9

English

UNPACKING AND CONTENTS

IMPORTANT: Due to modern mass production techniques, it is unlikely the tool

is faulty or that a part is missing. If you find anything wrong, do not operate the tool

until the parts have been replaced or the fault has been rectified. Failure to do so could

result in serious personal injury.

CONTENTS IN PACKAGE

Description Q'ty Description Q'ty

ASSEMBLY AND ADJUSTMENTS

WARNING: Always be sure that the tool is

switched off and unplugged before adjusting, adding

accessories, or checking a function on the tool.

WARNING: 3-1/2” is the maximum blade

diameter for your saw. Never use a blade that is too

thick to allow the outer flange washer to fit properly

on the spindle. Using a blade that is too thick will

prevent the blade bolt from securing the blade on

the spindle. Larger diameter blades will contact

the blade guards. Either situation could result in a

serious accident.

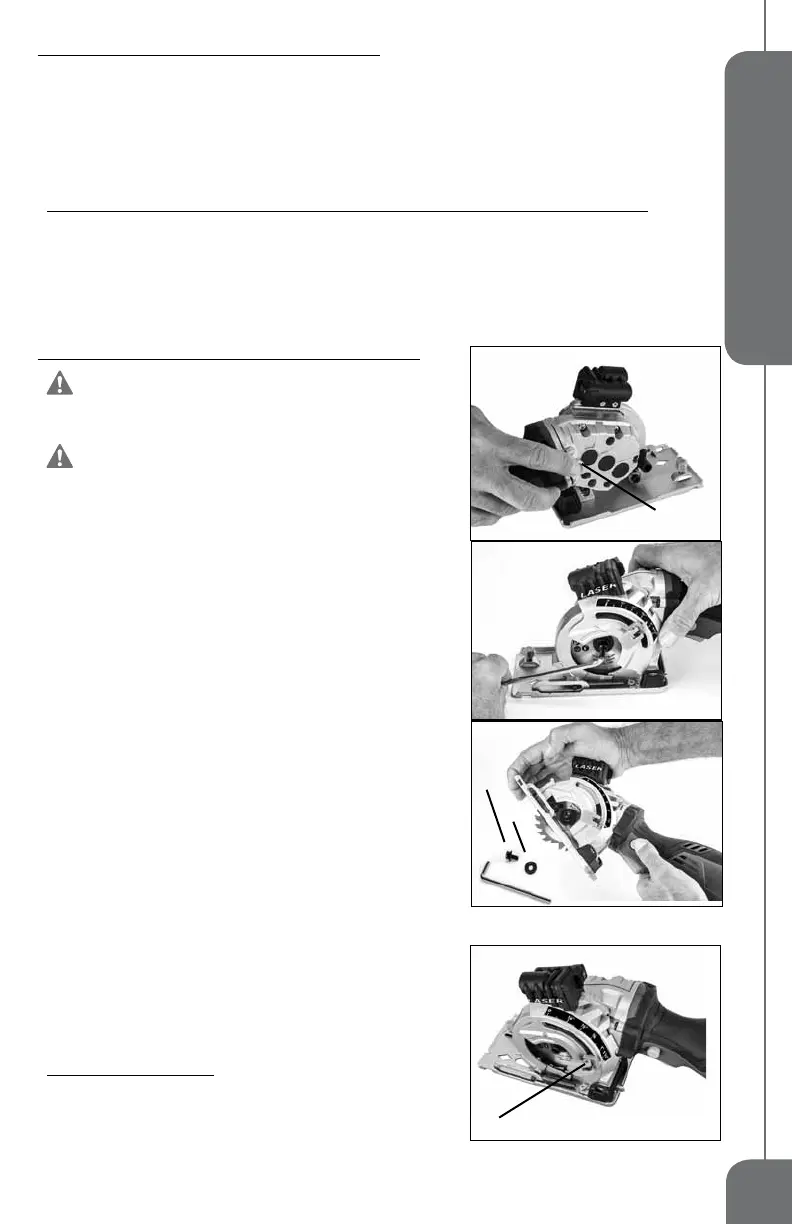

CHANGING BLADES (FIG 2, 3, 4)

1. Unplug the tool from the power source.

2. Press and hold the spindle lock (14), release the clamping screw

(12) by using the Allen key provided (turn clockwise to loosen).

Remove the clamping screw, and outer flange (31).

