Every 8 hours:

1. Grease the rotor support (see fig. 15) and the roller support (see fig. 17), the

driveline cross and bearings and the telescopic tubes. Apply two or three shots

of grease to the driveline cross and bearings and the telescoping shafts. Apply the

same amount to the rotor and roller bearings.

2. Gearbox oil level: Check gearbox oil level, it should be between

1

/

2

and

2

/

3

full. If

needed add either SAE 90 wt. or SAE 140 wt. gear oil.

Whenever the hopper is used for fertilizer spreading it is extremely important to

carefully clean out the hopper and wash the machine with hot water. Do not

forget that fertilizer is highly corrosive and should be not left in the hopper any

longer than necessary.

MAINTENANCE 32 FRONTIER

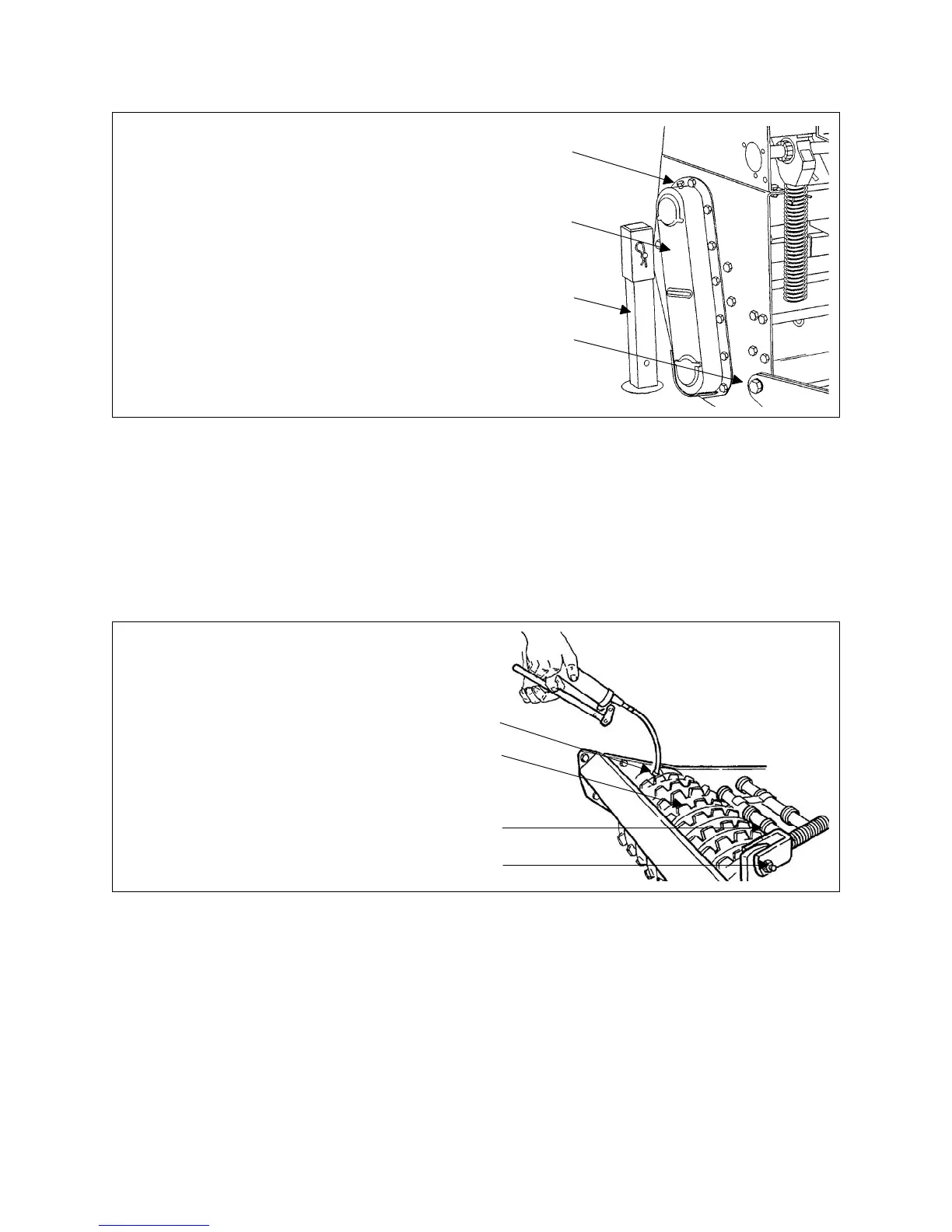

A

ERATOR-OVERSEEDER OPERATOR’S MANUAL

1

2

3

4

Fig. 16

1. chain case grease access plug

2. chain case

3. stand

4. side plate

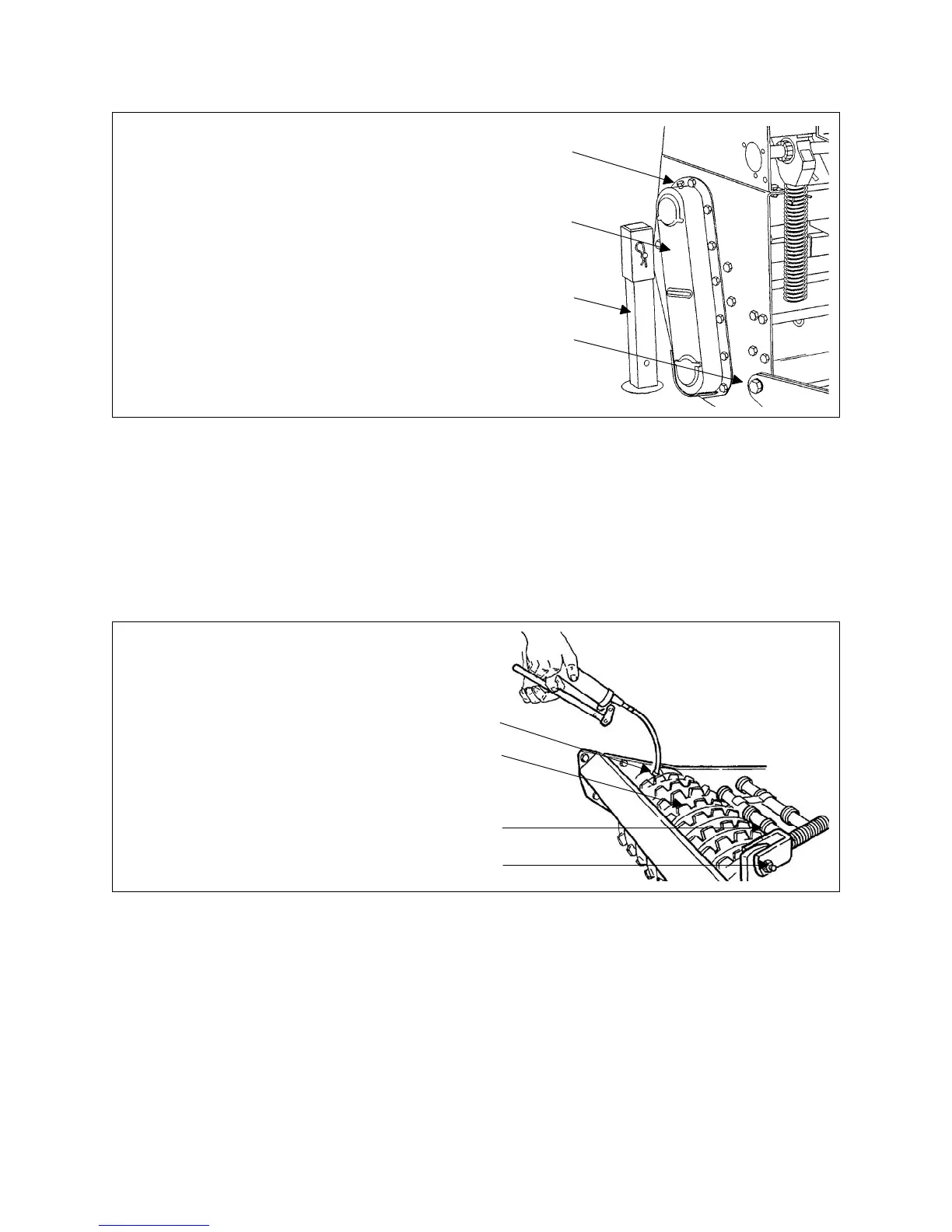

1

2

3

4

Fig. 17

1. greasing the roller support

2. rear roller

3. tickler tines

4. roller adjustment turnbuckle

Loading...

Loading...