Do you have a question about the GEA VARIVENT DN 25 and is the answer not in the manual?

Details about operating instructions, symbols, and illustrations.

Provides manufacturer address and contact details for inquiries.

Official declarations regarding compliance with EC directives.

Defines proper use, requirements, and directives for safe operation.

Outlines responsibilities of the operating company for safe handling.

Principles for safe operation, environmental, and electrical safety.

Specifies required qualifications and safety signage for personnel.

Identifies potential dangers and defines specific hazard zones around the valve.

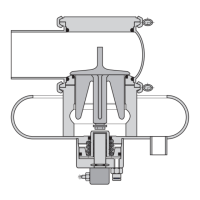

Illustrates the physical components of the valve with part numbers.

Explains the operating principles of shut-off, cleaning, and actuator functions.

Guidelines for storing valves and parts to prevent damage.

Instructions for safe handling and lifting during transportation.

Procedures for verifying the completeness and condition of delivered equipment.

Details found on the valve's identification plate.

Key technical data for the valve and operating temperatures.

Specifications for compressed air used in the valve's operation.

Compatibility of sealing materials with media and temperatures.

Tables for pipe sizes and required tools for installation.

Recommended lubricants and weight specifications for valve components.

General safety precautions for installing the valve and its components.

Specific instructions for valve positioning and system preparation.

Details on air requirements and hose connection procedures.

Instructions for connecting the electrical components of the control top.

Steps and safety measures for initial setup and commissioning.

Pre-commissioning checks and observations required for smooth operation.

Rules and principles for safe monitoring and operation of the valve.

Guidelines and examples for cleaning the valve and its parts.

Specific method for cleaning the leakage cavity within the valve.

Procedure for passivation, typically done before plant commissioning.

Safety rules for maintenance, repair, and disassembly.

Regular checks for seals, connections, signs, and recommended maintenance intervals.

Detailed instructions for dismantling the valve and its components.

Procedures for installing and assembling the valve from individual parts.

Procedures for checking valve strokes, adjusting feedback, and replacing seals.

Instructions for applying lubricant to threads and seals for proper function.

Table listing common faults, their causes, and solutions.

Steps for safely shutting down the valve and securing it.

Guidelines for proper disposal of the valve and its components.

Diagrams identifying various parts of the valve with reference numbers.

Table detailing dimensions and weights for different valve sizes and pipe connections.

Glossary of technical abbreviations and terms used in the manual.

| Brand | GEA |

|---|---|

| Model | VARIVENT DN 25 |

| Category | Control Unit |

| Language | English |