DRM Check

IMPORTANT: Review the warranty policy before

performing any intrusive maintenance

procedures. An extended-warranty may be

voided if intrusive maintenance is performed

during this period.

Because no two vehicles operate under identical

conditions, maintenance and maintenance intervals

will vary. Experience is a valuable guide in

determining the best maintenance interval for any

one particular operation.

Every 900 operating hours, or 25,000 miles (40 225

km), or 3 months:

1. Check for moisture in the air brake system by

opening reservoir drain valves and checking for

the presence of water. If moisture is present, the

desiccant cartridge may require replacement;

however, the following conditions can also cause

water accumulation and should be considered

before replacing the desiccant:

1.1 An outside air source has been used to

charge the system. This air did not pass

through the drying bed.

1.2 Air usage is exceptionally high and not

normal. This may be due to high air

system leakage.

1.3 In areas where more than a 30-degree

range of temperature occurs in one day,

small amounts of water can temporarily

accumulate in the air brake system due to

condensation. Under these conditions, the

presence of small amounts of moisture is

normal.

NOTE: A small amount of oil in the system is

normal and should not be considered as a

reason to replace the desiccant cartridge. Some

oil at the dryer exhaust is normal.

2. Visually check for physical damage such as

chaffed or broken air and electrical lines and

broken or missing parts.

3. Check mounting bolts for tightness. Tighten to 30

to 35 lbf·ft (41 to 47 N·m).

4. Perform the operational and leakage tests listed

below.

f420012a

10/20/93

1

2

3

4

5

6

7

1. Brake Chamber

2. Clevis

3. Actuator Rod

4. Boot

5. Pressure-Relief Capscrew, Gasket, Pawl Spring,

and Pawl

6. Manual Adjusting Nut

7. Grease Fitting (or plug)

Fig. 8, Meritor Automatic Slack Adjuster

Brakes42

Business Class M2 Plus Maintenance Manual, 02/10/202342/8

Loading...

Loading...