Heating Boiler FUWI on Pellets can work in one of three modes:

1. Manual 2. Weather mode 3. Summer

1. Manual mode of work:

User with help of Operational Panel in submenu of Boiler set temperature for work of boiler

manually (purpose of buttons Increasing or Decreasing - see page 11)

Manual mode means only and exclusively manual settings by user of Boiler

temperature.

2. Weather mode of work:

Present mode requires installation of external temperature sensor as well as central heating

temperature sensor. Temperature of work is set by linear programmable heating curve, thanks to

that there is not necessity to adjust boiler temperature by hand in case of outside temperature

changes. In principally at night is always colder than during day time. It is temperature of boiler work

in external temperature function. Setting of boiler temperature is counted on basis of this curve and

is about 20

0

C higher.

SEE!!! Integral part of present manual is boiler automatics manual.

3. Summer mode of work:

Controller in this mode is used in summer to heat of warm usable water. In this mode (apart from

alarms) heating water pump does not start. Temperature of boiler is set manually using parameter

"set boiler temperature. ”.

If boiler temperature for warm water purposes is lower from temperature set in

manually mode or weather mode, then temperature set of boiler work will be this

higher temperature.

page 12

Very important items connected with proper functioning of Heating Boiler FUWI on Pellets are

proper settings in boiler controller (Operator Panel) in submenu: Burner, namely:

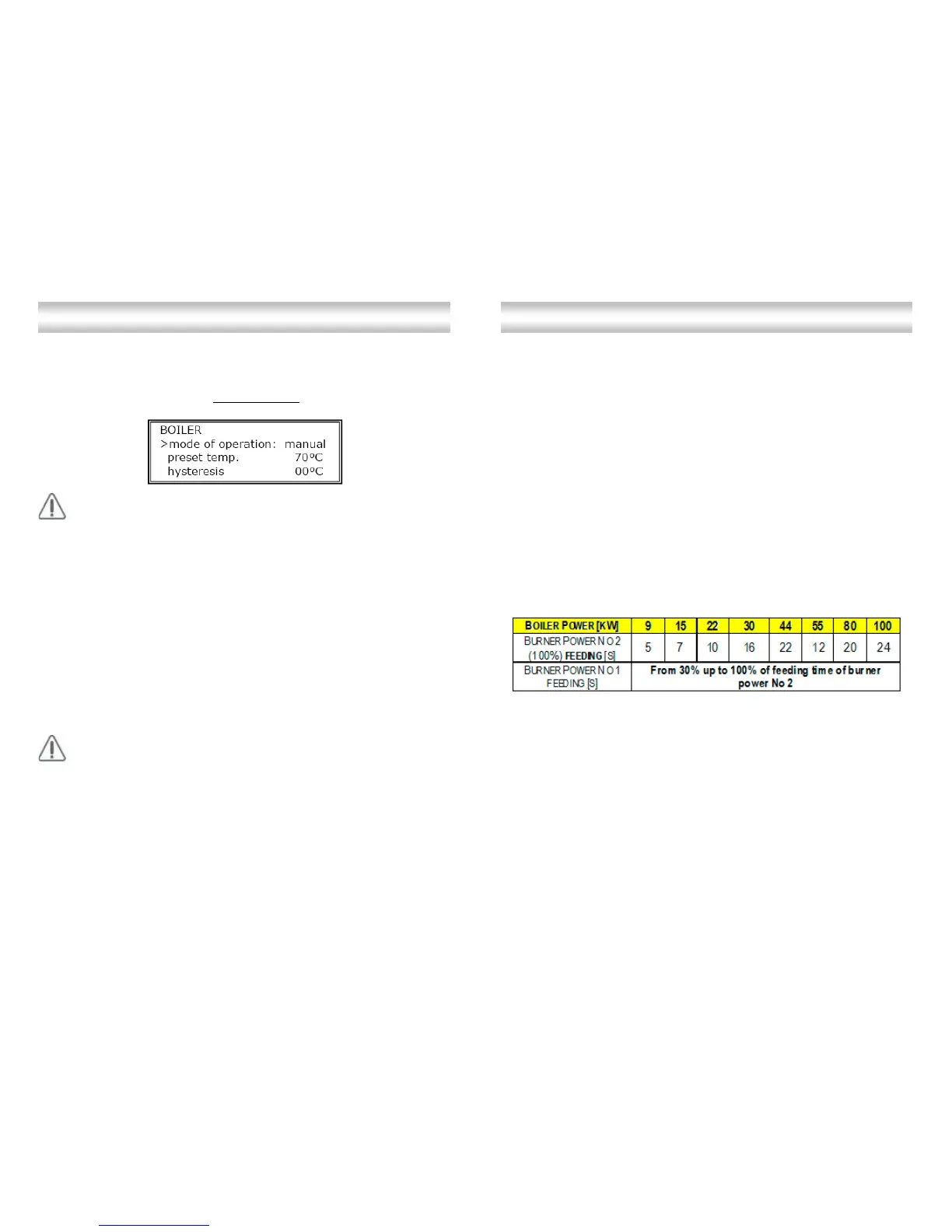

1. Feeding:

Fuel feeding is the very important process for boiler functioning. For more efficient setting of

standstill time for fuel feeding there is a preset the same parameter for all powers of boiler and

which is 10 seconds. It has to be set only time of fuel feeding. It has to be made in according to

Table Nr 1 (see below, page 15), but in individual cases it can be changed in range not more 1

or 2 second. It depends from caloricity and shape of used pellets fuel as well as from energetic

demand of heated object.

2. Blower:

It is the second very important factor of correct boiler functioning. Maximum use of fuel energy

depends on it, as well as correct ecological burning.

Settings of blower power in Heating Boiler FUWI on Pellets are individual and depend on many

external factors, influencing mainly on chimney draught. This adjustment should be made for every

boiler starting from ventilator settings (enlarging or reducing). This action has to be execute in

temperature of boiler minimum 600 - 700, than it is correct.

In situation of using Lambda Sensor adjusting the power of blower would be executed automatically

by enlarging or reducing air flow.

Table No. 1

3. Function of modulation of burner power:

The boiler is equipped with the function of modulation of burner power.

The above-mentioned function starts operating in the moment of achievement by the boiler

temperature set by user (eg. 60

o

) and starts reducing the power of the burner (by modulating

simultaneously the parameters of van and fuel feeding). The function of modulation will reduce

the burner power till the moment of achievement by boiler temperature about 5

o

higher and after

achievement of this temperature the boiler stops fuel feeding and burns fuel left on the burner

and afterwards switches off automatically or burner power will be enlarging in case of

temperature fall.

In relation with necessity of burning fuel to end and cleaning combustion chamber the boiler

should periodically be switched off.

In the boiler controller is applied the function of return to "factory presets”, permitting on restoration

of Manufacturer presets previously altered by user or servicemen.

page 17

Loading...

Loading...