Control Handle

OFF

■ Shuts off water.

FILTER

■ For filtered water. Directs water flow

through filter.

BYPASS

■ Permits flow of water to the house without flowing through the filter.

Use this position for filter changes or if filtered water is not desired

.

2

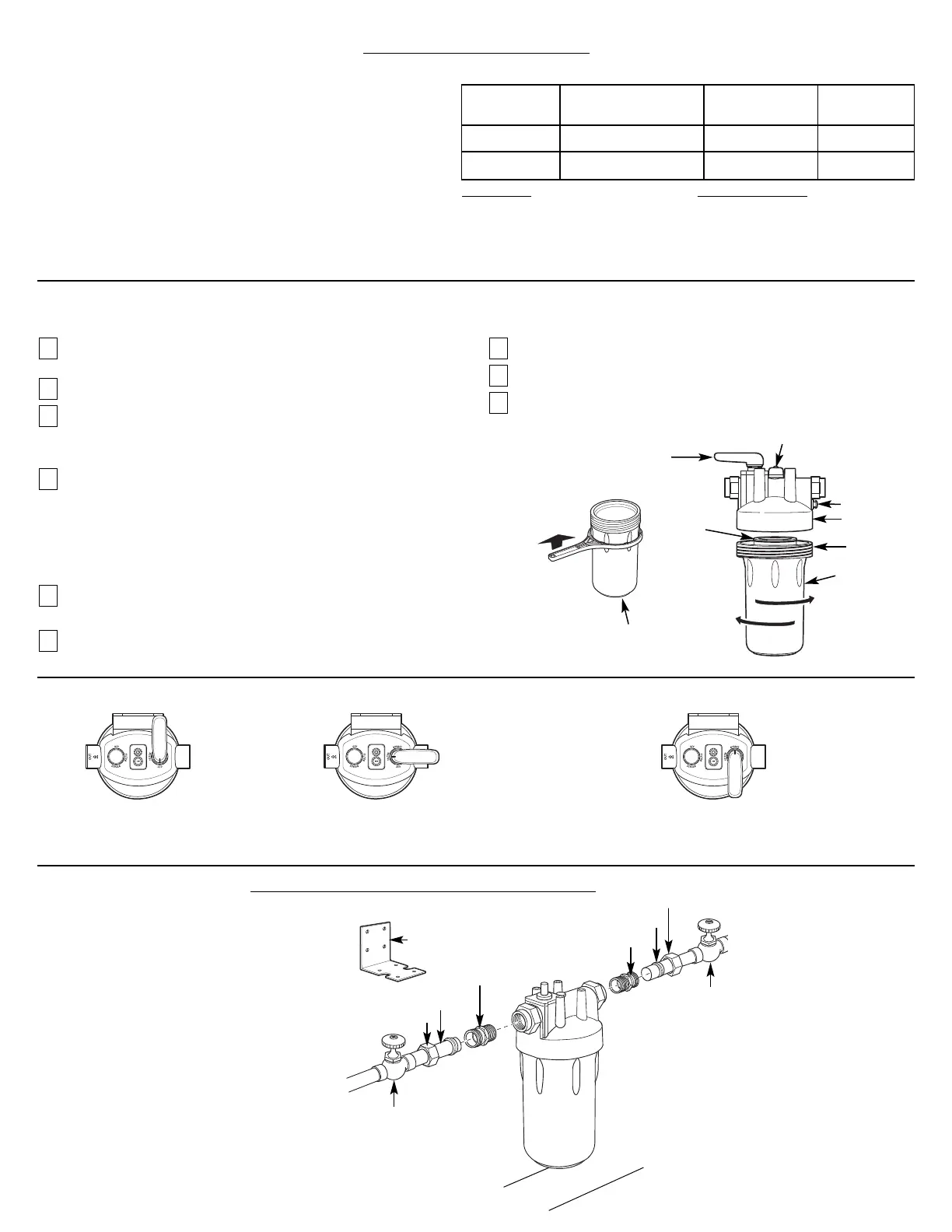

Filter Cartridge Replacement

You should change your filter when the water flow is noticeably reduced or at least every 3 months.

Turn off water to filter. Rotate the control handle to the

BYPASS or OFF position (see

Valve Operations

section).

Press the red pressure-release button to release pressure.

Unscrew the filter canister and discard used filter. Wash the

filter canister with mild soap and water.

Do not

use harsh

cleaners or hot water.

Inspect the filter canister O-ring. Make sure it is lightly

lubricated with clean food-grade silicone grease (silicone

grease is available through GE Parts and Service:

1.800.626.2002, part number WS60S10005). Be sure the

O-ring is seated in the groove. It is recommended that you

replace the O-ring if it is damaged.

Place a new filter cartridge into the canister, making sure it

is centered and completely seated on the bottom seal.

Reinstall the filter canister to the unit. Use the canister

wrench to tighten the canister. DO NOT OVERTIGHTEN.

Slowly rotate the control handle to the FILTER position.

Press the red pressure-release button to remove trapped air.

After installation, open any downstream faucet and flush the

cartridge for 15 minutes, wait one hour, then flush again for

15 minutes before using the water.

