Elite Steam +030222075 Rev. 3.5 – July 2012

3.3 Plumbing

3.3.1 Water Characteristic Requirements

The humidifier must be supplied with water with the following characteristics:

• pressure between 20psi and 110psi or 0.1 and 0.8 MPa (1 and 8 bar)

• temperature between 33°F and 104°F or 1°C and 40°C

• flow-rate minimum of 0.45 L/min or 0.21gpm

• hardness no greater than 40°fH (equal to 400 ppm³ of CaCO), conductivity: from 125 to 1250 μS/cm

• absence of organic compounds

• the characteristics of the water of supply must fall within the following limits:

LIMIT VALUES FOR LOW SALT CONTENT WATER LIMIT VALUES FOR LOW NORMAL WATER

Specific conductivity (R,20°C)

Specific conductivity (R,20°C)

Total dissolved solids (c R)

Total dissolved solids (c R)

Tab.3.d Tab.3.e

(*) Values dependent on the specific conductivity: in general: cR~=0.65*σR, 20°C; R180~=0.9*σR, 20°C

Note: There is no relationship between the hardness and conductivity of water.

Water Conductivity must be matched by specifications of the steam cylinder. Check or know the water conductivity of

the proposed site before installation. Replace the steam cylinder before startup if not correct. See Table 3.f right.

DS25, RS25, DS25LC, RS25LC, DS35, RS35

DS25, RS25, DS25LC, RS25LC, DS35, RS35

Tab.3.f

The following water types are not acceptable:

1. Softened water as this will lead to foam, electrode corrosion and greatly shortened

cylinder life.

2. Water containing disinfectants or corrosion inhibiters, as these are potential irritants.

3. Industrial water, boiler water or water from cooling circuits.

4. Any potentially chemically or bacteriologically contaminated water.

5. Heated water.

3.3.2 Water Supply Connection

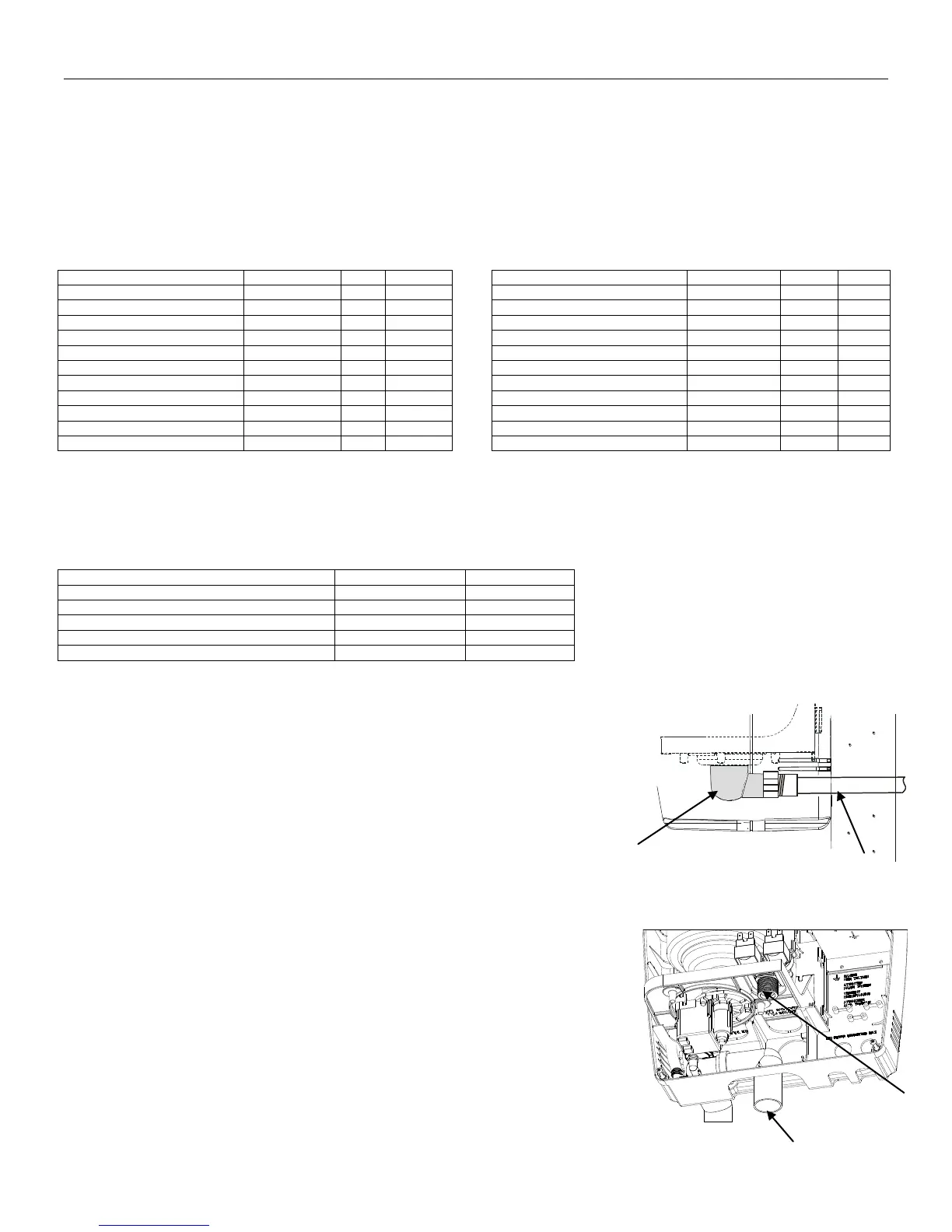

We recommend the connection between the fill valve and the water supply line by a

soft poly hose capable of absorbing the water hammering in order to avoid damage to

the fill valve itself. The water line may be routed through the back or through the

bottom of the unit. With poly tubing, a tubing support must be used to prevent tubing

collapse and leaks. The fitting then threads onto the fill valve inlet located on the

bottom of the humidifier using a 3/4” G connection. Note that there is a strainer built

into the fill valve fitting underneath the unit, which will require periodic

cleaning, so be sure to allow clearance for access.

Loading...

Loading...