AR-PRO – AC LINE VOLTAGE REGULATOR

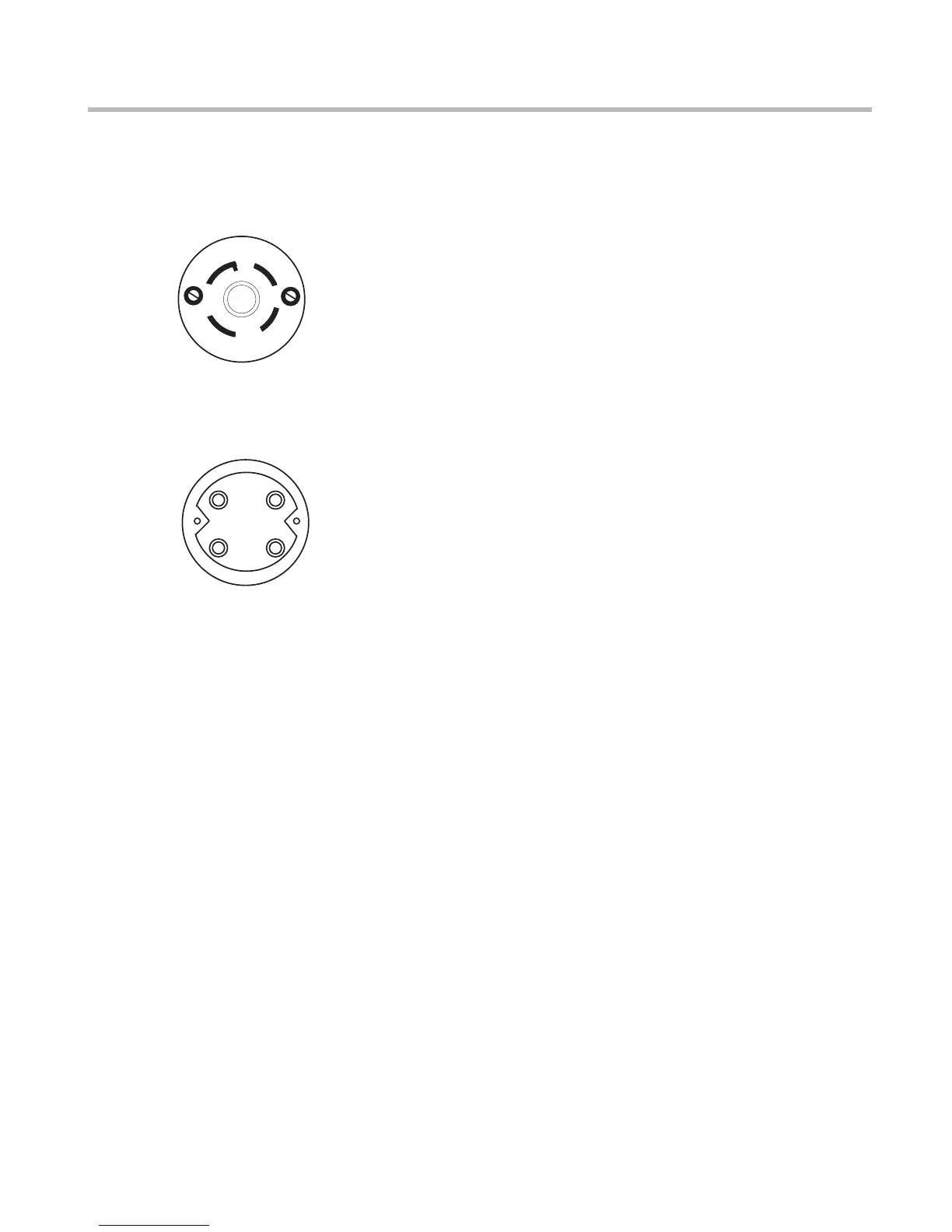

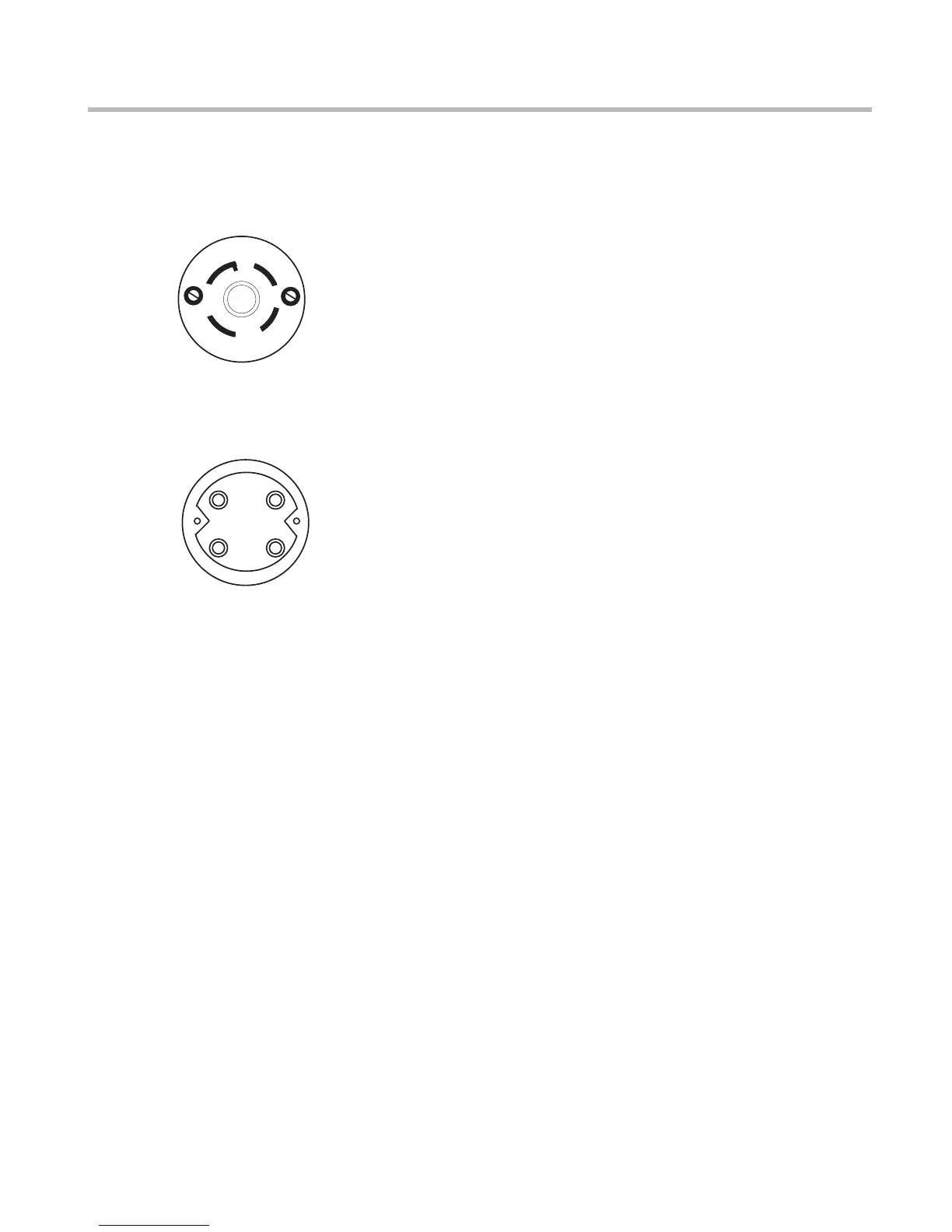

Refer to the following diagrams for wiring the twist-lock

All wiring confi gurations except North America

Wire hot lead to X (black in North America; black,

brown, or black with white stripes in Europe). Wire the

neutral to W (white in North America; blue in Europe).

Wire the equipment ground to G (green in North Amer-

ica; green with yellow stripes in Europe).

Wire the two hot leads to

X and Y (black, and white or red), and the equipment

ground to G (green). Since the USA 220-240 doesn’t

use a neutral, you don’t need to wire it.

because of the lack of a neutral, it is essential that

all equipment powered by an AR-PRO be properly

grounded! Never cut off the power cord ground pin

or use a “cheater” adaptor on any of your equip-

ment. Output neutral will have voltage.

When dealing with high currents such as those handled

by the AR-PRO, the supply cable itself must be con-

sidered part of the load. As such, the length, gauge,

and temperature rating of the insulation must be taken

into account. The minimum wire gauges we suggest

may not be large enough when the cable run is longer

than about 20 feet (7 meters). The smaller the cable

conductors are, the more fl uctuation of input voltage

there will be. This is due to the greater voltage drop.

For example, the recommended minimums will result

in a drop of approximately 1.0 volt for each 30 feet (10

Increasing the cable by one AWG size will reduce the

drop to 1 volt per 45 feet (15 meters). Bigger is defi -

nitely better in this case.

The connector used at the source end should be rated at

least 250V-15A for high range operation, or 120V-30A

for low range operation. If in doubt, consult a licensed

electrician when installing your AR-PRO.

