7

a480man.en_teil1

7 MAINTENANCE

Depending on the working conditions and the use of the tool the following maintenance has to be made

periodically:

7.1 Air - unit

• Checking the air-pressure daily.

• Checking oil-level daily.

• The water separator must be emptied before it is full (unless automatic).

• The filter has to be cleaned following the instructions of the manufacturer of the air- unit.

Oil for the air-unit

HL or CL ISO-VG 10

7.2 Cleaning

If impact of dirt and dust is considerable and if painted straps are used the feed wheel must be cleaned

regularly. Normally it is sufficient to blow out this part by using an air gun.

7.3 Lubrication

The worm gear is filled with MOLYKOTE BR 2 PLUS. Use the same type of grease after repairs.

When being exchanged, all valve parts and other movable parts have to be greased with grease of type

ESSO BEACON 2 or with any equivalent product.

The diaphragm must always be rubbed with TALCUM before being installed.

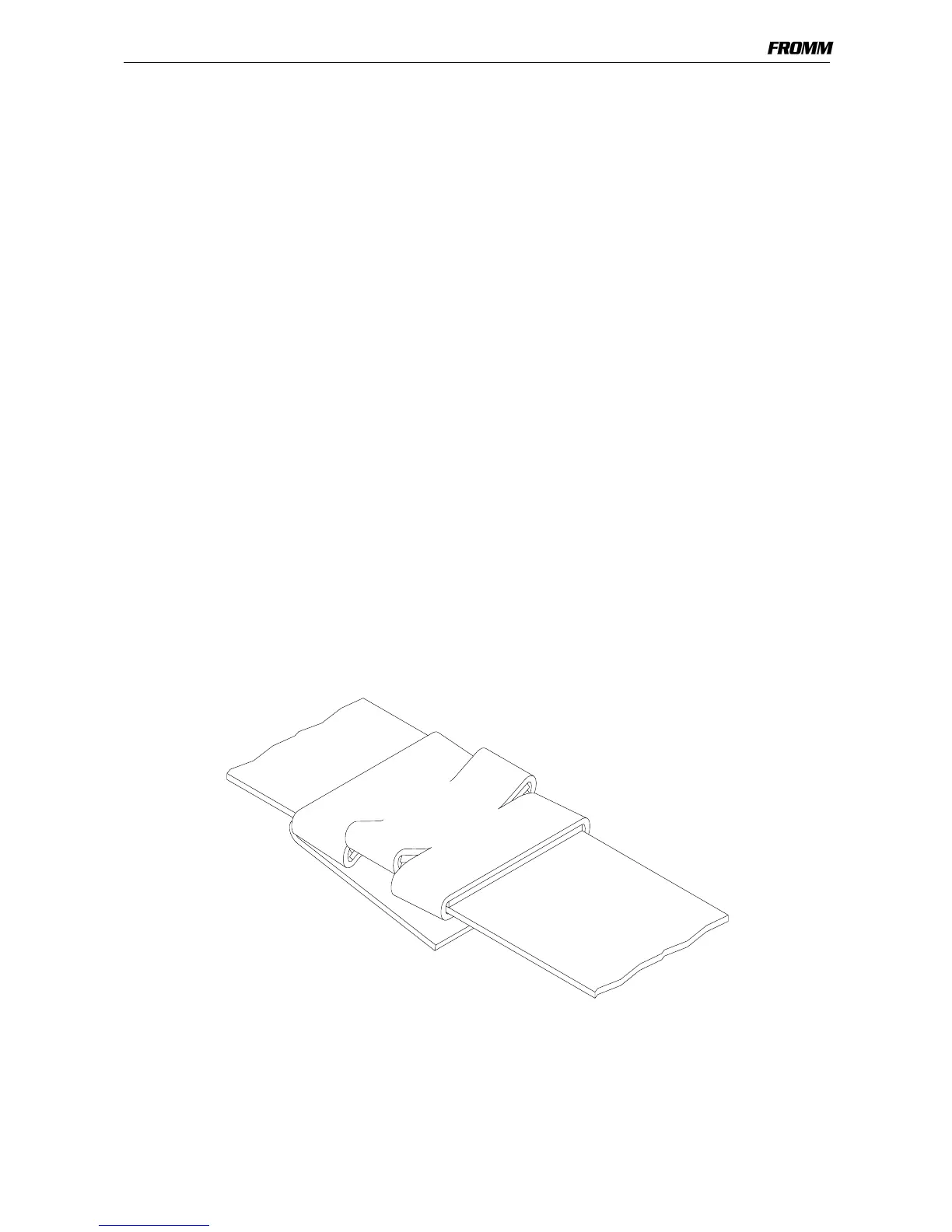

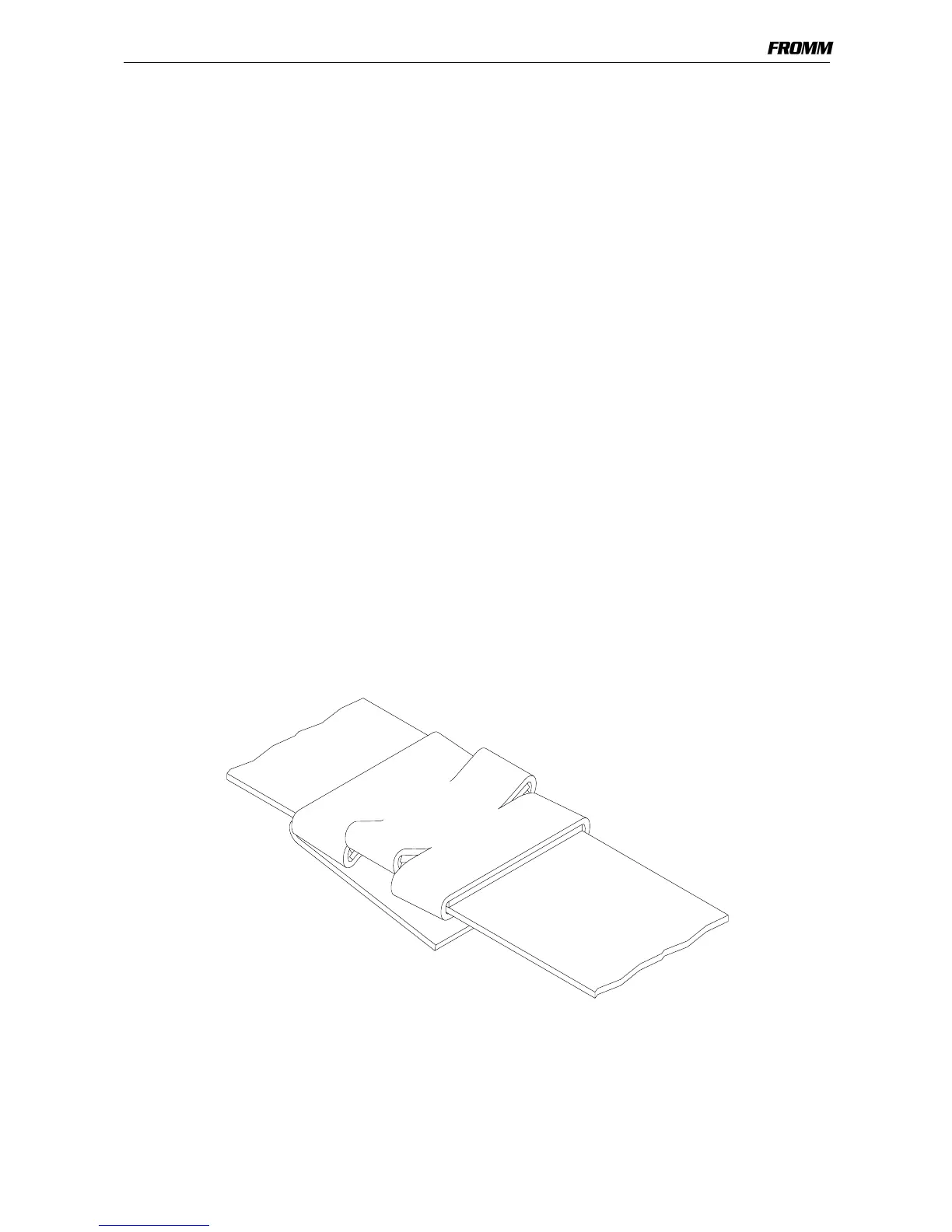

8 JOINT CONTROL

A regular control of the joint is necessary. The joint can be checked visually and the person controlling can

easily judge the quality of the joint. Following illustration shows a proper joint:

Sharp edged or misformed joints which do not appear as shown have to be taken away from the load

immediately. The tensile strength of these joints is insufficient and they could cause serious injury.

Having faulty joints proceed as follows:

• Checking the sealing cycle for improper use.(see OPERATION)

• Having faulty joints in spite of proper use, inspect the tool for worn or damaged parts. In case of

wearing out or damaging replace tool parts as needed.

Loading...

Loading...