9

8

7

6

5

4

3

2

1

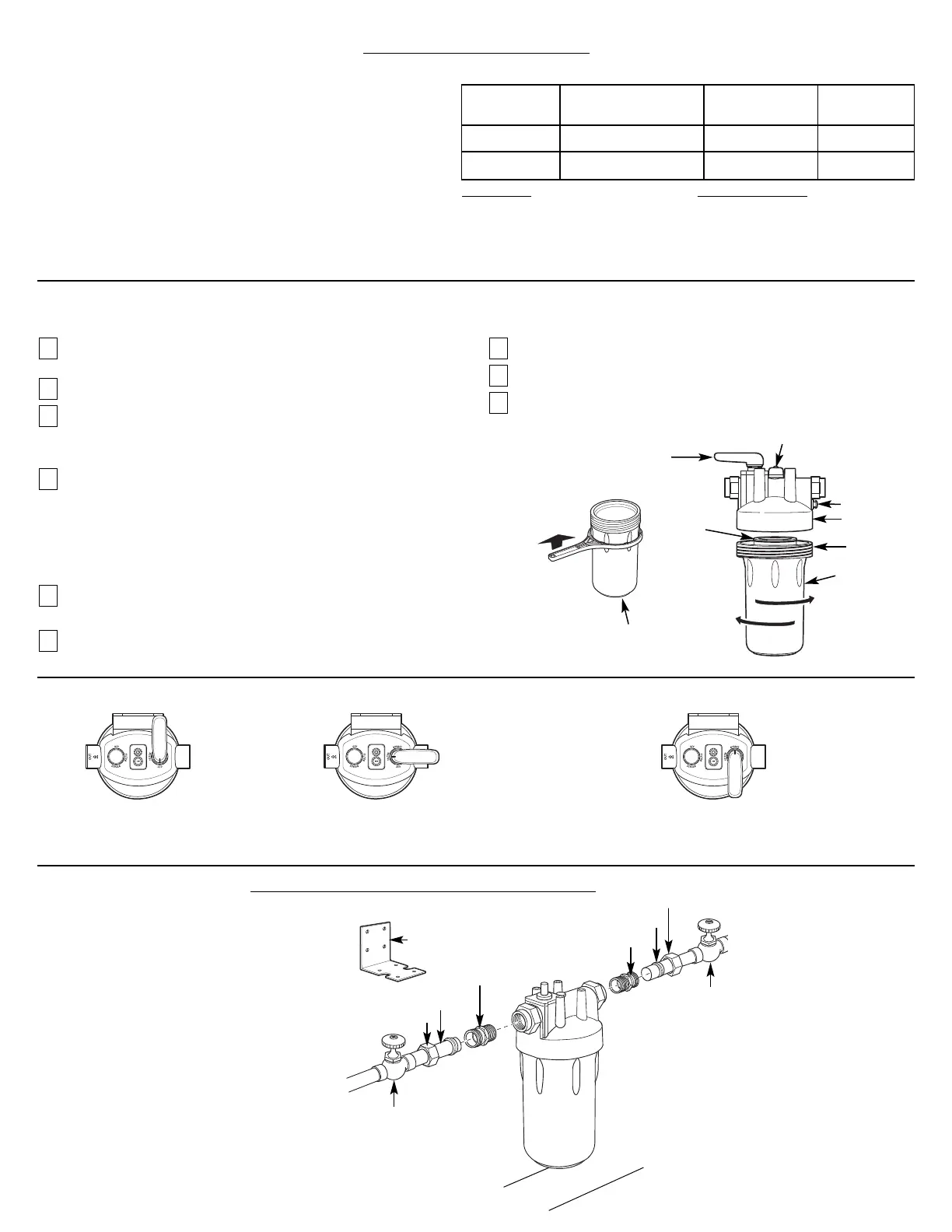

Installation Overview

NOTE: Be sure to allow a minimum space

of 1

1

⁄

2

″

–2

″

under the filter for removing

the sump to change the cartridge.

Turn canister wrench

clockwise to remove

Canister

Turn

clockwise

to remove

canister

Turn

counterclockwise

to tighten

Red pressure-

release button

Filter

cartridge

O-ring seal

Filter canister

Head

STEP-BY-STEP INSTALLATION INSTRUCTIONS

Recommended

shut-off valve

Recommended

shut-off valve

Fitting

Ferrule

Hex nut

Fitting

Ferrule

Hex nut

1

1

⁄2 ″–2″

Typical installation

Remote timer

Mounting

bracket

CARTRIDGE SPECIFICATIONS

Influent Challenge Reduction Average

Substance Concentration Requirements Reduction

Standard 42

Chlorine 2.0 mg/L ± 10% ≥ 50% 87.8%

Performance Data

This system has been tested according to NSF/ANSI 42

for the reduction of the substances listed at right. The

concentration of the indicated substances in water

entering the system was reduced to a concentration

less than or equal to the permissible limit for water

leaving the system, as specified in NSF/ANSI 42.

FXHTC Cartridge

Test Conditions

Flow Rate: 3 gpm (11.4 Lpm)

pH: 7.5± 1

Inlet Pressure: 60 PSI (4.1 bar)

Temperature: 68°F ± 5°F (19.8°C ± 2.5°C)

Operating Requirements

Pressure: 30–100 PSI (2.1–6.9 bar)

Turbidity: 5 NTU Max.

Temperature: 40°F–100°F (4.4°C–37.7°C)

Capacity: 30,000 gallons (113,562L) or 3 months

Testing was performed under standard laboratory conditions; actual performance may vary.

Control handle

Loading...

Loading...