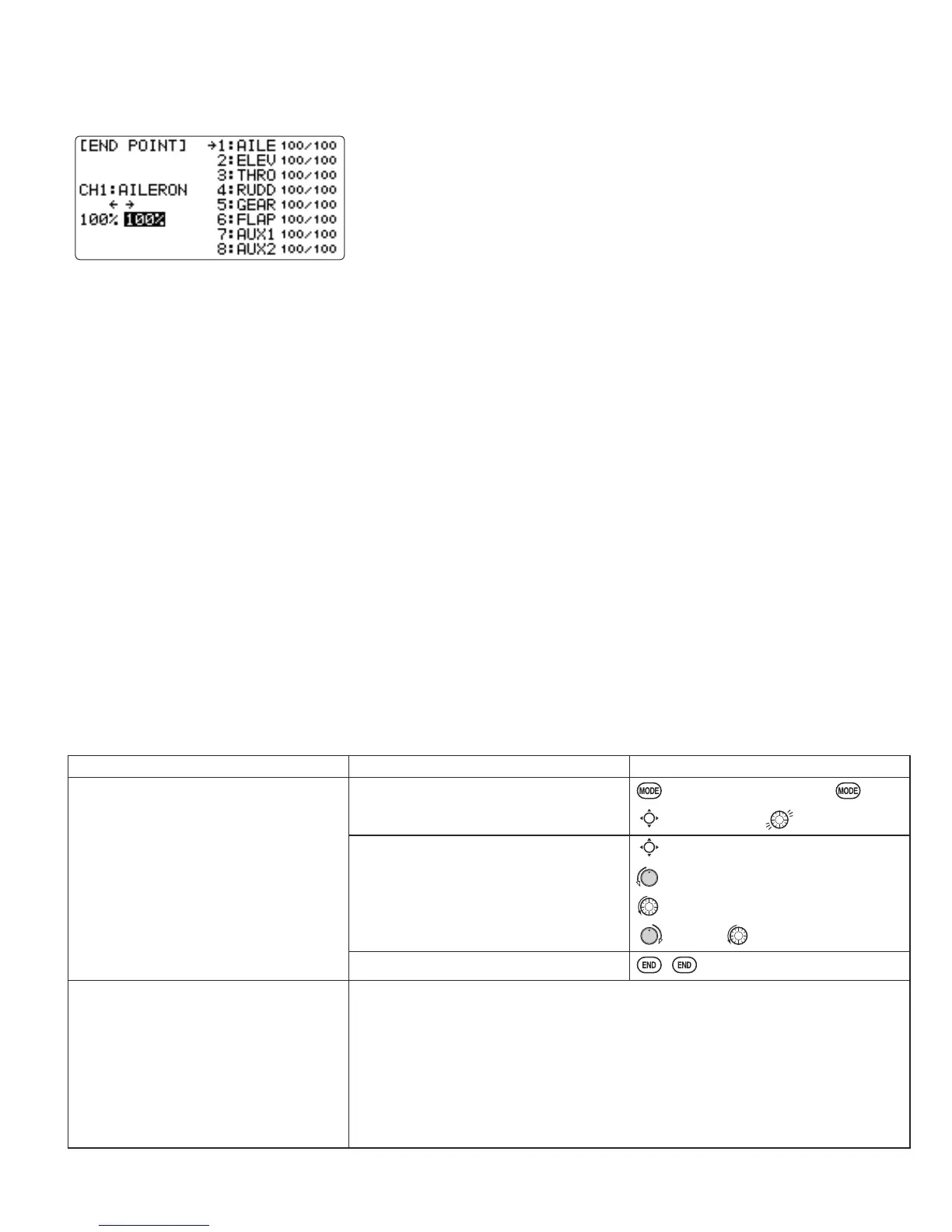

End Point of servo travel adjustment (

END POINT

, also called EPA): the most flexible version of travel adjustment

available. It independently adjusts each end of each individual servo’s travel, rather than one setting for the servo that

affects both directions. Again, for CCPM helicopters, be sure to see

SWASH AFR

(see p. 95) prior to adjusting end points.

Adjustability:

• Can set each direction independently.

• Ranges from 0% (no servo movement at all) to 140%. At a 100% setting, the

throw of the servo is approximately 40° for channels 1-4 and approximately 55

° for channels 5-8.

• Reducing the percentage settings reduces the total servo throw in that direction.

Examples:

• Adjust the throttle high end to avoid binding at the carburetor, and low end to allow for proper carburetor closure.

$GMXVWÀDSVRXSWUDYHOLVRQO\VXI¿FLHQWIRUVWUDLJKWDQGOHYHOÀLJKWWULPPLQJZLWKIXOOGRZQWUDYHO

•

END POINT

PD\EHDGMXVWHGWRWRNHHSDVHUYRIURPPRYLQJRQHGLUHFWLRQVXFKDVÀDSVQRWLQWHQGHGWRDOVRRSHUDWHDV

spoilers.

• Retract servos are not proportional. Changing

END POINT

will not adjust the servo.

END POINT

adjusts only the individual servo. It will have no effect on any other servo that is operated in conjunction with

this servo via mix or preset programming such as

FLAPERON

,

AILEVATOR

, etc. This is so that each individual servo can be

FDUHIXOO\¿QHWXQHGWRDYRLGELQGLQJDQGRWKHUFRQÀLFWV7RDGMXVWWKHWRWDOWUDYHORIDIXQFWLRQVXFKDV

FLAPERON

, make

the adjustments in that function's controls. For CCPM helicopters, adjust the total travel of the function, such as collective

pitch, in

SWASH AFR

.