3. Set the cutting depth to the maximum. (See “Setting the Cutting

Depth” section)

4. Press down the lock-off / plunge release button (1) to lift up the

base plate.

5. Lift blade up off spindle then pull from the tool to remove blade.

6. The installation of a saw blade is done in the reverse order.

7. Press the spindle lock button (until it engages) and tighten the

clamping screw firmly.

NOTE: The arrow on the saw blade must match the arrow

showing direction of rotation on the guard.

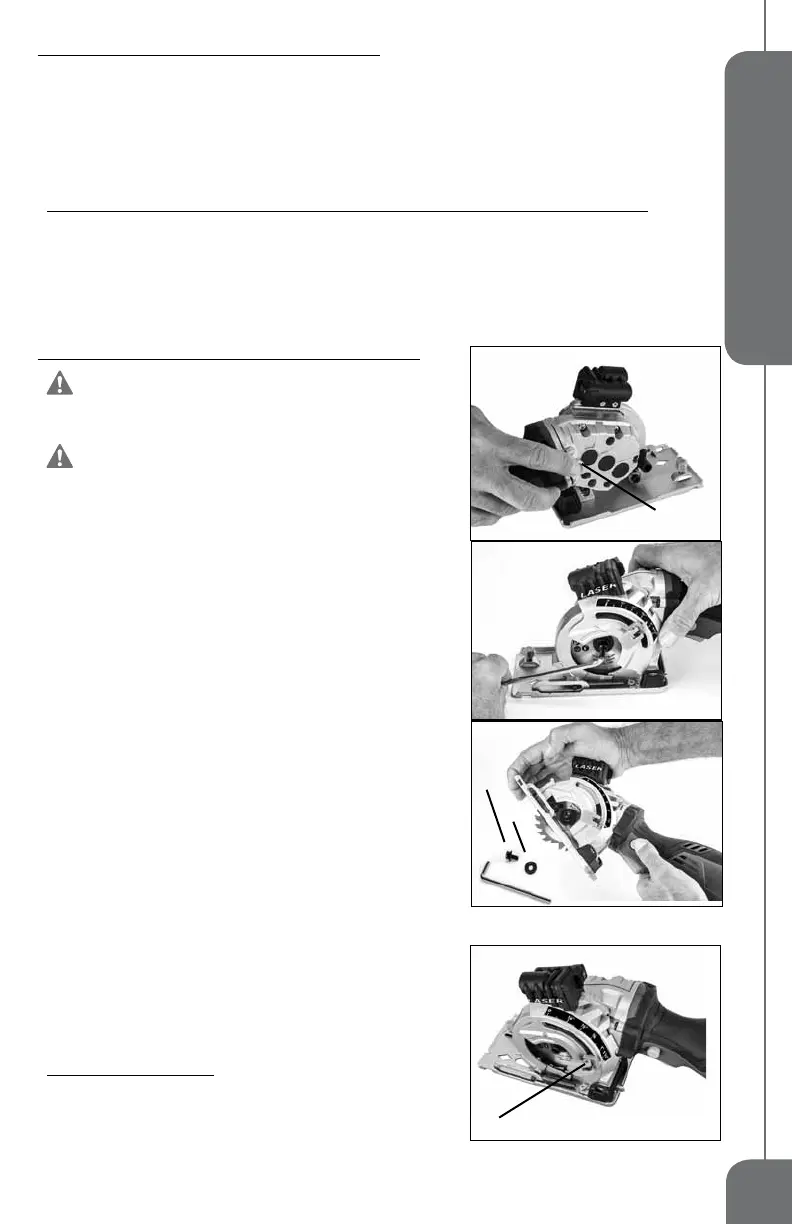

SETTING CUTTING DEPTH (FIG 5)

NOTE: Always maintain the correct blade depth setting. For all

cuts the blade depth should not exceed 1⁄4” below the material

being cut. Excessive blade depth increases the chance of saw

KICKBACK.

To Set the Cutting Depth

1. Release the cutting depth clamp (8).

2. Move indicator to the desired cutting depth.

3. Lock the cutting depth clamp to secure depth of cut.

FIG 3

FIG 2

14

FIG 5

8

FIG 4

12

31

FIG 3

Plunge circular saw 1

24T Carbide tipped blade 1

44T HSS blade 1

Diamond blade 1

Rip guide 1

Vacuum adaptor hose 1

Miter base assembly 1

Allen key 1

Storage bag 1

Operator’s manual 1

Loading...

Loading...