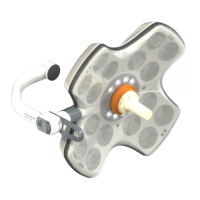

Atrium OCEAN

Water Seal Chest Drain

• Set up

Step 1. Fill water seal to 2 cm line

Hold funnel down and fill to the top. Raise funnel to

empty water into water seal to 2 cm line.

Step 2. Fill suction control to desired pressure level(A)

Remove the tethered vent plug, pour water, and

replace vent plug.

Step 3. Connect chest drain to patient

Connect chest drain to patient prior to initiating suction.

Step 4. Connect chest drain to suction

To apply suction, connect suction source line directly

to the suction control stopcock or suction connector

provided. Adjust the suction control stopcock or

suction control source as needed to increase or

decrease suction control bubbling.

Have a question or need help in a hurry?

Call Maquet toll free at 1-800-528-7486.

What to check during system operation

• Suction control stopcock

The suction control stopcock regulates vacuum to the

chest drain. It provides effective control of suction control

bubbling and allows efficient use with any unregulated

suction source. The stopcock must be ON for initial system

set up and should not be turned OFF during patient use.

During patient transport or when suction is not

operating, it is not recommended to turn the stopcock

off or to clamp off suction tube.

• Verifying system operation

Water seal and suction control chambers must be filled

and maintained to prescribed levels to ensure proper

operation and should be checked regularly when used for

extended periods. Water seal should be maintained at 2

cm line and suction control chamber should bubble gently

when connected to suction. Adjust stopcock or suction

source as needed to increase or decrease suction control

bubbling. As required, additional water may be added by

a 19 gauge or smaller needle and syringe via the grommet

located on the back.

• Placement of unit

Always place chest drain below the patient’s chest in an

upright position. To avoid accidental knock-over, open

the floor stand for secure placement on floor or hang the

system bedside with the hangers provided.

• Recording drainage volume

The collection chamber incorporates a writing surface with

easy-to-read fluid level graduations. Please refer to indivi-

dual product inserts for specific model graduations.

• Observing water seal for patient air leaks

When air bubbles are observed going from right to left in

the air leak monitor, this will confirm a patient air leak.

Continuous

bubbling in the

water seal air leak

monitor will confirm a

persistent air leak.

Intermittent

bubbling with float

ball oscillation will

confirm the presence of an intermittent air leak.

No bubbling with minimal float ball oscillation at bottom of

water seal will indicate no air leak is present.

• Graduated air leak monitor

For those models with a graduated air leak monitor, air leak

bubbling can range from 1 (low) to 5 (high). Air bubbles

create an easy to follow air leak pattern for monitoring

patient air leak trends.

• Observing graduated water seal column for changes

in patient pressure

Patient pressure can be determined by observing the

level of the blue water

and small float ball in the

graduated water seal

column. With suction

operating, patient

pressure will equal the

suction control setting

plus the graduated water

seal column level only.

For gravity drainage (no

suction) patient pressure will equal the graduated water seal

column level only.

• High negativity float valve

The high negativity float valve,

with its controlled release action,

enables the thoracic patient to draw

as much intrathoracic pressure as

is required during each respiratory

cycle. During prolonged episodes

of extreme negative pressure, the

controlled release system will auto-

matically relieve excess vacuum to

a lower pressure level.

• Manual high negativity vent

To lower the height of the water seal column or to lower

patient pressure when connected to suction, depress the

manual vent located on top of the drain until the float valve

releases and the water column returns to the desired level.

Do not use manual

vent to lower water

seal column when suc-

tion is not operating or

when the patient is on

gravity drainage.

• To prescribe suction pressure greater than -20 cmH

2

0

Suction pressure greater than -20 cmH

2

O can be imposed

directly by a graduated wall regulator or portable pump

by taping over the vent-plug with non-porous tape and

reading vacuum pressure directly from regulator or pump.

Vacuum pressures greater than -40 mmHg are not

recommended.

• Sampling patient drainage

Sampling of patient drainage must be in accordance with

approved hospital infection control standards. Selected

models include a needleless Luer port on the patient tube

connector for sampling patient drainage. Alcohol swab the

Luer port prior to syringe attachment (no needle). Fluid

samples can also be taken directly from the patient tube

by forming a temporary dependent loop and inserting a

19 gauge needle at an oblique angle. Alcohol swab the

patient tube prior to inserting syringe at a shallow angle.

Do not puncture patient tube with an 18 gauge or larger

needle.

• Positive pressure protection

The positive pressure release valve, located on top of

drain, opens to release accumulated positive pressure. Do

not obstruct the positive pressure release valve.

• System disconnection

For models equipped with an in-line connector, close

patient tube clamp prior to dis connecting chest drain

patient tube from patient. Clamp off all indwelling thoracic

catheters prior to disconnecting chest drain from patient.

• System disposal

Disposal of chest drain and its contents should be in

accordance with all applicable regulations.

OFF

ON

Do not vent when suction Is not operating

A Suction Control Chamber

B Water Seal Chamber

C Air Leak Monitor

D Collection Chamber

E Easy-to-Grip Handle

F Positive Pressure Release Valve

G Manual High Negativity Vent

H Multi-position Hangers

I In-line Connector

J Needleless Access Port

K Patient Pressure Float Ball

L Swing Out Floor Stand

M Patient Tube Clamp

N Patient Connector

F

G

E

I

J

H

A

B

D

C

N

M

L

K

Loading...

Loading...