Adjust the linkage or the

END POINT

? It is nearly always best to adjust your linkages to get as close as possible prior to

utilizing

END POINT

. The higher the

END POINT

setting, the better position accuracy and the more servo power available

at nearly any position (except if using digital servos). Higher

END POINT

values also mean longer travel time to reach the

desired position, as you are utilizing more of the servo's total travel. (For example, using 50%

END POINT

would give you

only half the steps of servo travel, meaning every click of trim has twice the effect and the servo gets there in half the

time).

• end point (and moving the linkage) = torque, accuracy, but transit time to get there.

• end point (instead of adjusting linkages) = travel time, but torque, accuracy.

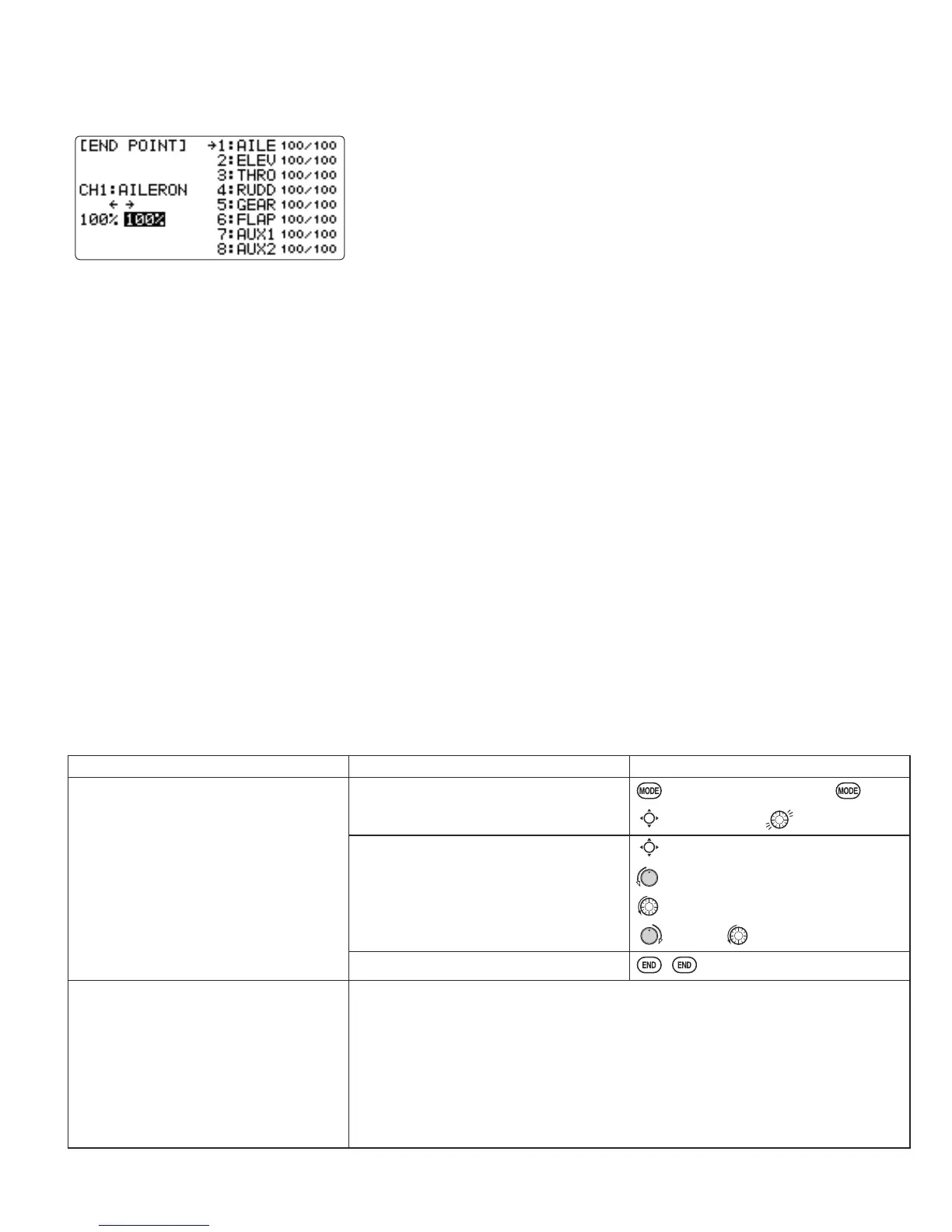

GOAL of EXAMPLE: STEPS: INPUTS:

Decrease the flap servo throw in the

upward direction to 5% to allow

WULPPLQJRIOHYHO ÀLJKWRQO\DQGGRZQ

travel to 85% to prevent binding.

Open

END POINT

function.

for 1 second.

(If

ADVANCE

, again.)

C

to

END POINT

.

Choose proper channel and move stick

or knob in direction you want to adjust

DQGVHWVHUYRWKURZ([ÀDSXS

C

to

FLAP

.

ÀDSFRQWURO>GHIDXOWLVVR(A)].

to

5%

.*

VR(A). to

85%

.

Close.

Where next? Go to

SERVO

GLVSOD\WRFRQ¿UPGHVLUHGHQGUHVXOWVHHS

0RYHDX[LOLDU\FKDQQHOVWRGLIIHUHQWGLDOVVZLWFKHVVOLGHUVVHHS

Set up

IDLE-DOWN

and

THR-CUT

WRVORZFXWWKHHQJLQHVHHS

6HWXSGXDOWULSOHUDWHVDQGH[SRQHQWLDO

D/R

,

EXP

): see p. 42.

6HWXSÀLJKWWLPHUVVHHS

Set up trainer functions: see p. 47.

Set up twin aileron servos: see p. 51.

Set up twin elevator servos: see p. 57.

*You can reset to the initial values by pressing the DIAL for one second.

Loading...

Loading...