MC2000 USER GUIDE

7

Operating Principle

The kinematic crimping principle consists of transforming a rectilinear displacement, i.e.

that of the piston (8), into a radial displacement thus ensuring the crimping process by way

of the dies (7).

Mechanical bonding is achieved through the friction on a slope and a face on the barrel

clamp (3) and a slope (cone) on the piston (8) and the die holders (4). The die holders are

kept together during their travel by means of a spring arrangement.

The main components are made of a special steel and have been subjected to a series of

thermal body and surface treatments, so that they can resist the large loads and wear

through friction is prevented.

Precise guiding is ensured by means of two Teflon-Bronze bearers on the piston (14 & 17).

The piston is sealed by means of two O-rings + anti-extrusion bushes (15 & 16)

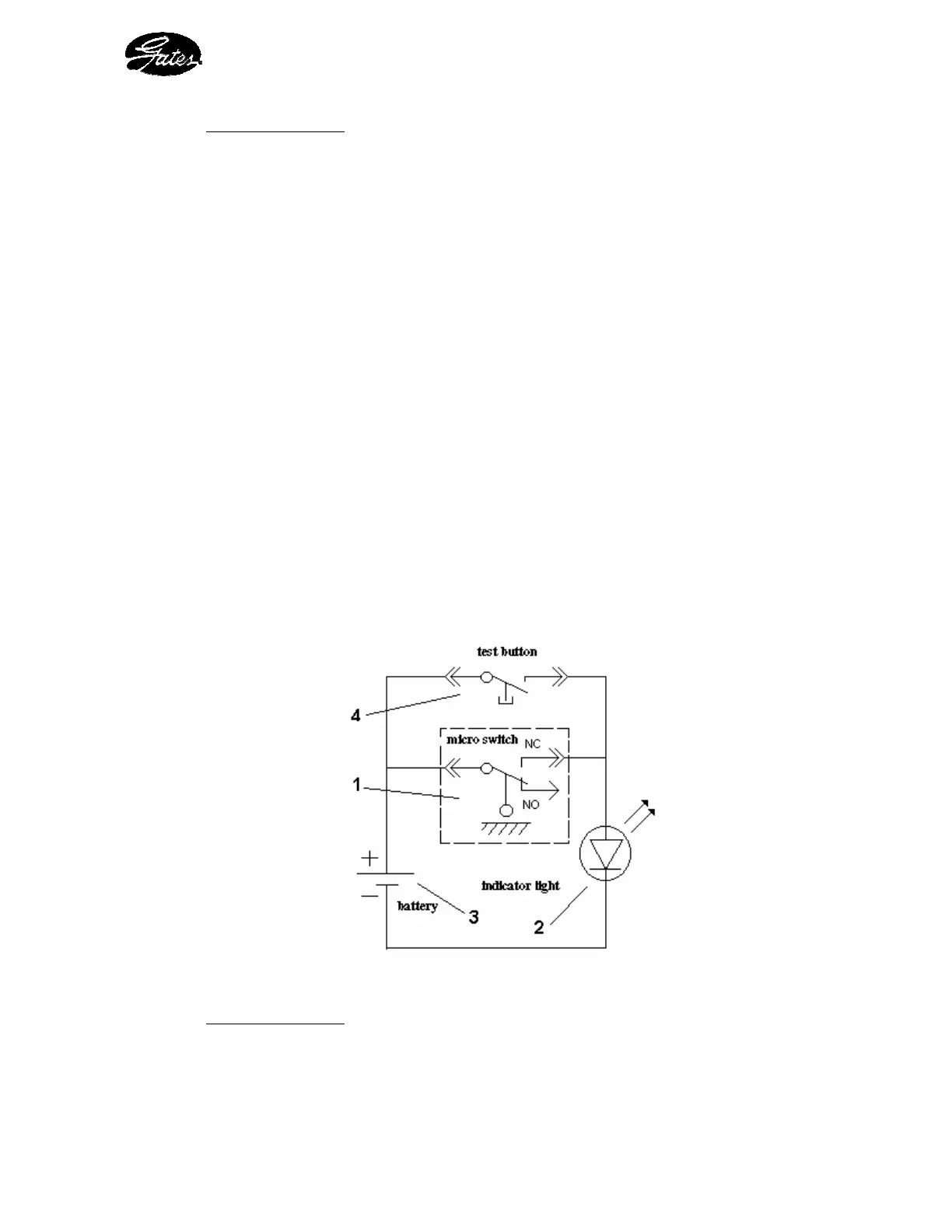

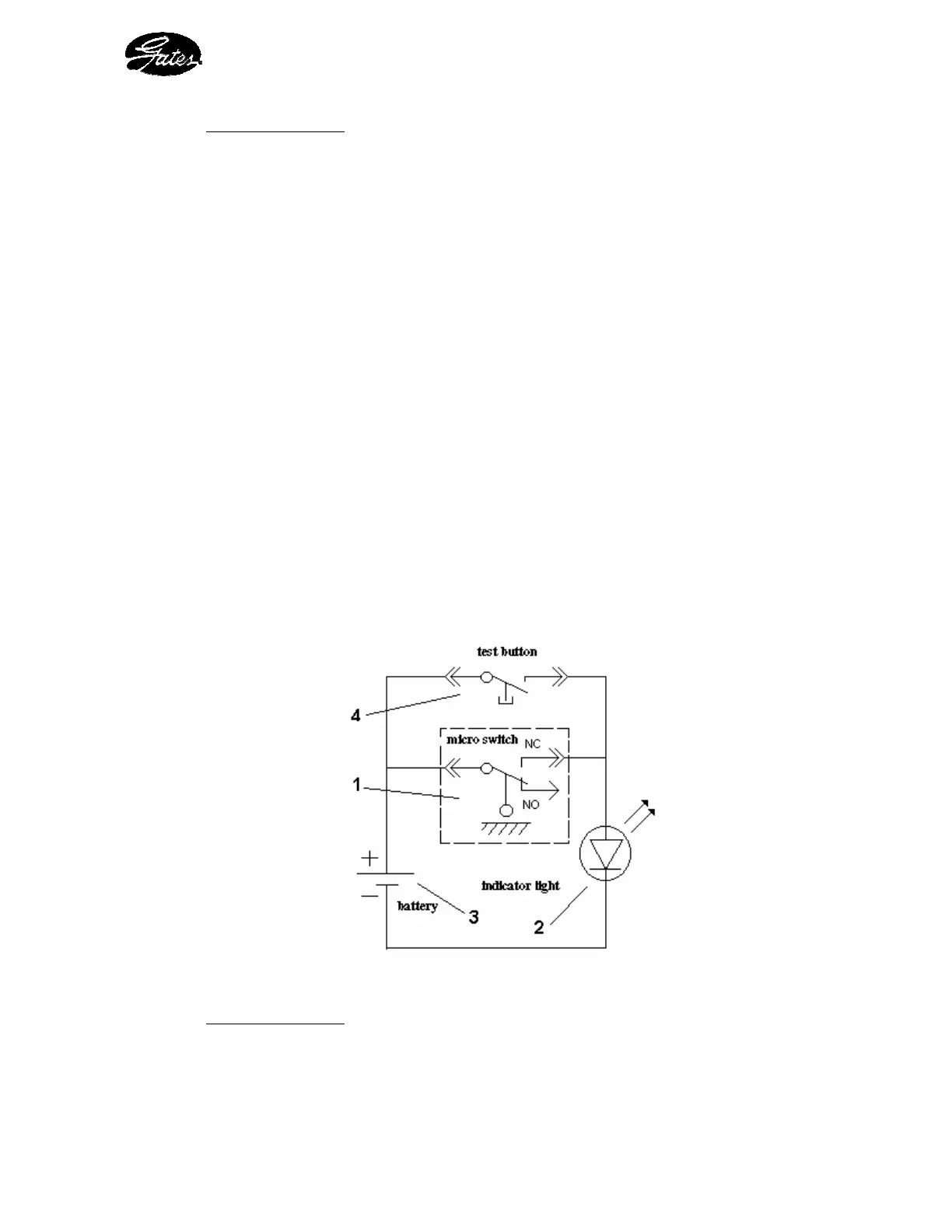

2. 3. 3 - THE ELECTRICAL SYSTEM

This system provides the supply power for the end-of-crimping indicator light

It comprises the following elements (see figure 3) :

- a micro-switch (1) - a 9V battery type 6 LR 61 (3)

- a red indicator light (2) - a test push-button (4)

Figure 3 : Electrical diagram

Operating Principle

This system indicates to the operator, by way of a light signal, that the set value on the

micrometer gauge has been reached, i.e. that the final crimping diameter has been attained.

Loading...

Loading...