610.020-IOM (NOV 19)

Page 8

EVAPORATOR AND AIR COOLER

INSTALLATION - OPERATION - MAINTENANCE

Defrost

All air coolers operating with coil surface temperatures

beneath freezing (32°F [0°C]) experience some form of

frost accumulation. In order to maintain the performance

of the coil, it is imperative that some form of defrosting

is incorporated into the system. The defrosting of the coil

is accomplished by air, for rooms above 36°F (2.2°C), hot

gas, electric, or water. See Table 3.

AIR DEFROST

For applications where the room temperature is above

freezing, defrosting of the nned surface area is possible

by closing the liquid feed to the coil and allowing the fans

to continue running. The warmer air passing over the coil

melts the frost accumulation but the rate of frost melt is

dependent on the frost formation and room temperature.

Only use air defrost when the room temperature is above

36°F (2.2°C).

HOT GAS DEFROST

Most refrigeration systems incorporate a central compres-

sor room. This is an ideal source for hot gas and only re-

quires the piping to make it available for the evaporators.

The latent heat content of the vapor makes this method of

defrosting very effective and is essentially a by-product of

the refrigeration system. It is essential that not more than

1/3 of the evaporators in the system are defrosted

simultaneously.

Reverse cycle defrost is not recommended for non–

commercial applications. Always use forward cycle, which

requires a three-pipe arrangement at the evaporator, the

third pipe being the hot gas supply line. The hot gas ow

through the unit must always be a series arrangement,

rst through the pan section and then into the coil from

top to bottom. For DX applications using a distributor,

the hot gas feed into the coil must always be through the

distributor, not reverse cycle.

Incorporate a soft start hot gas solenoid valve in the valve

station into evaporators with capacities greater than 15

tons (52 kW). This valve allows the coil to ease up to the

hot gas pressure and prevents problems such as check

valve chatter, liquid hammer, and piping vibrations.

The pump out phase is critical to optimum defrost per-

formance. Additionally, if liquid is still present in the tubes

when the hot gas enters the coil, condensate induced

hydraulic shock is possible, which can have severe conse-

quences including ruptured pipes.

Hot gas piping located within the refrigerated spaces or

outdoors in cold climates must be insulated. It is also

recommended to have liquid drainers installed in these

lines to prevent liquid condensate entering the evaporator

during the defrost phase.

The hot gas mass ow supplied to the evaporator is de-

pendent on the capacity of the unit and the hot gas pres-

sure entering the evaporator. It is insufcient hot gas ow

to the evaporator that results in poor defrost performance,

rather than insufcient hot gas pressure and temperature.

See Table 4 for recommended hot gas pressures at the

evaporator.

The sequence of hot gas defrost operation and recom-

mended stage duration is indicated in Table 5.

ELECTRIC DEFROST

For DX halocarbon applications the most common method

of defrost is with electric heater rods. The heaters are

placed in both the coil and the pan section. The heater

rods are installed within support tubes in the coil bundle

and held in place with C clips, which are positioned so that

there is sufcient space for the rods to expand and con-

tract due to the thermal changes. All heater rods require a

pull space for removal or replacement that is equal to 0.8

x the coil length.

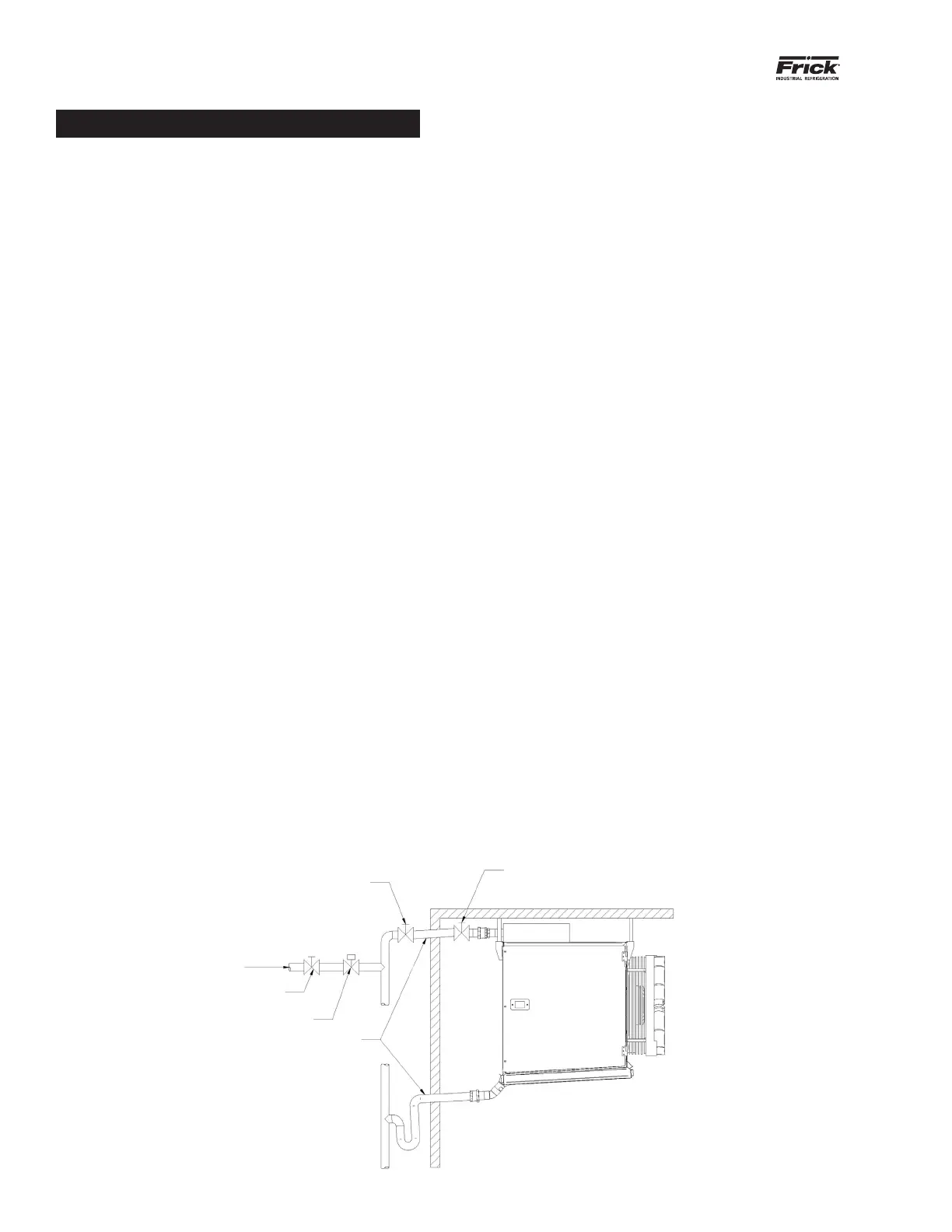

Figure 1: Drain line and water defrost piping

Regulating valve

Main water supply

Shut-off valve

Soleniod valve

Water defrost supply lines and

drain lines pitched 3/8 in. per ft

Regulating valve at each defrost/

unit connection

Loading...

Loading...