Clean all removed parts and the body.

Inspect all parts to ensure they are in perfect

condition.

Replace damaged parts.

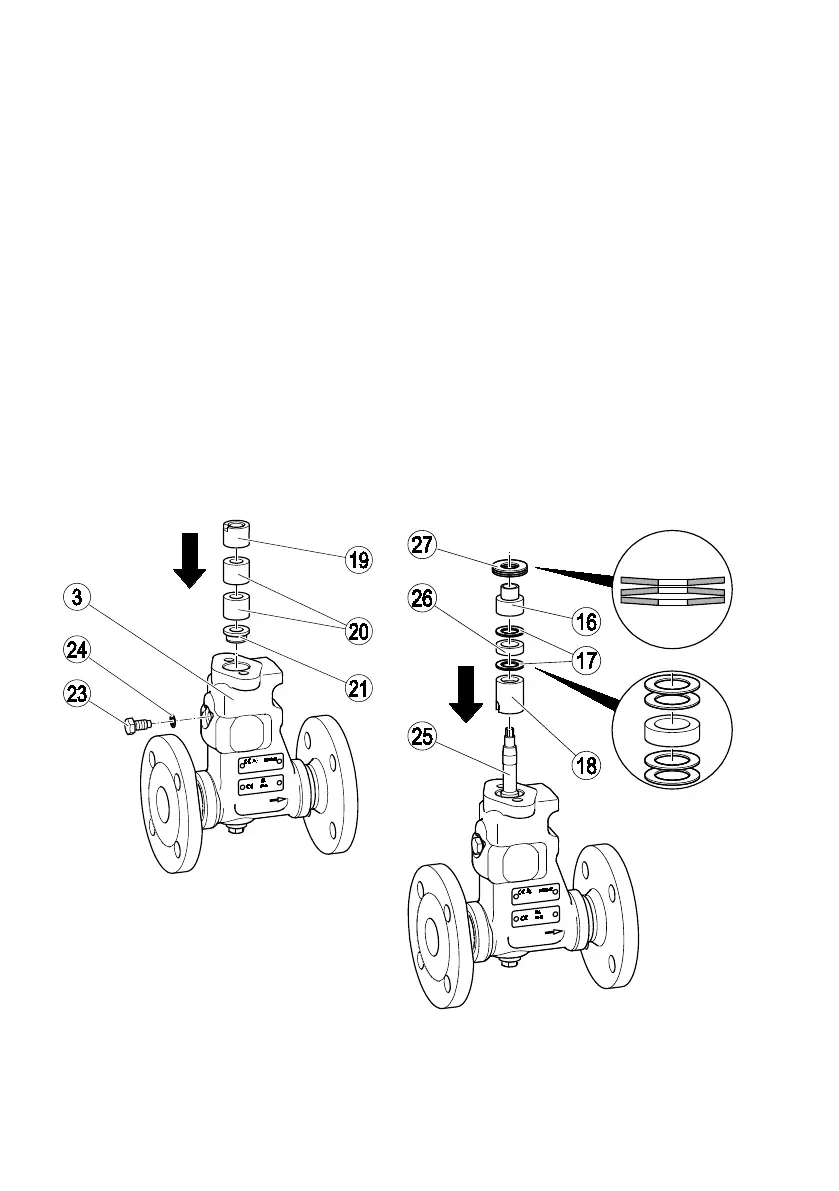

Insert the seat bushing (21) in the body (3) using

adhesive.

The adhesive must have the same properties as

Loctite

®

620.

Insert the two stepped bushings (20) in the

body.

Insert the anti-wear bushing (19) in the body.

Position the anti-wear bushing so that the

retaining groove points towards the hole for the

locking screw.

Insert the sealing ring (24).

Hand-tighten the locking screw (23).

The torque for the locking screw varies depending

on the equipment:

For models with DN 15 to DN 32, the required

torque is 5 Nm.

For models with DN 40 and DN 50, the required

torque is 11 Nm.

