21

GB

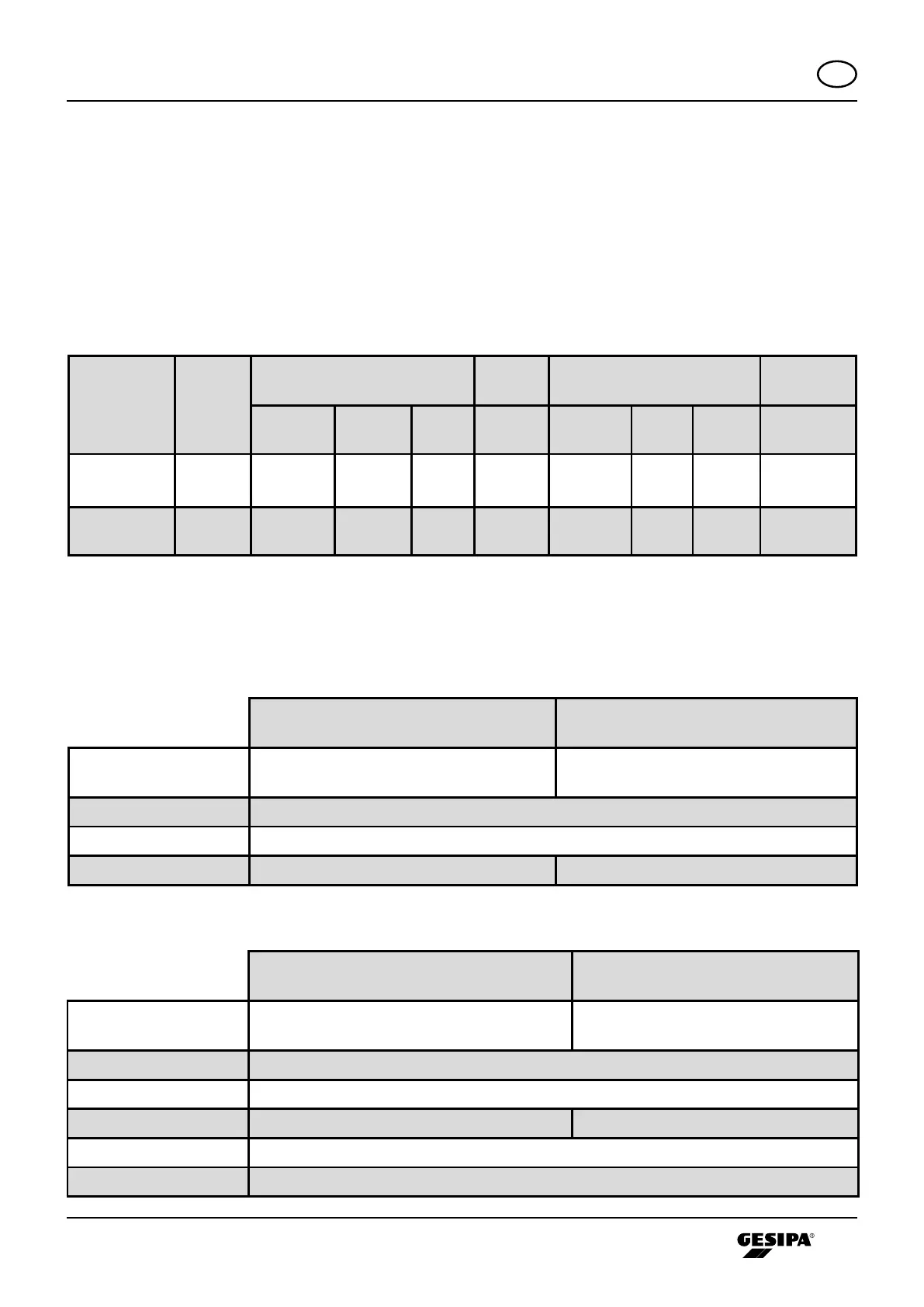

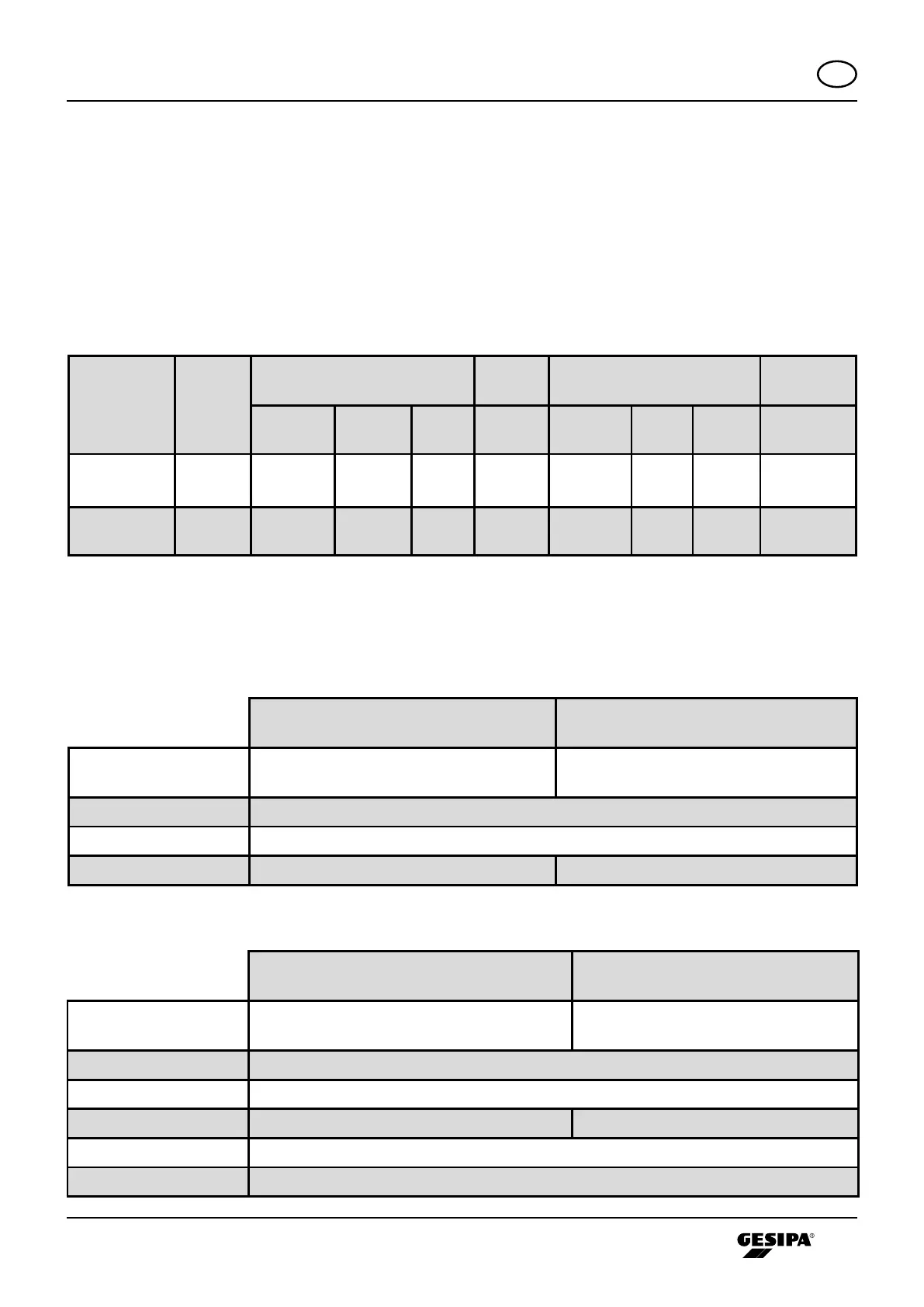

2.4 Equipment/accessories

2.5 Technical data

2.3 Working range

• Use only genuine spare parts for repairs.

• Repairs must be carried out only by skilled personnel. In case of doubt, always send in the

riveting tool to the manufacturer.

• 'RQRWXVHWRROZLWKRXWPDWHULDO7KHEOLQGULYHWFRXOGEHÀXQJIURPWKHULYHWLQJWRRO1HYHU

turn the riveting tool towards yourself or towards another person!

• The spent mandrel container (H) must remain mounted on the riveting tool during operation.

Tool type

Standard blind rivet G-Bulb BULB-TITE

®

MEGA

GRIP

®

All mate-

rials

Al

Steel

All ma-

terials

All ma-

terials

Al

Steel

All mate-

rials

AccuBird

®

Ø (mm) up to 5 up to 6 -

up to

4,8

-

up to

6,3

up to

6,3

-

PowerBird

®

Ø (mm) up to 6,4 up to 8 - up to 4

up to

7,7

- - up to 6,4

AccuBird

®

PowerBird

®

Nosepieces

17/32 in working position

17/27, 17/29 and 17/24 in magazine

17/45 in working position

17/36, 17/40 and 17/32 in magazine

Wrench WAF 12 (cover for nosepiece magazine)

Hanger Concealed in housing

Quick-change battery 1,3 Ah / 14,4 V 2,6 Ah / 14,4 V

AccuBird

®

PowerBird

®

Weight 2,0 kg (with battery) 2,2 (with battery)

Stroke 20 mm

Drive DC motor 14,4 V

Setting force 10.000 N 14.000 N

Noise emission Measurement uncertainty K = 3 dB

Vibration Measurement uncertainty K = 1.5 m/s²

To avoid blockages, it is recommended that the corresponding jaw pusher, according to table

2.6, is used!

Loading...

Loading...