Maintenance

The Turntable Spindle, motor and intermediate

wheel bearings being of the oil retaining type rarely need

lubricating. When however the need for oil is apparent

remove the turntable and sparingly lubricate these bearings

with a few drops of the oil supplied afterwards removing

all surplus and making sure that no oil is present on

the motor pulley or intermediate wheel before replacing

the turntable.

These oiling points are indicated on Diagram 5,

the oil recess in the top motor bearing being accessible

through one of the three holes in the aluminium disc of

the eddy current brake.

The motor must be in the switched off position

before removing or replacing the turntable. The turntable

is an accurate taper fit on its spindle and if difficulty is

experienced in removing it the spindle top should be given

a downward tap with a small block of wood, such as the

handle of a screwdriver, while the turntable is lifted.

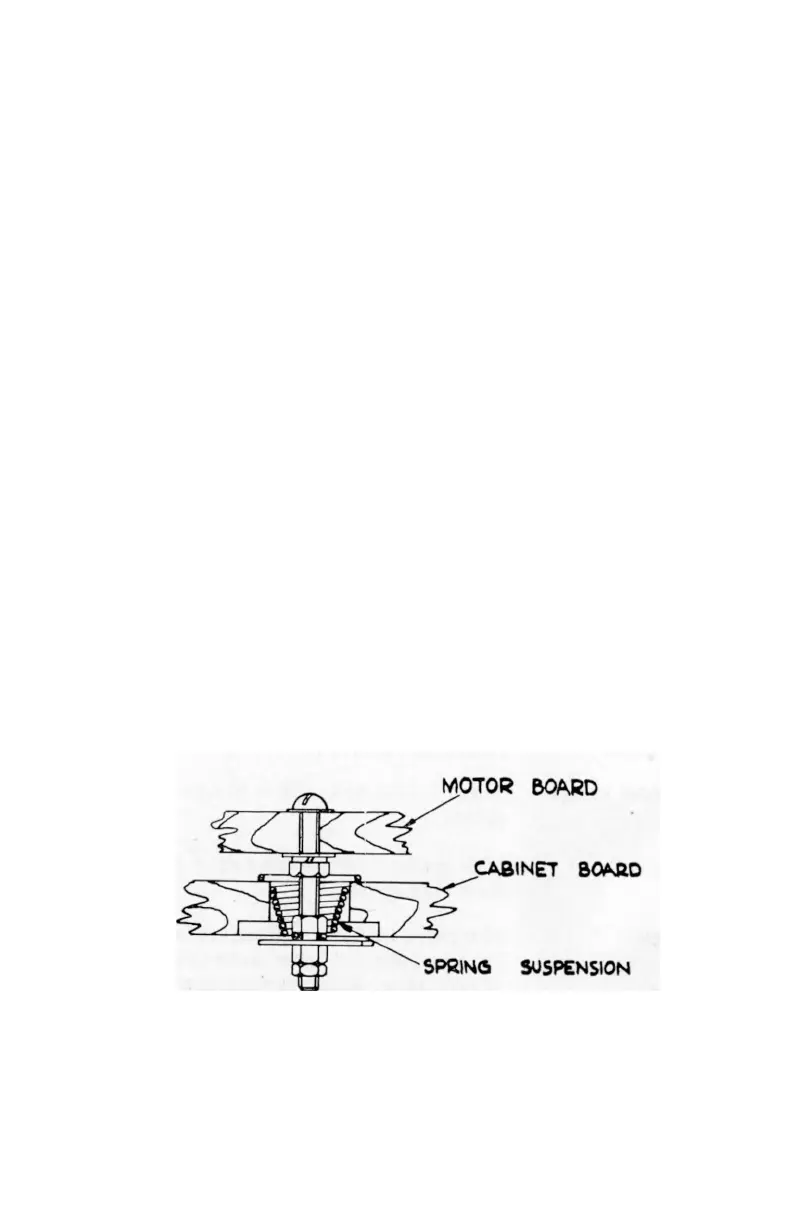

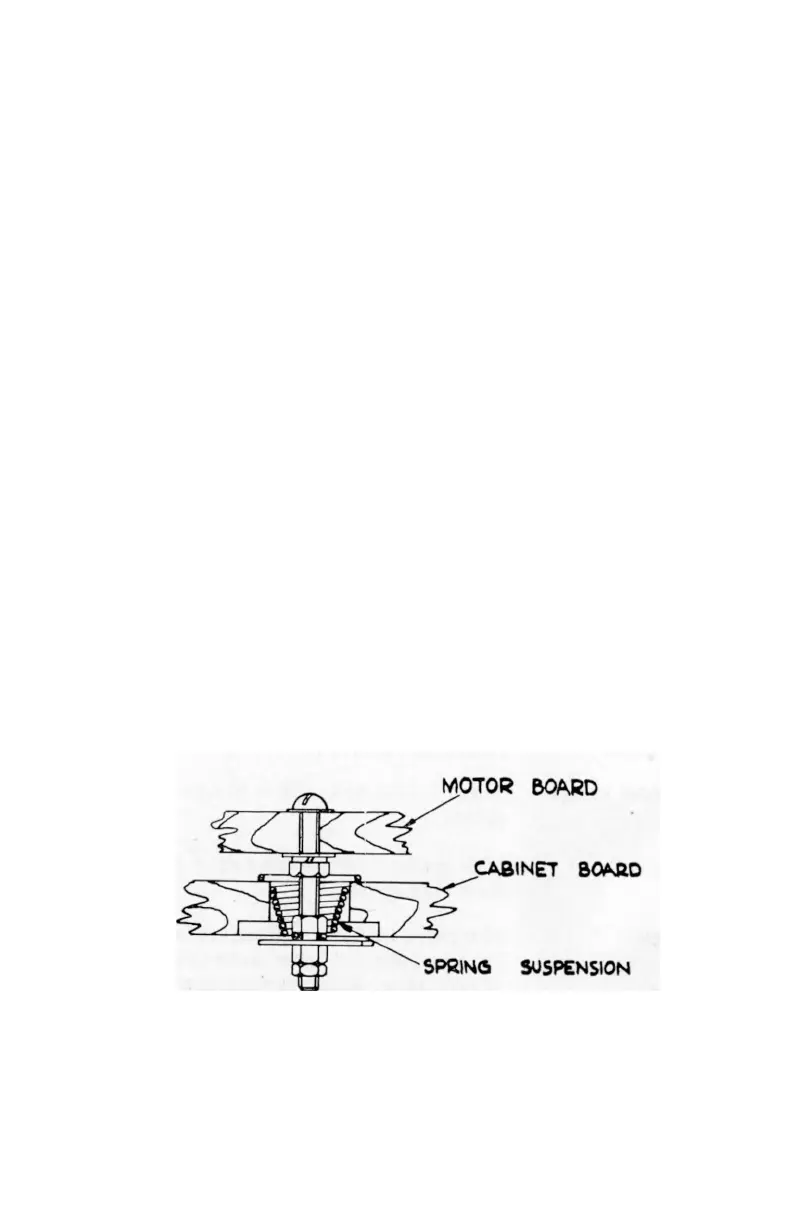

Diagram 6

12

Loading...

Loading...