14

Gates Corporation

NOTE: DO NOT measure on top of part number

stamps or ridges.

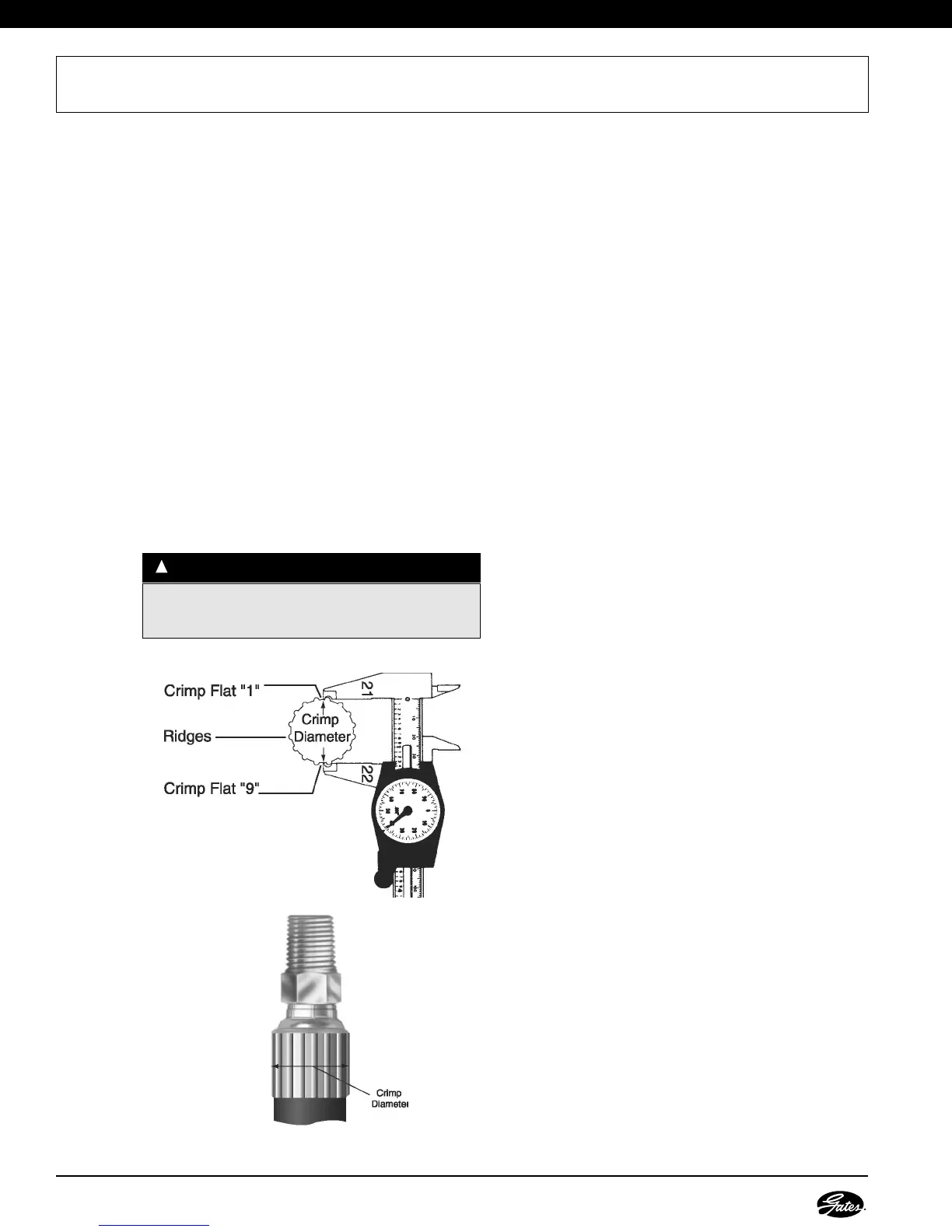

1. Measure crimp diameter.

• Using Gates calipers (Product No. 7369-1320/

Part No. 78217), measure halfway between

ridges. (Fig. 1) To be sure crimp diameter is being

properly measured, mark a crimp flat. Beginning

with that flat, count 9 flats to get the diameter. Be

sure caliper fingers DO NOT touch ridges or part

number stamps.

