Whole Machine Cleaning

Clean with a damp sponge or cloth

Do not immerse the air purifier in water

Do not disassembly fixed parts for cleaning

The air outlet with odor

The effect of dust

removal and purificaon

are not obvious, and

the air quality is not

significantly improved.

Too much noise

when running

The filter can’t fit in

The machine won't

turn on

Motor abnormalies

Motor turns plugging/

motor overheat protecon,

machine prompts, and

does not work

There are many polluon

sources in the room

It is suggested that the room

be venlated by opening

the window.

The filter is heavily polluted

The machine has no filter Install the filter

Clear the blockage or

move somewhere else

The filter is too dirty

Sundries in machine

The filter is inversely

installed

Filter cover or filter

not installed properly

Whether the installaon

is not firm enough

Clean or replace the filter

Remove debris

Adjust the filter in the correct

direcon and align it with the

boom slot

1.Re-install the cover and filter

2.Contact aer sales

service center

1. Unplug, cool for 1-2 hours

and reconnect

2.Contact aer sales

service center

Contact aer sales

service center

The machine is placed in a

narrow place or there are

obstacles nearby, which

affect the purificaon effect

Replace a new filter

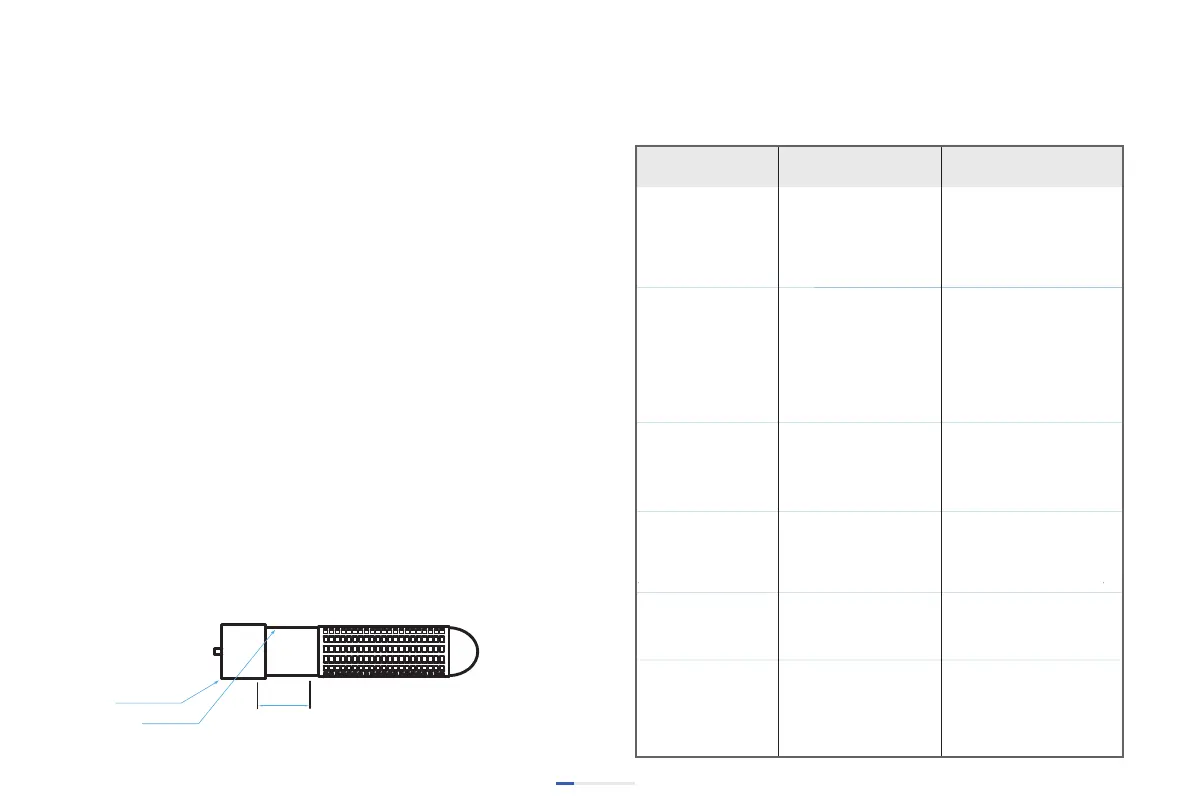

Cleaning of Condenser Mesh

1.Gently unscrew the quartz condenser.

2.Remove the OUTSIDE MESH of the condenser : if it seems to be

difficult, rotate the net slightly on the quartz condenser.

3.Clean the quartz condenser by using a moist cloth. WARNING :

Do not use detergents, soaps or similar products.

4.Check whether the condenser shows any cracks or other damage.

If so, replace it.

5.As soon as a whish layer appears on the metal grill inside the

condenser, it means the condenser should be replaced.

6.Reposion the metal mesh on the condenser, placing it over the

internal grill. WARNING : Leave a minimum distance of 6-7mm

from the boom of the condenser.

7.Check that SPRING TAB touches the metal MESH OUTSIDE and

pushes in against the glass of the quartz condenser.

COMMON TROUBLESHOOTING

METHODS

08

Mesh

Condensor

Base in PVC

6-7 mm

GAP

MALFUNCTION POSSIBILITY METHOD

Loading...

Loading...