Do you have a question about the GEA VARIVENT N and is the answer not in the manual?

Details manual content, illustrations, and symbols.

GEA Tuchenhagen GmbH's address and contact information.

Compliance statement for EC Machinery Directive 2006/42/EC.

Proper application, operational prerequisites, and directive compliance.

Responsibilities for safe operation and monitoring of the component.

Guidelines for safe operation, environmental protection, electrical safety, and residual dangers.

Personnel training requirements, safety equipment, and danger zone awareness.

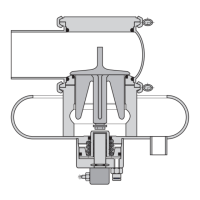

Overview of the valve's physical structure and labeled parts.

Explanation of how Valve N and Valve U operate and their status indicators.

Key identification data provided on the valve's type plate.

Technical details including size, materials, and fitting position.

Operating temperature limits and compressed air supply requirements.

Chemical and temperature resistance data for various sealing materials.

Safety precautions and general notes for installing the valve correctly.

Procedure for fitting valves with detachable connection elements.

Welding procedure for installing valve housings into pipe systems.

Guidelines for connecting pneumatic hoses and electrical components to the control top.

Essential safety rules and principles for carrying out maintenance and repair.

Procedures for valve inspections and recommended maintenance schedules based on usage.

Step-by-step guides for dismantling and reassembling valve types N and U.

Methods for cleaning valve parts and replacing wear items like O-rings and V-rings.

Detailed list of components and part numbers for valve type N.

Detailed list of components and part numbers for valve type U.

Detailed list of components and part numbers for valve type U_R.

Technical drawings and dimensional data for valve type N.

Technical drawings and dimensional data for valve type U.

Technical drawings and dimensional data for valve type U_R.

Glossary of technical terms and abbreviations used in the manual.

| Type | Control Unit |

|---|---|

| Model | GEA VARIVENT N |

| Material | Stainless steel (typically AISI 316L) |

| Hygienic Design | Designed for CIP/SIP cleaning |

| Certification | EHEDG certified |