Maintenance

Owner’s Manual for Stationary Industrial Generators 23

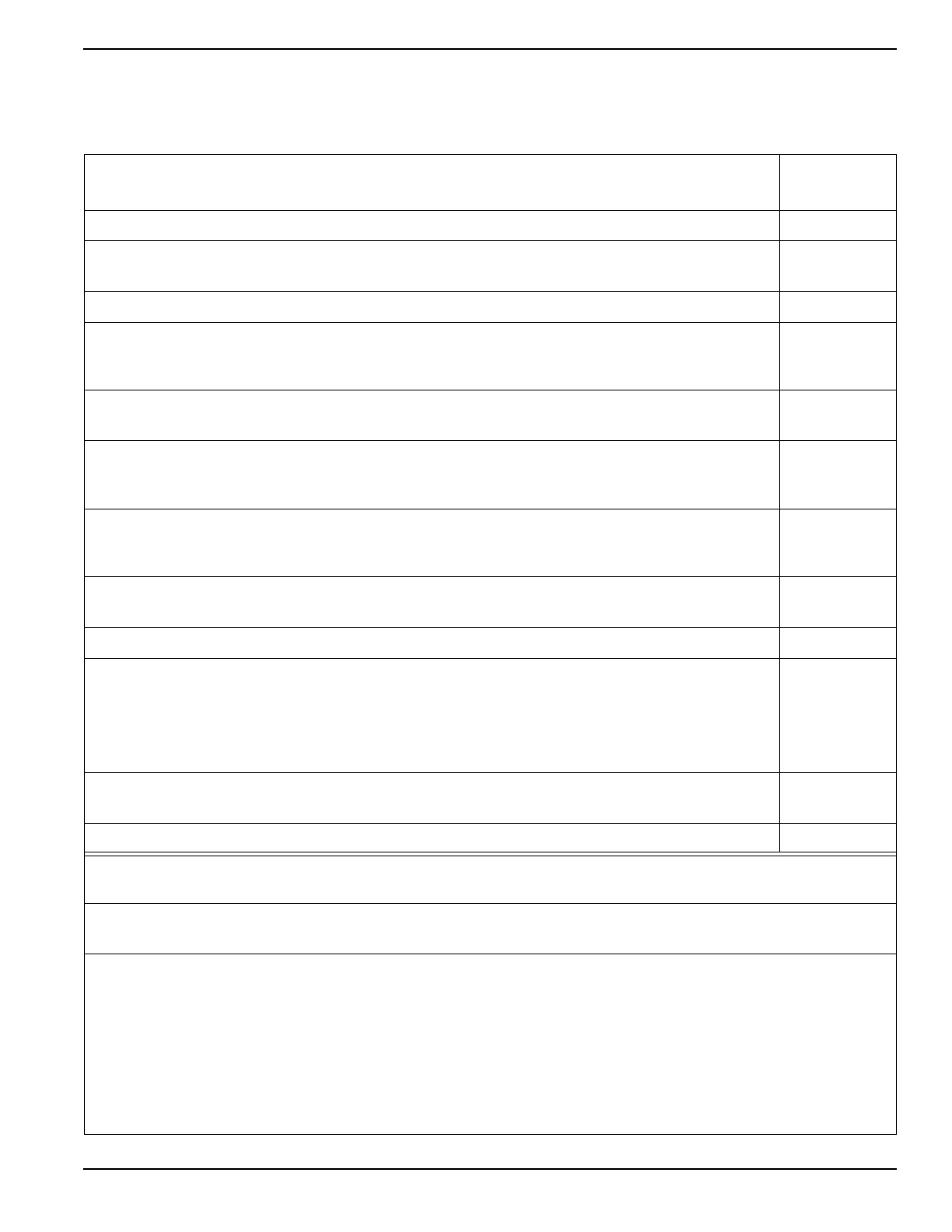

4.4 — Maintenance Level 1 - Monthly

These maintenance tasks can be performed by a trained authorized operator. Comply with all safety notices contained

in the Owner’s Manual.

Authorized Operator Maintenance Tasks

Requires approximately 0.5 hours per unit.

Task Completed

Date/Initials

1.

Disable the unit from operating per the instructions in the owner’s manual.

2. Check the engine oil level. The level should be between the low and full markings on the

dipstick. Adjust as necessary.

3. Gearbox Equipped Only: Check the gearbox oil level. Adjust as necessary.

4. Check the engine coolant level. Make sure the level in the coolant catch tank is between the

cold and hot level markings. Adjust as necessary. Use only a 50/50 mixture of appropriate

coolant.

5. Check the battery electrolyte level (if accessible). Adjust as necessary (add only distilled or

deionized water to replenish battery cells).

6. Check the battery terminal posts, connections, cables and charger connections, and battery

hold-downs for signs of corrosion, looseness, etc. Remove, clean and tighten connections as

necessary.

7. Check operation and condition of the battery charger. Check operation and condition of

optional block heater, oil sump heater, and battery warmer (if equipped). Correct discrepancies

as necessary.

8. Check the air inlets and outlets (enclosure or building vents) for debris or blockage. Correct as

necessary.

9. Visually inspect the fuel supply system for signs of leaks or damage. Correct as necessary.

10. Perform a 5 minute, no-load operational test of the unit. Check unit voltage and frequency.

Visually inspect the unit for leaks, wear, damage, loose connections or components, and

corrosion. Correct as necessary.

Voltage: Frequency:

11. If the control has alarm and/or event or run logs, record the alarm and event logs to a history

file for the unit.

12. Return the unit to operational condition.

Date inspection Completed: Unit hour Meter Reading:

Technician/Authorized Operator Signature signifying inspection complete:

Record any oil or coolant added and notes about any discrepancies found and corrective action taken.

Loading...

Loading...