- 0.2–2 Hz

- 2–20 Hz

- 20–200 Hz

- 200–2000 Hz

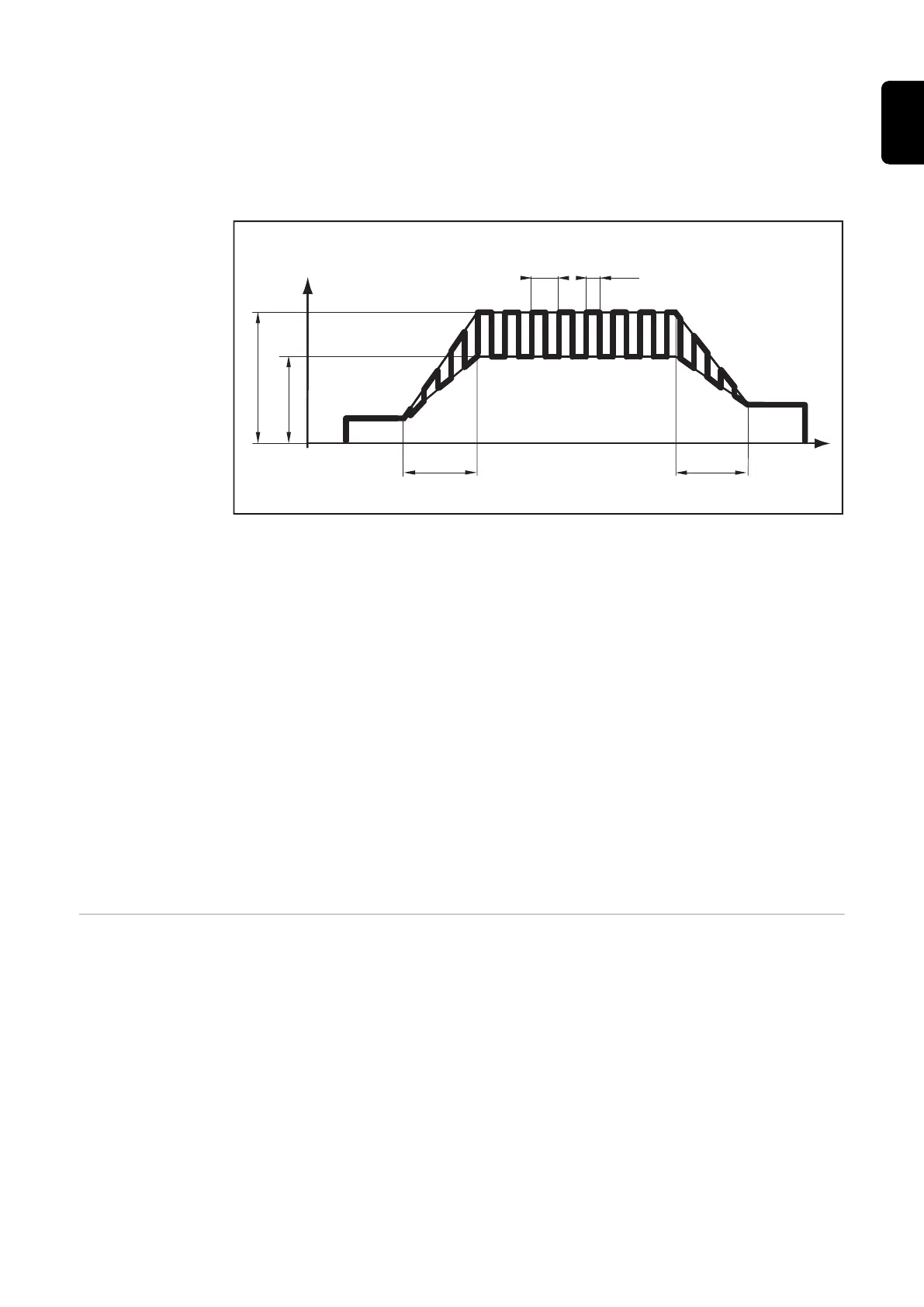

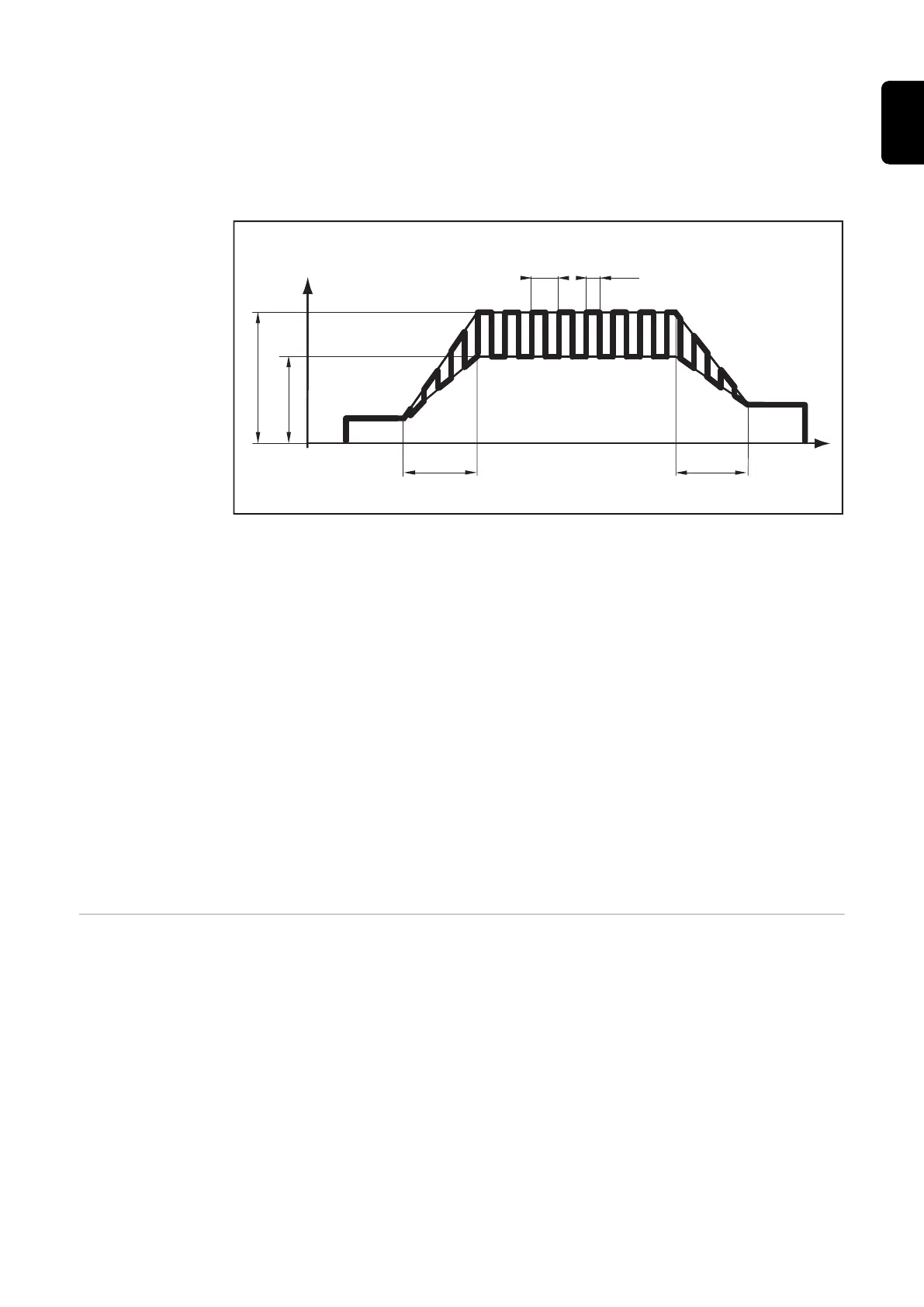

The illustration below shows TIG pulsing with the DC welding process selected.

)3

GF<

,

,

W

W

XS

W

GRZQ

,

6

,

(

,

TIG pulsing - welding current progression curve

- IS ........... Starting current

- IE ........... Final current

- tUp ........ UpSlope

- tDown ... DownSlope

- F-P ........ Pulse frequency

(1/F-P = time between two pulses)

- dcY........ Duty cycle

- I2 .......... Base current

- I1 .......... Main current

(6) Power source connection socket ... for connecting the remote control to the

power source

(7) Foot remote control connection socket ... for connecting the foot remote con-

trol TR 52mc. Particularly advantageous for manual TIG welding. The pulse

welding current can be changed during the welding process (e.g. variable mater-

ial thickness).

TIG foot remote

control TR 52mc

The TIG foot remote control TR 52mc is especially suitable for welding complicated

workpiece shapes.

51

EN-US

Loading...

Loading...