41S_Rev01

Basic Operation

Splicing procedure

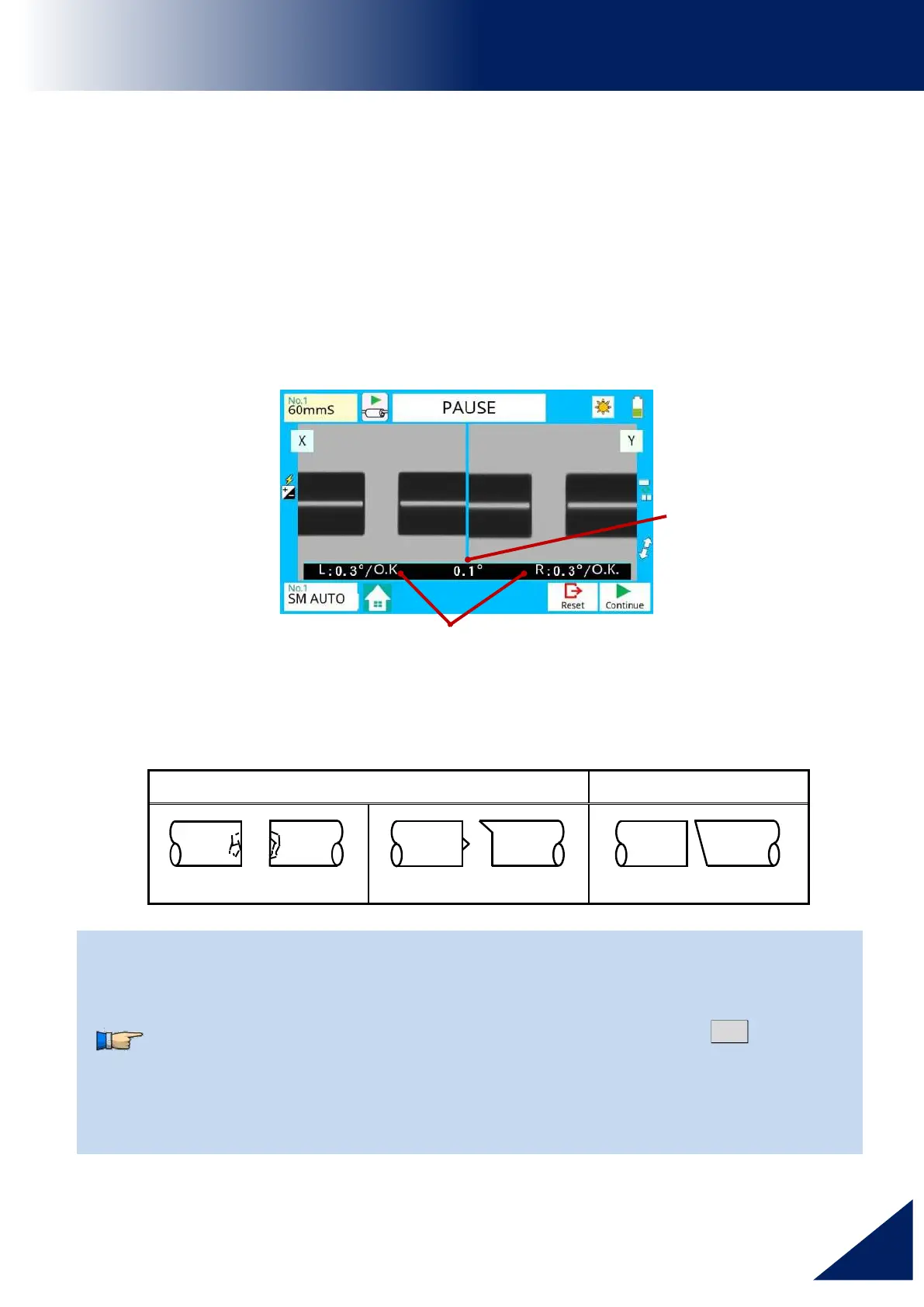

To make a good splice, the optical fiber is observed with the image processing system

equipped in the 36S/37S/38S/41S. However, there are some cases when the image

processing system cannot detect a faulty splice. Visual inspection with the monitor is often

necessary for better splicing yield. The instruction below describes standard operating

procedure.

1. Fibers loaded in the splicer move forward toward each other. The fiber forward

motion stops at a certain position shortly after the cleaning arc is performed.

2. Next, the cleave angle and end-face quality are checked. If the measured cleave

angle is greater than its set threshold or fiber chipping is detected, the buzzer will

sound and an error message warns the operator.

3. If no error message is displayed, the end-face conditions are used for visual

inspection as shown below. If observed, remove the fiber from the splicer and

repeat fiber preparation. These visual defects may cause a faulty splice.

The pause after cleave angle check and fiber alignment can be “disabled”.

See section [Splice Settings] for detail.

The cleave angle threshold can be changed. See section [Splice Menu].

The cleave angle error message can be ignored by pressing SET

key to go on

to the next step. To disable the cleave angle error. See section [Splice

Settings] for detail.

Cleave angle, during the splicing operation can be hidden. See section

[Splice Settings] for detail.

Left and Right cleave angle

Loading...

Loading...