Tighten the locking screw to the specified

torque.

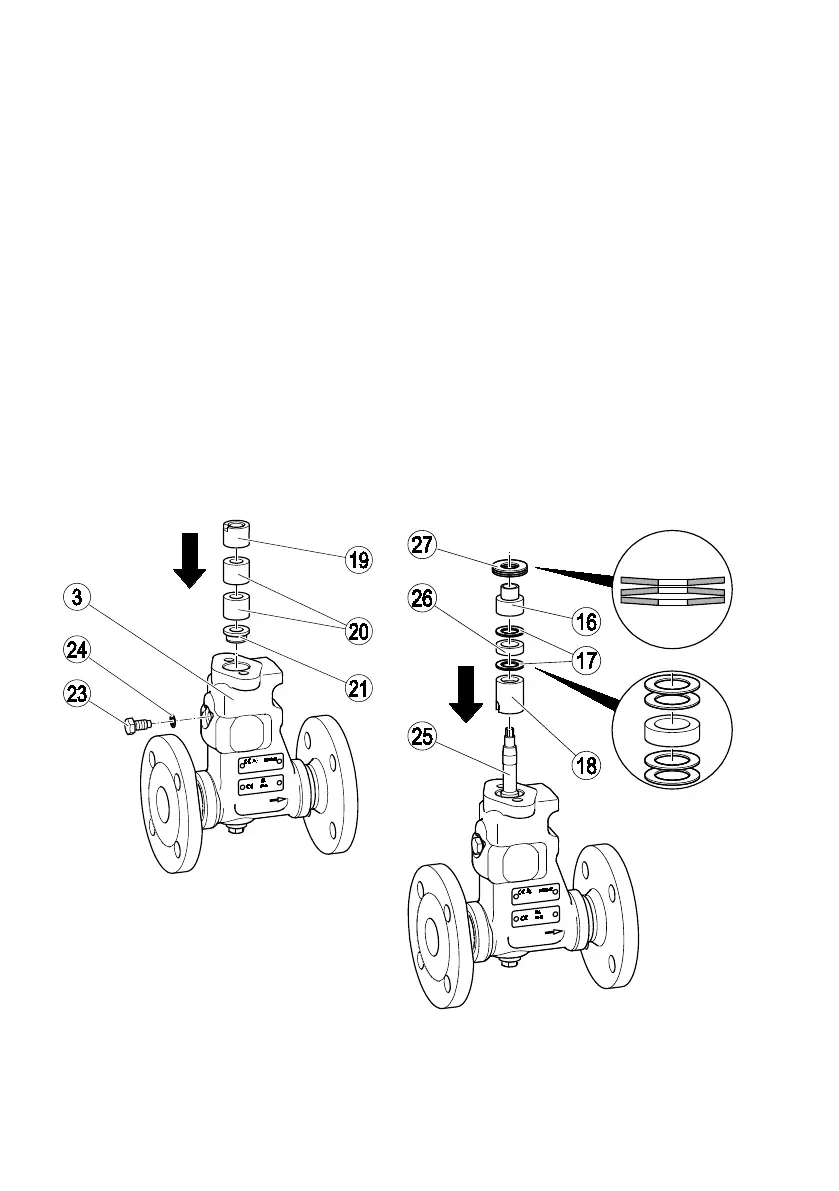

Position the guide bushing (18) so that the

retaining groove points towards the locking

screw.

Insert the guide bushing (18).

Insert the new stuffing box comprising the

packing ring (26) and four wipers (17) as

shown.

Coat the thread and sealing surface of the

nozzle needle (25) with lubricant.

The lubricant must have the same properties as

WINIX

®

2010.

Insert the nozzle needle in the body.

Screw the nozzle needle into the guide bushing

by two full turns.

Position the spring bushing (16) on the nozzle

needle.

Position the disc springs (27) on the spring

bushing in the position shown.

Loading...

Loading...