21

ENGLISH

ENGLISH

Fig. 30

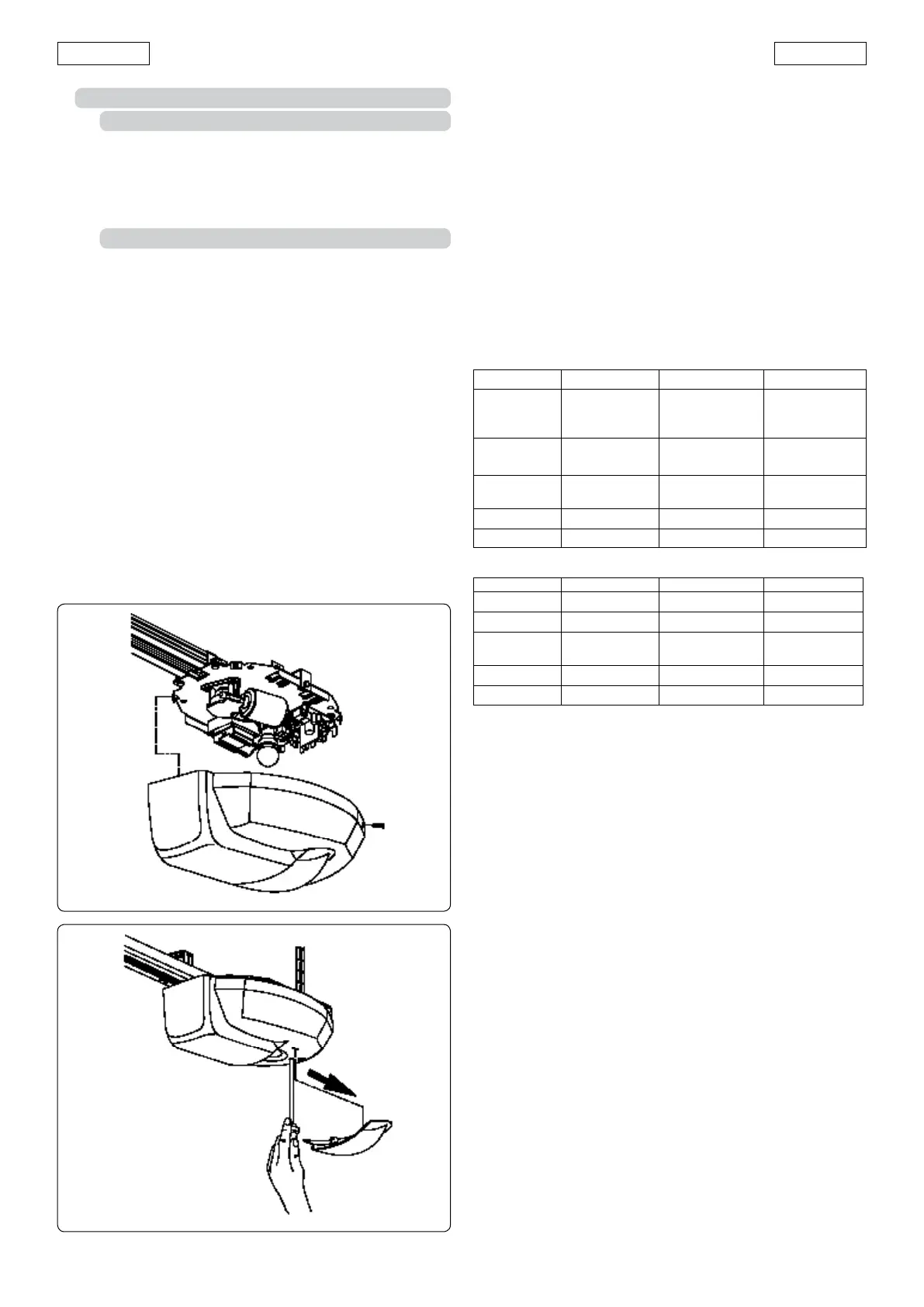

Fig. 29

DOOR STATUS OPEN STOP SAFETY DEVICES

CLOSED

Opens and

closes after the

pause time

No effect** No effect

OPEN FOR

PAUSE

Restarts pause

time count*

Stops *

Restarts pause

time count*

CLOSING

Reverses mo-

tion

Stops ** Reverses motion

OPENING No effect Stops ** No effect *

STOPPED Closes No effect** No effect *

DOOR STATUS OPEN STOP SAFETY DEVICES

CLOSED Open No effect** No effect

OPEN Closes No effect** No effect *

CLOSING

Reverses mo-

tion

Stops **

Reverses mo-

tion

OPENING Locks Stops ** No effect *

STOPPED Closes No effect** No effect *

8.5. PROGRAMMING

8.5.1. Card settings

Carry out the equipment settings by means of the Dip-Switch

DS1 to obtain the required operation. Max. thrust force can be

manually set on the operator G100 by turning the dip-switch

3 of DS1 to ON and adjusting the potentiometers TR1 (closing)

and TR2 (opening).

8.5.2. Learning

During the learning procedure, the obstacle detection device

is not operating. The STOP command and the closing safety

devices (FSW) are active; their intervention causes interruption

of the learning and anomaly signalling.

Refit the courtesy light.

The SET-UP cycle can be carried out even with the plastic

housing already fitted (fig. 29). To access the programming

button, remove the courtesy light ceiling fixture and insert a

screwdriver in the special passage (fig. 30). If, on pressing the

OPEN pushbutton during the learning phase, the operator does

not carry out any movement, check the correct positioning of

the housing.

If the SET-UP is carried out without the housing fitted, pay maxi-

mum attention not to touch live parts and the courtesy light.

The learning cycle defines:

- the necessary force for moving the door.

- deceleration points.

- door opening and closing stop points.

- pause time (in automatic logic).

Learning can be started with the operator blocked, regardless

of the door position.

The procedure also determines the operational logic.

The logic tables gives the behaviour of the automation in the

various conditions and following commands or safety device

intervention.

Learning can be carried out in automatic or manual mode; in

