CHAPTER 4: SETPOINTS MONITORING

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 4–291

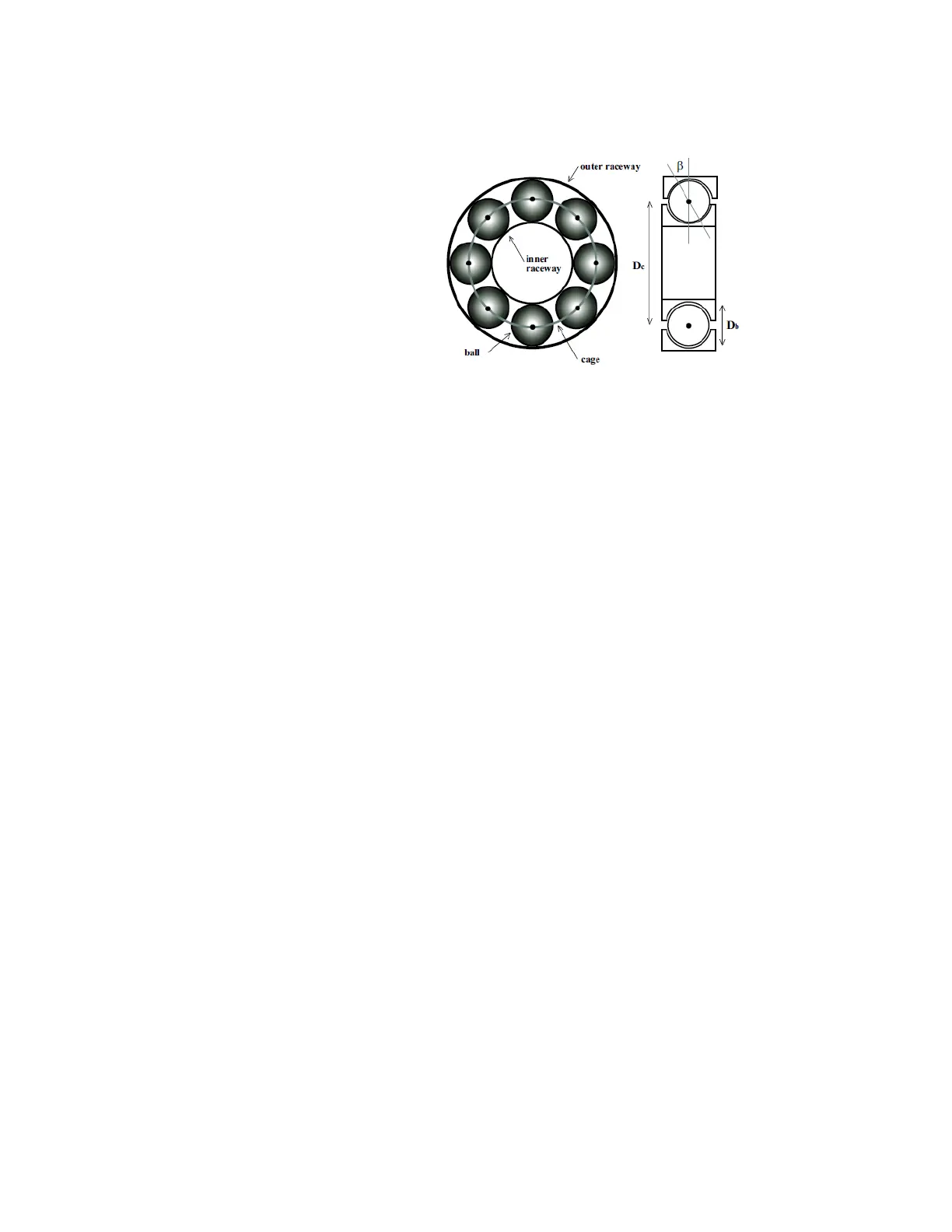

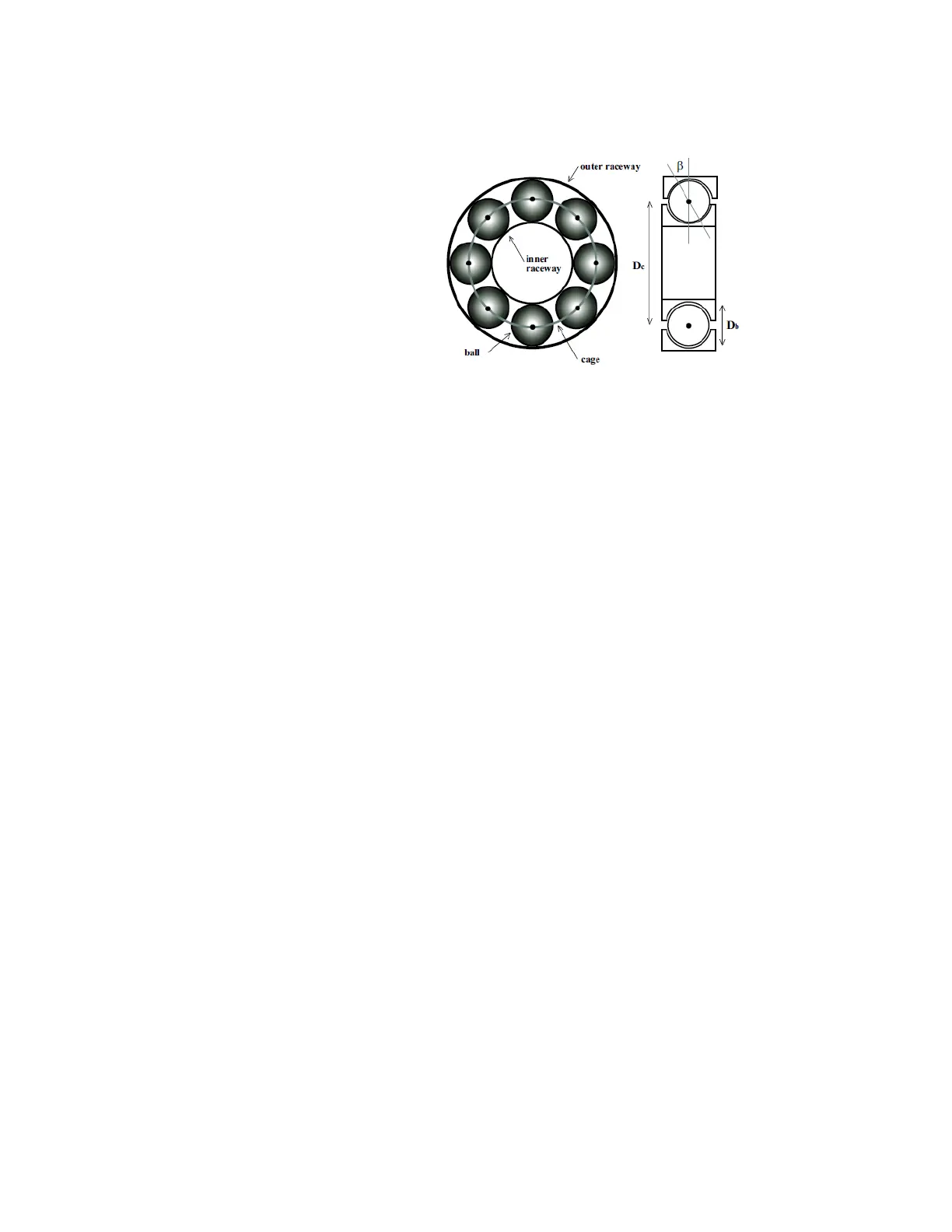

Figure 4-122: Ball bearing cross-sectional view

NO. OF STATOR SLOTS

Range: 1 to 500 in steps of 1

Default: 0

Configure the number of stator slots based on the motor design. This information is

available from the manufacturer or found in the motor technical manuals.

BEARING FAULT PKP STAGE 1(2)

Range: 1 to 100 dB in steps of 1 dB

Default: 10 dB (20 dB)

Configure the minimum dB level above the baseline dB level (for any load bin) at which

the bearing fault operand level 1 (level 2) picks up. This setting is applicable to both peak

magnitude and energy at peak magnitude.

BEARING FAULT PKP DELAY 1(2)

Range: 5 to 60 min in steps of 5 min

Default: 15 min

Configure the delay in minutes after which the bearing fault operand pickup level 1 (level

2) will operate if the level sustains.

MECH FAULT PKP STAGE 1(2)

Range: 1 to 100 dB in steps of 1 dB

Default: 10 dB (20 dB)

Configure the minimum dB level above the baseline dB level (for any load bin) at which

the bearing fault operand level 1 (level 2) picks up. This setting is applicable to both peak

magnitude and energy at peak magnitude.

MECH FAULT PKP DELAY 1(2)

Range: 5 to 60 min in steps of 5 min

Default: 15 min

Configure the delay in minutes after which the bearing fault operand pickup level 1 (level

2) will operate if the level sustains.

STATOR FAULT PKP STAGE 1(2)

Range: 1 to 100 dB in steps of 1 dB

Default: 10 dB (20 dB for stage 2)

Configure the minimum dB level above the baseline dB level (for any load bin) at which

the bearing fault operand level 1 (level 2) picks up. This setting is applicable to both peak

magnitude and energy at peak magnitude.

Loading...

Loading...