48 EVOLUTION SERIES E9000 MOTOR CONTROL CENTER

Electronic overload for circuit breaker and

fused controllers

The tripping current is 120% of the dial setting.

For continuous-rated motors with a service factor

of 1.15 to 1.25, set the dial to the motor full-load

current. For continuous-rated motors with a

service factor of 1.0, set the dial to 0.9 of the motor

before energizing.

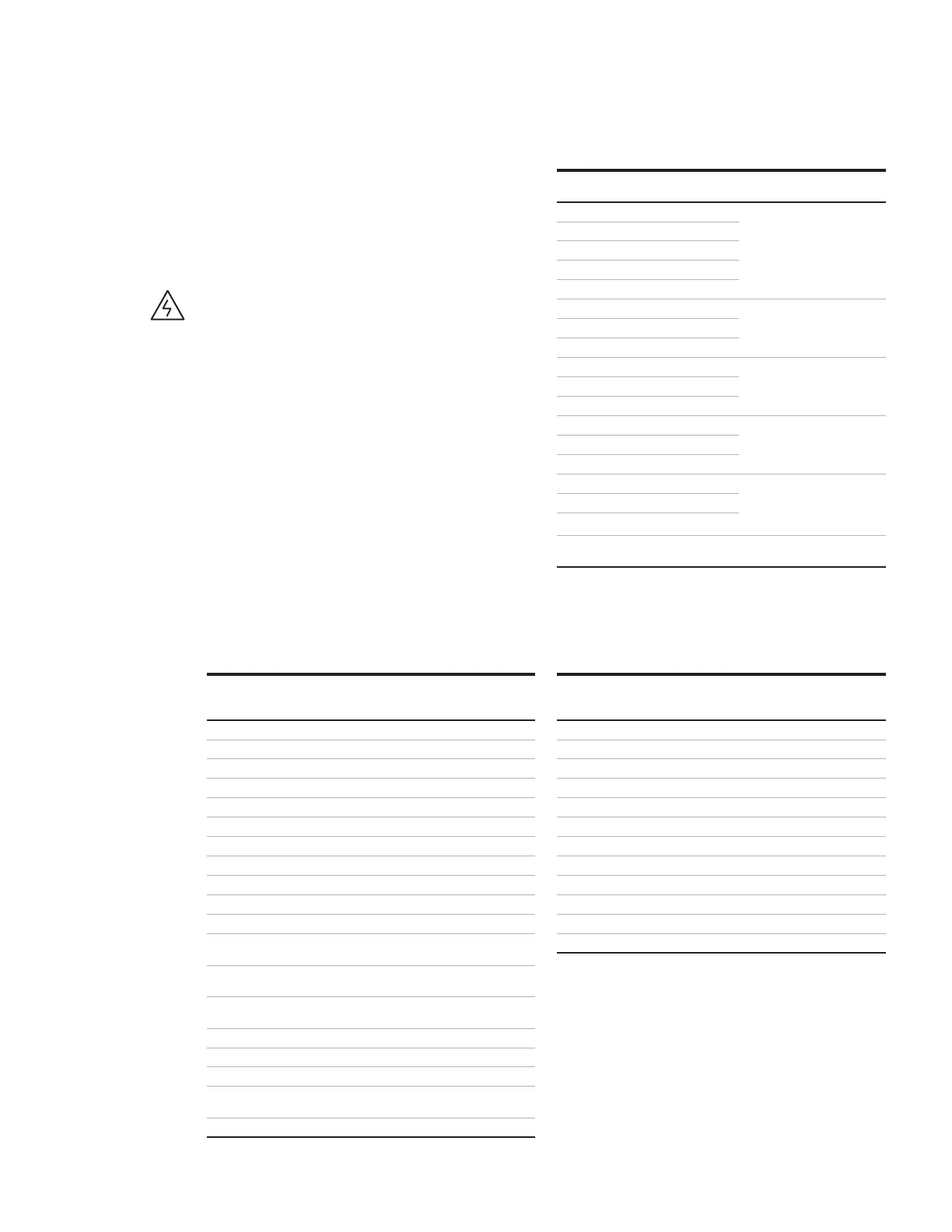

Catalog numbers of electronic overloads

for various sizes of NEMA starters and

current ranges

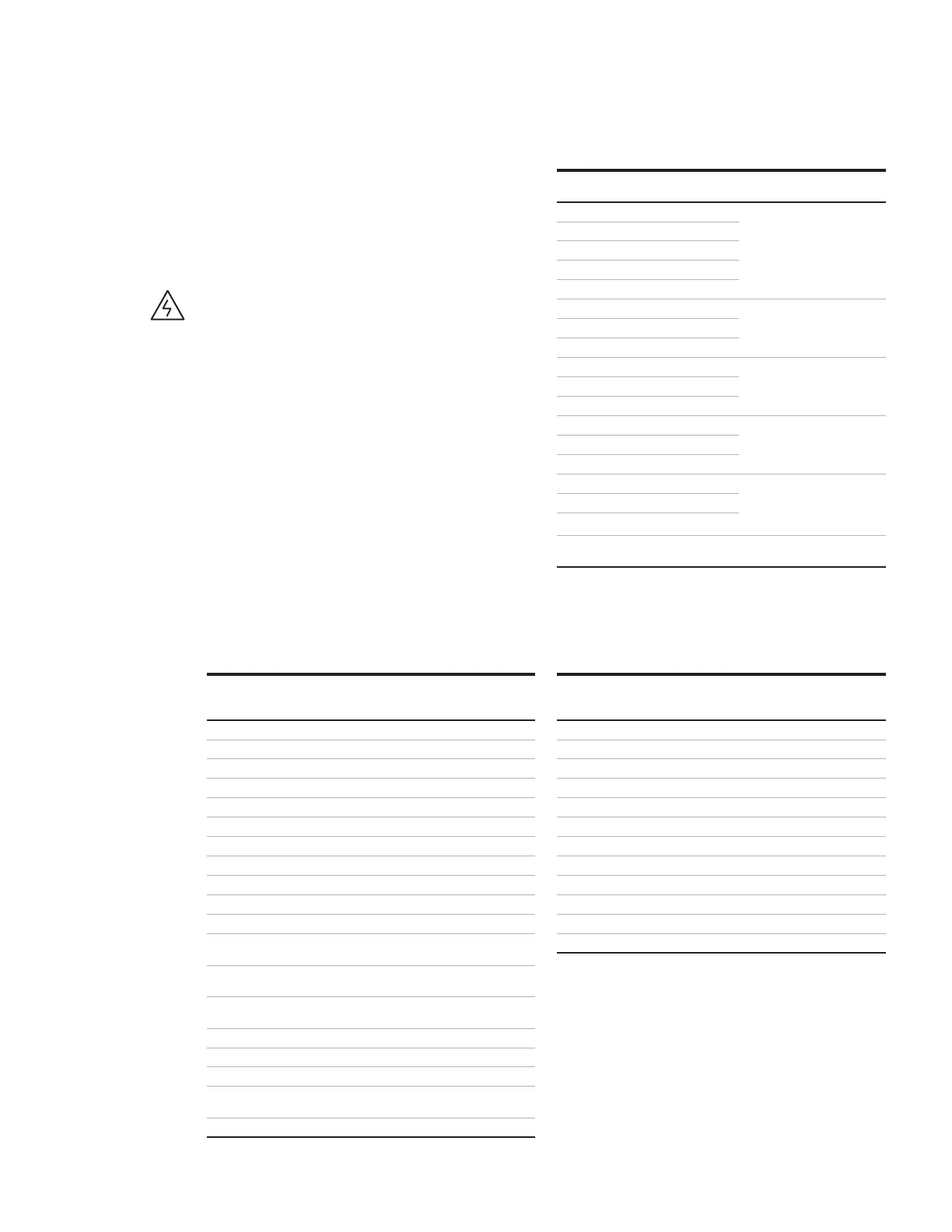

IEC style overload relays

C2000 contactor CLNCJ type RT overload relay

for 1/2X starter

Provide short-circuit protection in accordance with

NEC Article 430 or CE Code Part 1.

Tripping current is 120% of Dial setting. Motors

with 1.15-1.25 service factor, set dial to motor

FLA Motors with 1.0 service factor, set dial

to 0.9 motor FLA.

Catalog numbers of electronic overloads

for various sizes of NEMA starters and

current ranges.

NEMA

Size

FLA

Range in

Amps

Catalog

Number Breaker Frame and Type

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

E Mag. and Thermal Mag.

Thermal Mag.

Thermal Mag.

Thermal Mag.

Thermal Mag.

Current

Range

Max

CB

Cat.

No.

Class Cat.

No.

Class Lug/

Wire

Size

Torque

(in-lbs)

RTNIL

RTNIM

RTNIN

RTNIP

RTNIS

RTNIT

NEMA

Size

FLA Range

in Amps

Catalog

Number Max. Fuse in Amps

Time-Delay

Class RandJ

Time-Delay

5¹

6²

Class L

Opening of the branch-circuit protective device

may be an indication that a fault current has been

interrupted. To provide continued protection

against £re or shock hazard, examine all current-

carrying parts and other components of the motor

controller and replace any damaged components. If

heater burnout occurs, the complete overload relay

must be replaced.

Loading...

Loading...