the latter case the deceleration points can be established in

opening and closing, whereas in automatic, the equipment

independently establishes the movement parameters.

If the procedure does not conclude correctly (e.g. due to

excessive friction during door movement), the equipment

signals the anomaly status (the courtesy light flashes slowly).

In this case, the procedure must be repeated after the cause

has been eliminated.

With the G100 operator it is possible to carry out a learning

procedure with thrust of 1000N instead of 600 or use the thrust

force manual adjustment.

AUTOMATIC Logic

SEMIAUTOMATIC Logic

* Prevents closing if pulse is maintained

** Prevents closing and/or opening if pulse is maintained

AUTOMATIC LEARNING WITH LOGIC “E” (SEMIAUTOMATIC)

Press the SET-UP pushbutton for 1 second. The courtesy light starts

to flash when the button is released.

1) After 8 seconds the operator automatically does a closing

operation until detecting the ground stop.

2) The operator starts the opening movement. Wait until it rea

-

ches the opening end travel or effect an OPEN command

in the position in which stopping of movement is required.

3) The operator closes the door.

4) Wait until the door reaches the ground stop and the operator

stops.

If the learning procedure was successful the courtesy light stops

flashing and stays on for 5 seconds.

During the 5 seconds, in order to reduce the load on the release

system, OPEN pulses can be sent within 2 seconds of each other

to reverse the carriage. One pulse equals 5 mm travel.

N.B.: Carriage reversing is only visible during normal operation

of the automatic system.

The electronic equipment establishes the deceleration points.

MANUAL LEARNING WITH LOGIC “E” (SEMIAUTOMATIC)

Press the SET-UP pushbutton for one second. The courtesy light

starts flashing when the button is released. Carry out the fol-

lowing procedure within 8 seconds (otherwise the operator will

carry out automatic learning).

1) Effect the 1st OPEN command: the operator carries out

a closing operation until detecting the ground stop and

stops.

2) Effect the 2nd OPEN command: the operator carries out an

opening movement.

Loading...

Loading...