20

Gates Corporation

TROUBLE SHOOTING

Troubleshooting Guide

All equipment is tested for proper performance

before it is shipped from the factory. However, if you

experience any difficulities, check the list below to

help restore equipment to proper operating standards.

WWAARRNNIINNGG

::

• Avoid electrical shock or hydraulic related injury!

• Disconnect crimper from power source before

removing control panel, loosening hydraulic tubing

or removing any components.

!

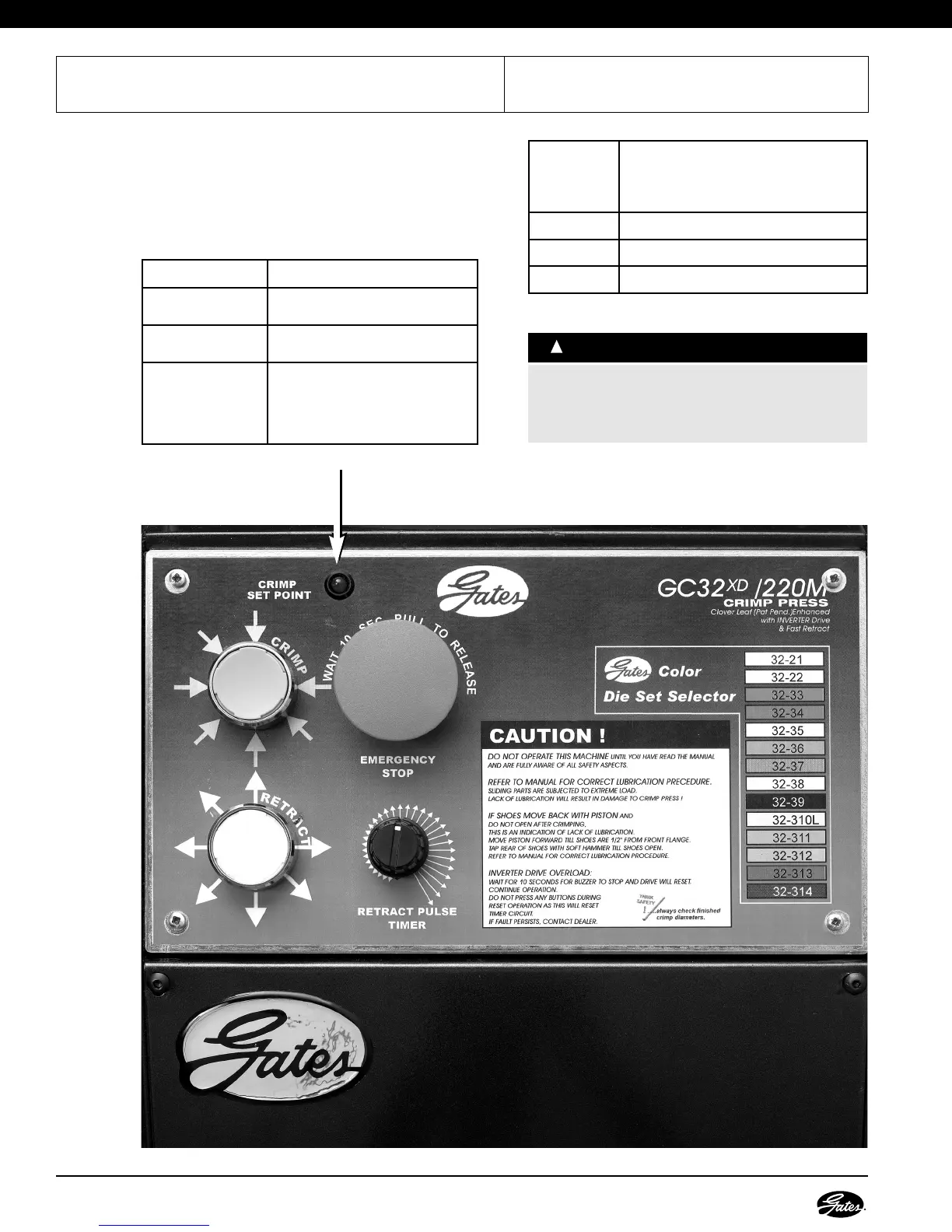

Red LED

on Control

Panel

Indicates

Flashing Crimper is ready

Solid Crimper is in the crimping process

Rapid Flashing Problem with electronics in control panel

PROBLEM CORRECTIONS

• Pump motor will

not start.

• Check electrical connections.

• Setting will not

change.

• Locking switch may be engaged.

Move Switch to left.

• Will not hold

crimp calibration.

• Flange head bolts are loose.

Check torque of flange bolts to

330 Nm or 2900 in lbs every 6

months of operation.

Loading...

Loading...