SYSTEM PERFORMANCE 7

Rev C

System Pressure Drop

Estimating system pressure drop is the second step in determining net

driving pressure. Pressure drops are created by:

• Tubing friction losses

• Obstructions

• Elevation differences

•Post Filter

•Faucet

• Osmonic pressure

Pressure Drop Through Tubing

The Merlin system uses polyethylene tubing to carry the permeate water.

All tubing creates a pressure drop when water passes through it. This

pressure drop is created by friction within the flowing fluid and is a

function of the flow rate through the tubing and the tubing length. To

simplify this explanation, changes in water density because of

temperature, which does affect tubing pressure drop, have been ignored.

The farther the permeate travels through the tubing, the greater the

pressure drop.

To estimate pressure drop through tubing follow the steps below:

1. Estimate flow rate into the tubing using Table 1.

Use inlet pressure into the Merlin as the Net Driving Pressure for

the purposes of this estimation. By using inlet pressure as the Net

Driving Pressure in Table 1, flow directly from the Merlin without

any pressure drop is found.

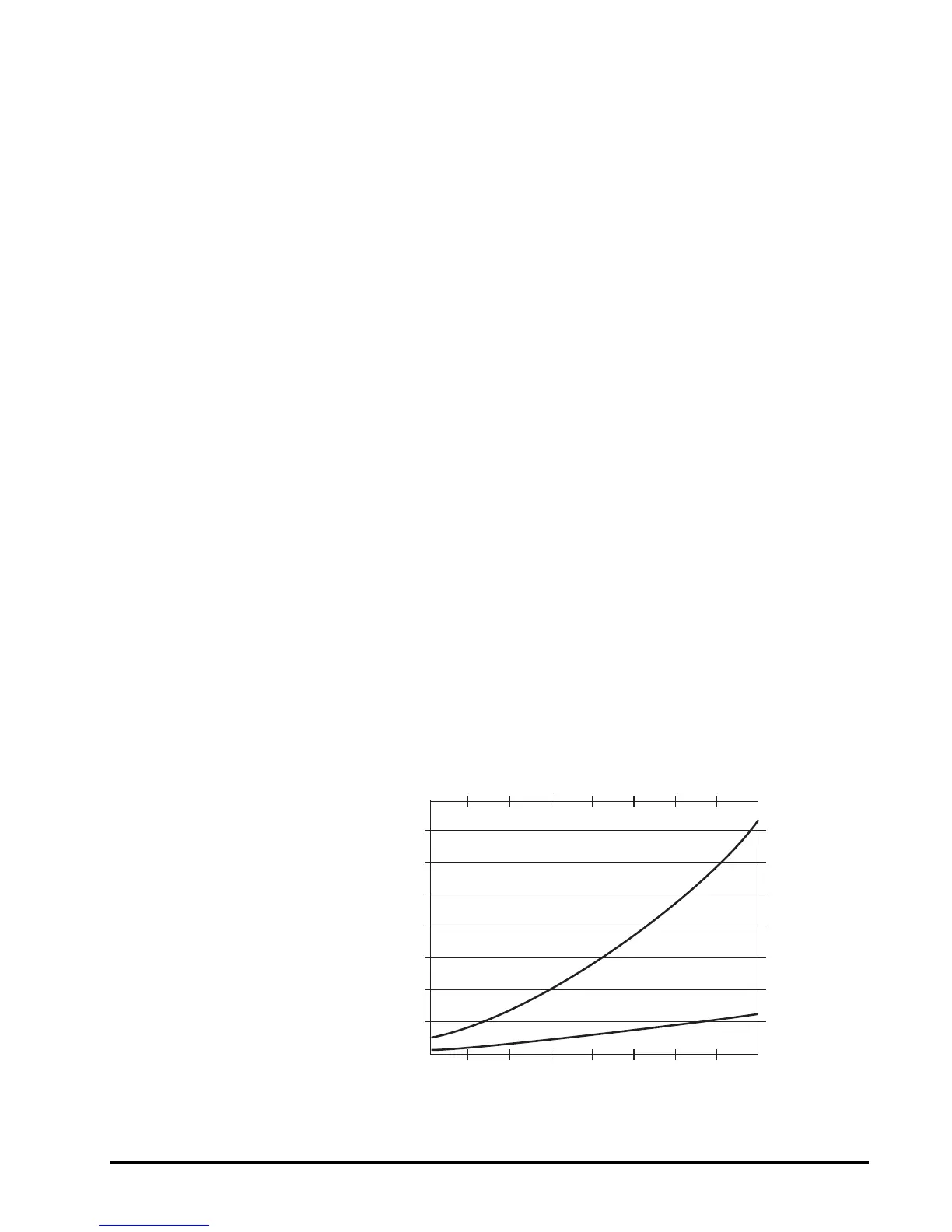

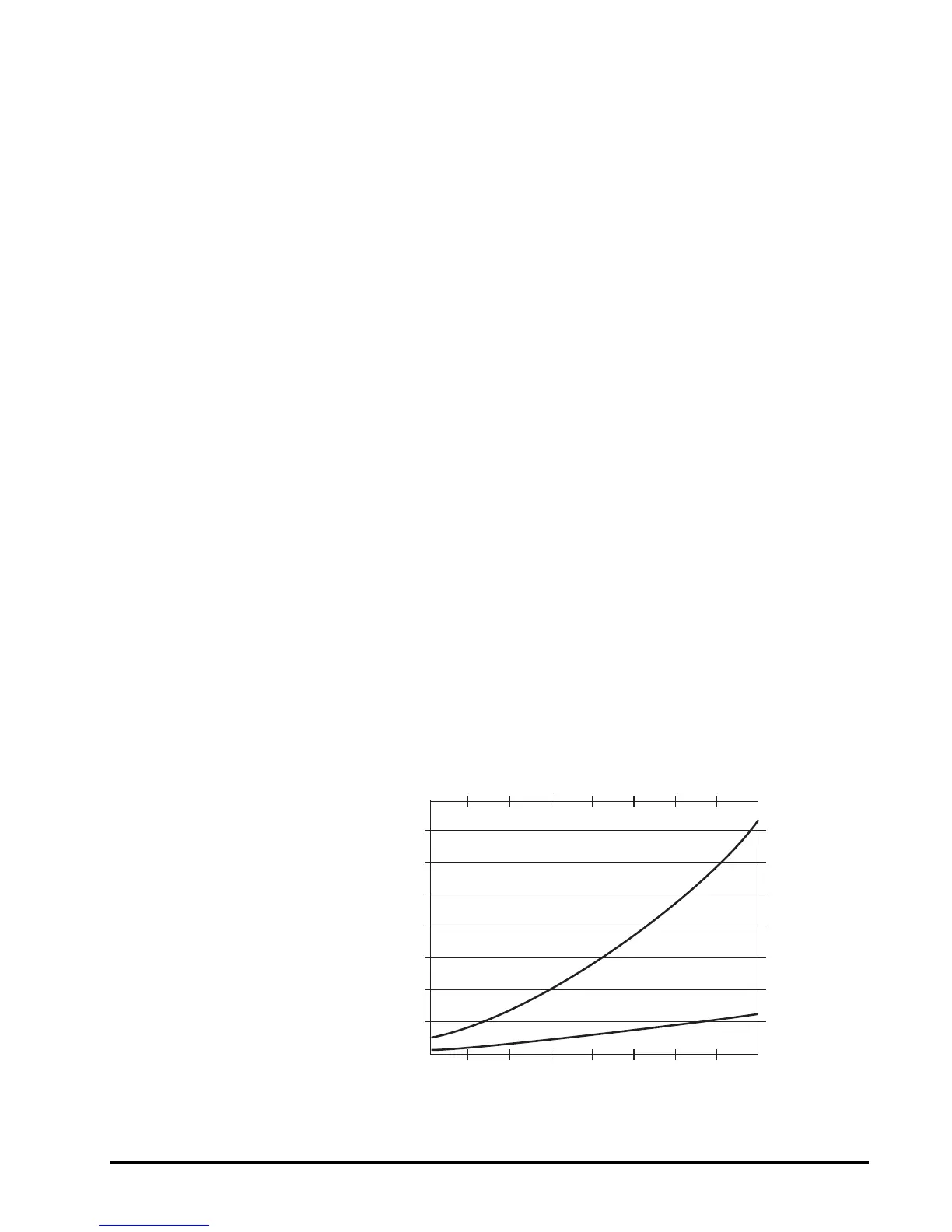

2. Using the estimated flow rate found in step 1 above, find the pressure

drop through the tubing with Figure 4.

Figure 4

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0

Inlet Flow Rate

m

Pressure Drop / ft. Tubing (psi)

1/2" Tubing

3/8" Tubing

.027

.024

.020

.017

.013

.010

.006

.003

0

.75 1.13 1.51 1.89 2.29 2.65 3.03 3.41 3.78

Inlet Flow Rate (Lpm)

Pressure Drop / .304 m Tubing (bar)

Estimated Tubing Pressure Drop For Water Between 40 - 100˚F (4.4-37.8˚C)

Loading...

Loading...