PRODUCTION AND QUALITY CONTROL

22

SLUG PRO START-UP PROCEDURES

PROTECTIVE EYEWEAR AND GLOVES REQUIRED!

1. Check Chemical Cylinders.

a) Check Level Gauge on A and B cylinders to ensure sufficient chemical supply.

*It is recommended to change chemical cylinders when chemical level reaches 5%. (10% for Pipe Systems)

b) Check Temperature Gauge on Filter Assembly. 80°F (21°C) is Minimum Operating Temp.

2. Turn on Nitrogen (N

2

) Cylinder.

a) Check Reserve. (Minimum 500 psi/34.5 bar required)

b) Check for leaks.

c) Check regulator pressures. (Set Point is 240-245 psi/16.5-16.9 bar. Do not exceed.)

*Regulators are set during initial setup. Adjustments to regulators are rarely, if ever, needed.

3. SLOWLY Open Nitrogen Ball-Valves at Cylinders to pressurize.

4. Once Cylinders are at pressure, SLOWLY open Chemical Ball-Valves at Cylinders.

5. Turn Timer and Heat Box ON.

6. Connect Air Hose to Air Supply. Turn Air Supply ON.

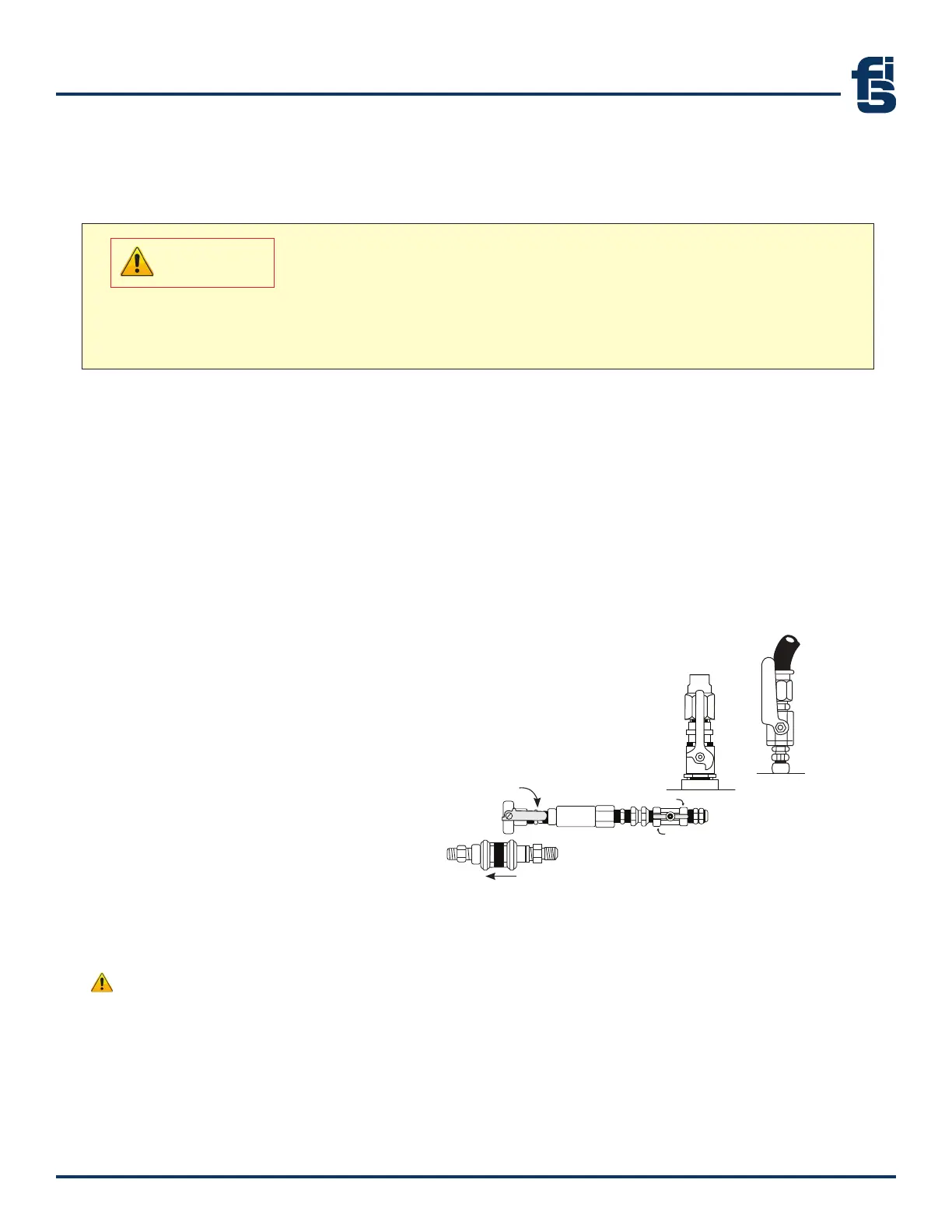

7. Grease SLUG PRO Unit through Grease Zerk (1-2 pumps).

8. Open all four Ball-Valves at Dispensing Head.

9. Push Slide-Safety Valve forward to ON position.

IMPORTANT: AT THIS POINT THE EQUIPMENT IS READY TO DISPENSE CHEMICAL!

10. Perform Quality Control Procedures.

a) Perform and Check Ratio.

b) Connect Mix Tube. Take 6 or 10 second bag shot for throughput.

c) Fill Out Quality Control Sheet.

11. Begin Production.

O

N

O

N

IMPORTANT

Read through all the steps before starting procedure. Please refer to the appropriate

SDS for proper safe handling including the use of safety glasses, protective gloves,

and respirator protection where needed.

For any reason if you do not understand, or are uncertain of any or all procedures and instructions given to you

by Foam Supplies, Inc. and its representatives, please contact our Application Specialist before attempting

procedures. We will be happy to assist.

www.foamsupplies.com | www.ecomatetechnology.com | 1.800.325.4875

Loading...

Loading...