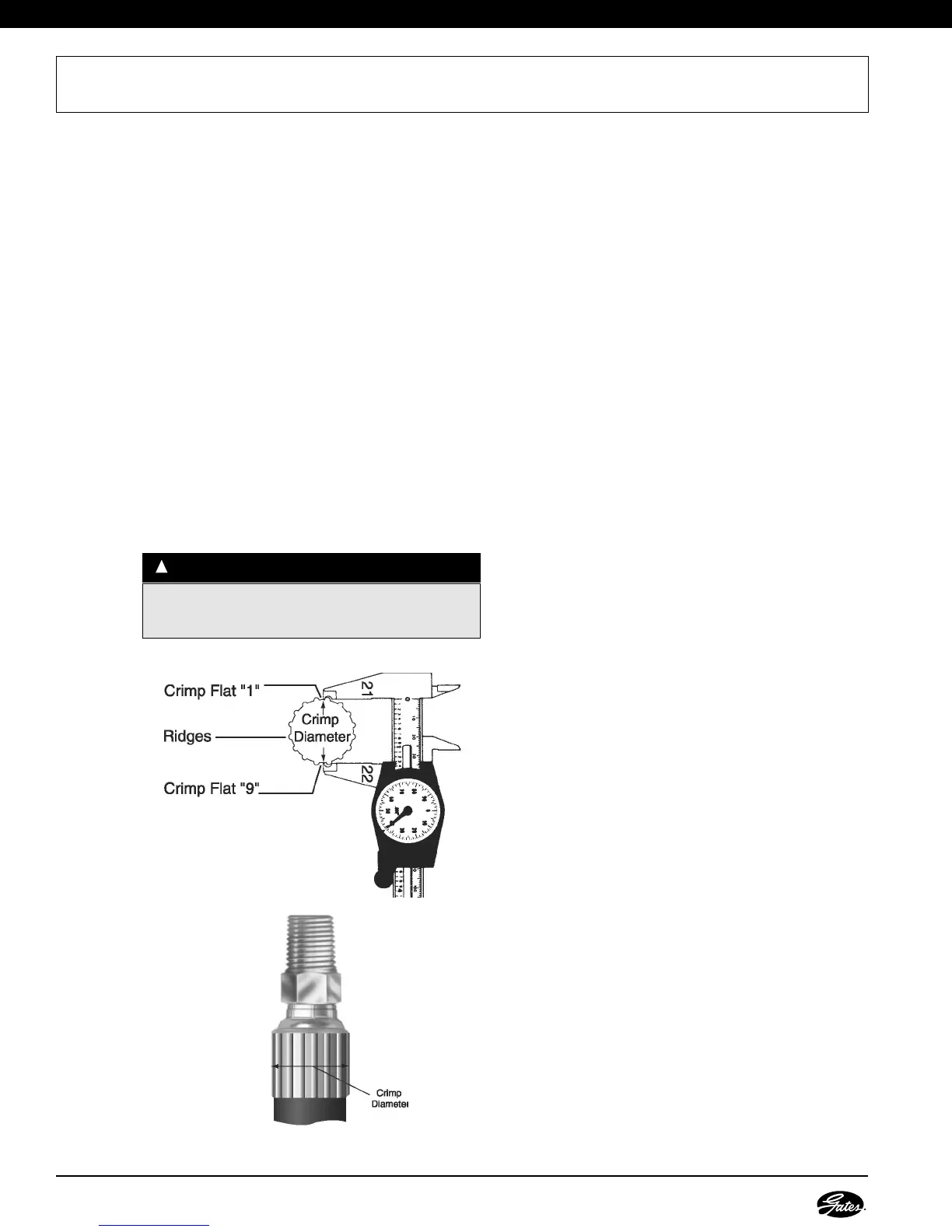

• Measure halfway between the ends of the

crimped portion of the ferrule. (Fig. 2)

2. Check crimp diameter.

• The measured crimp diameter must be within

0.010" of the published crimp diameter.

• Should the actual crimp diameter not be within

specified crimp tolerance, the assembly MUST

be discarded.

MEASURING AND ADJUSTING CRIMP DIAMETERS

WWAARRNNIINNGG

::

Protect the safety of people using your assemblies!

Your measured crimp diameters MUST be in tolerance

range as listed in the Gates Crimp Data Manual.

!

3. Adjust the crimp diameter (if necessary).

• If crimp diameter is not within specified crimp

tolerance, an adjustment to the crimp setting

needs to be made.

• To obtain a smaller crimp diameter, change dial

vernier setting to a smaller number.

• To get a larger crimp diameter, change dial

vernier setting to a larger number. Changing the

dial vernier number by approximately .02 will

change crimp diameter .001".

• After the correct diameter is achieved, record this

new setting in your crimp data manual for future

reference.

4. Multiple crimps.

• When crimping multiple assemblies, check every

tenth crimp to ensure diameter is within accept

able range (± 0.010").

• Discard those outside the specified tolerance.

Loading...

Loading...