Because its toroidal transformer design has minimal

magnetic leakage, the AR-PRO may be successfully

installed in the same rack as other equipment. Though

small for a device capable of handling 30 amps, this

leakage is not zero. It is wise to avoid positioning the

AR-PRO immediately adjacent to equipment which

handles low-level signals, such as preamps, mike

mixers, etc. Power amps or other high level devices

would make better “rack neighbors.” If excessive hum

or buzz is present in the audio signal, you may be able

to reduce or eliminate it by leaving more empty spaces

Suggested rack locations would be near the top or bot-

tom, with the bottom preferred due to the AR-PRO’s

weight. Because the AR-PRO generates considerable

heat, leaving at least one empty space above and one

below is recommended to aid in convective cooling. As

with any rack-mount equipment, be sure to use 10-

32 machine screws for mounting in the rack’s tapped

holes. In particular, beware of 10-24 screws, which may

fi t, if forced, but will strip the threads. To avoid marring

the front panel fi nish, use plastic washers under the

Adjustable rear rack ears (RPM-2, sold separately)

permit the most secure rack installation. It is essential

to use them when mounting the AR-PRO in any rack

position other than the bottom. If your rack has no

rear rack rails, you may wish to install them or at least

substitute securely mounted blocks of wood.

The rear rack ears can be attached to the wood blocks

with wood screws. They can be adjusted to any rail-

to-rail spacing from 17 to 18.5 inches by loosening the

three adjusting screws on each side, sliding the ears to

a new position, and retightening them.

125/250V

.

30A.

NEMA

L14-30

G

W

X

Y

(EQUIPMENT�

GROUND)

(NEUTRAL)

(HOT LEAD)

(USA 220-240 ONL

Y)�

FRONT VIEW

REAR VIEW

G

W

X

Y

Loading...

Loading...