610.020-IOM (NOV 19)

Page 6

EVAPORATOR AND AIR COOLER

INSTALLATION - OPERATION - MAINTENANCE

Operation

PRE START-UP

• Check all electrical and refrigerant connections.

• Ensure unit voltage as indicated on the nameplate

matches supply voltage.

• Conrm that the air cooler is wired in accordance with

all applicable local and national standards.

• Ensure the unit is securely mounted and fastened at the

hanger points and the unit is level.

• Conrm all fasteners for fans and motors are tight.

• Ensure that all service valves for liquid supply, suction,

and hot gas feed lines are open.

• Conrm proper drainage of condensate from the drain

pan.

• Check operation of condensate drain heaters.

START-UP

• Check all screwed connections, especially at moveable

parts.

• Check tube connections. Make sure that brackets are in

place and connection screws are secured.

• Check electrical connections of motors, heater ele-

ments, and any additional components, if applicable.

• Run the fans and check the direction of rotation. Make

sure that there is no transport damage.

• Properly purge the system of all air, evacuating Freon

and ammonia units.

• During the test run, observe the equipment and check

the following:

- Silent operation of the fans (bearings, contacts, bal-

ance)

- Power requirements of electrical motors

- Leakages

- For direct expansion applications, check superheat

- After 48 hours of operation, recheck the equipment,

specically all rotating parts.

POST START-UP

• Conrm the correct rotation of all impellers.

• High moisture load in new rooms can lead to rapid frost

accumulation on the nned surface. It may be necessary

to initiate a manual defrost.

• Conrm that the air unit has the correct refrigerant

charge.

• Pull down after start up may result in higher than normal

suction pressure, which could cause nuisance tripping of

compressor overloads.

• Check drain pan for proper drainage.

• Check thermostatic expansion valves for proper super-

heat settings.

• Adjust all adjustable controls and valves in the eld to

meet required operating conditions.

Electrical wiring

FIELD WIRING

WARNING

All wiring must be undertaken by qualied personnel

in accordance with national and local electrical codes

and standards.

NOTICE

All wiring must be in accordance with all local and

national codes.

NOTICE

Refer to the submittal documentation and unit name-

plate for voltage information.

NOTICE

Electrical drawings indicate "nameplate" amps. Oper-

ating motor amps can be found on submittal drawing.

Before wiring the equipment, conrm that the electrical

supply is in accordance with the electrical information on

the unit nameplate and unit wiring schematics shipped with

the unit. All electrical components such as circuit breakers,

branch circuit protection, contactors, overload relays, and

wire sizing must be in accordance with national and local

electrical codes and standards. The wiring schematics

shipped with the unit provide the design motor amps and

protection ratings required for branch circuit protection,

disconnects (fused or non-fused) and thermal overload

relays.

Motor protection and supply wire sizing must be suffi-

ciently sized to accommodate the increase in motor amp

draw due to lower temperatures and increased air density.

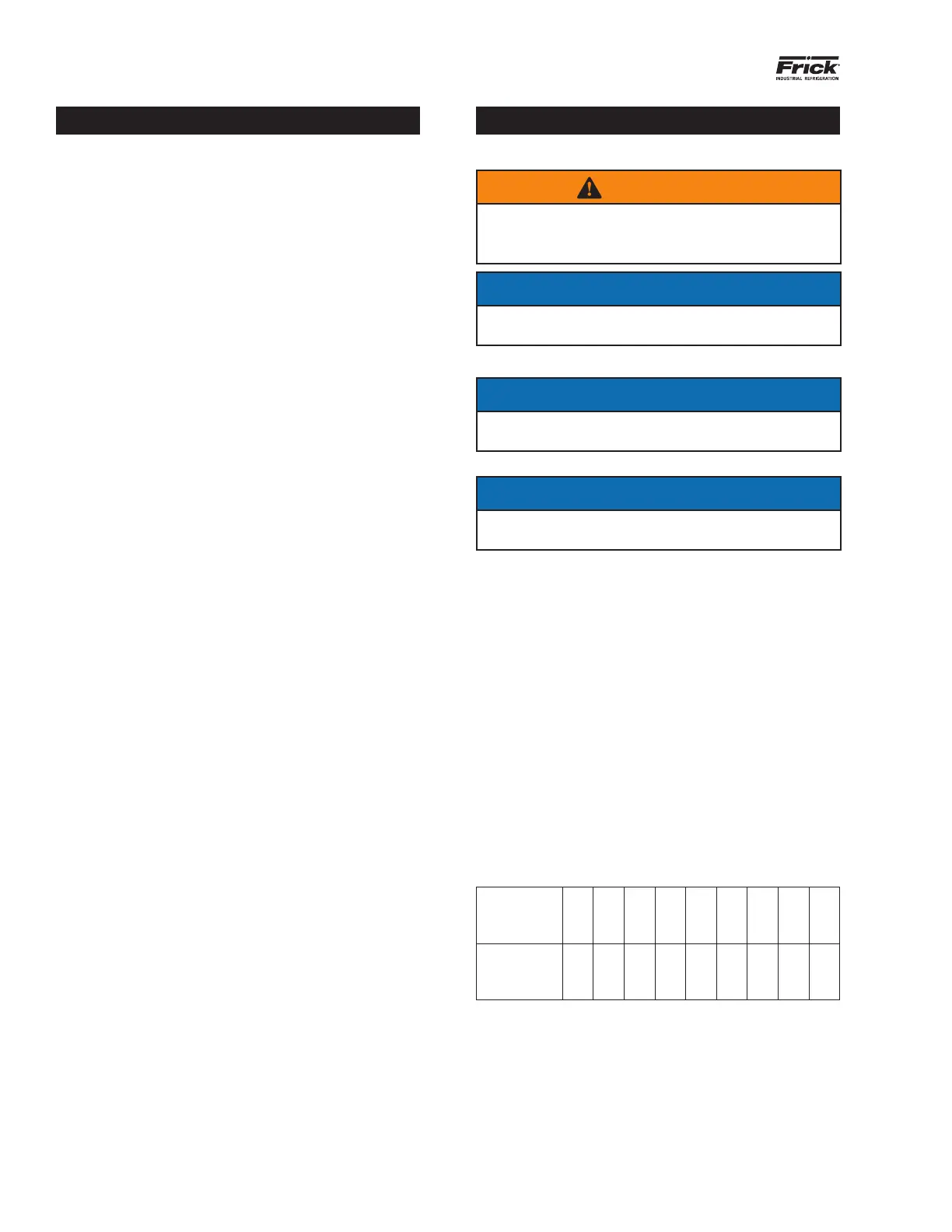

See Table 2.

Table 2: Motor amperage correction factor vs.

room temperature

Room

temperature

°F

40 30 20 10 0 -10 -20 -30 -40

Amperage

correction

factor

1.06 1.09 1.11 1.13 1.15 1.18 1.21 1.24 1.27

Before operating the unit check all wiring connections,

including factory terminals, because these could vibrate

loose during shipment.

Units are shipped with each of the motors wired to a ter-

minal strip within a common junction box – unless other-

wise requested. It is the installing contractor’s responsibil-

ity to provide the power supply wiring to the unit terminal

block or disconnect switch option.

Loading...

Loading...