© Dimplex Boilers 2008

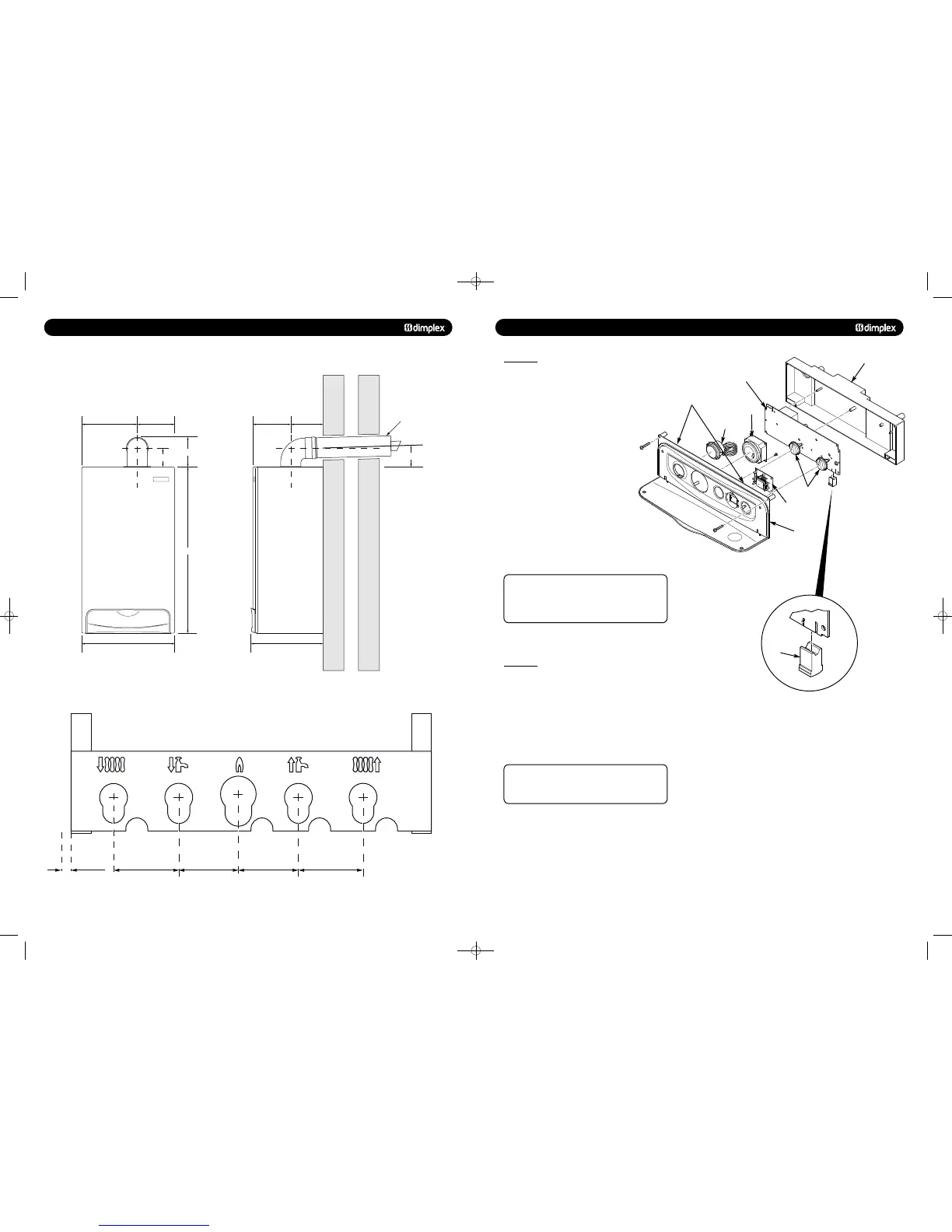

65mm 60mm 60mm 65mm

10mm

Condensate

Drain

CH Flow

(22mm)

Domestic Hot

Water Outlet

(15mm)

Gas Inlet

(22mm)

Mains Cold

Water Inlet

(15mm)

CH Return

(22mm)

Tap Rail

446mm

264mm 182mm

796mm

150mm

94mm

333mm

148mm185mm

1.5° - 3.0°

Tube Ø 100mm

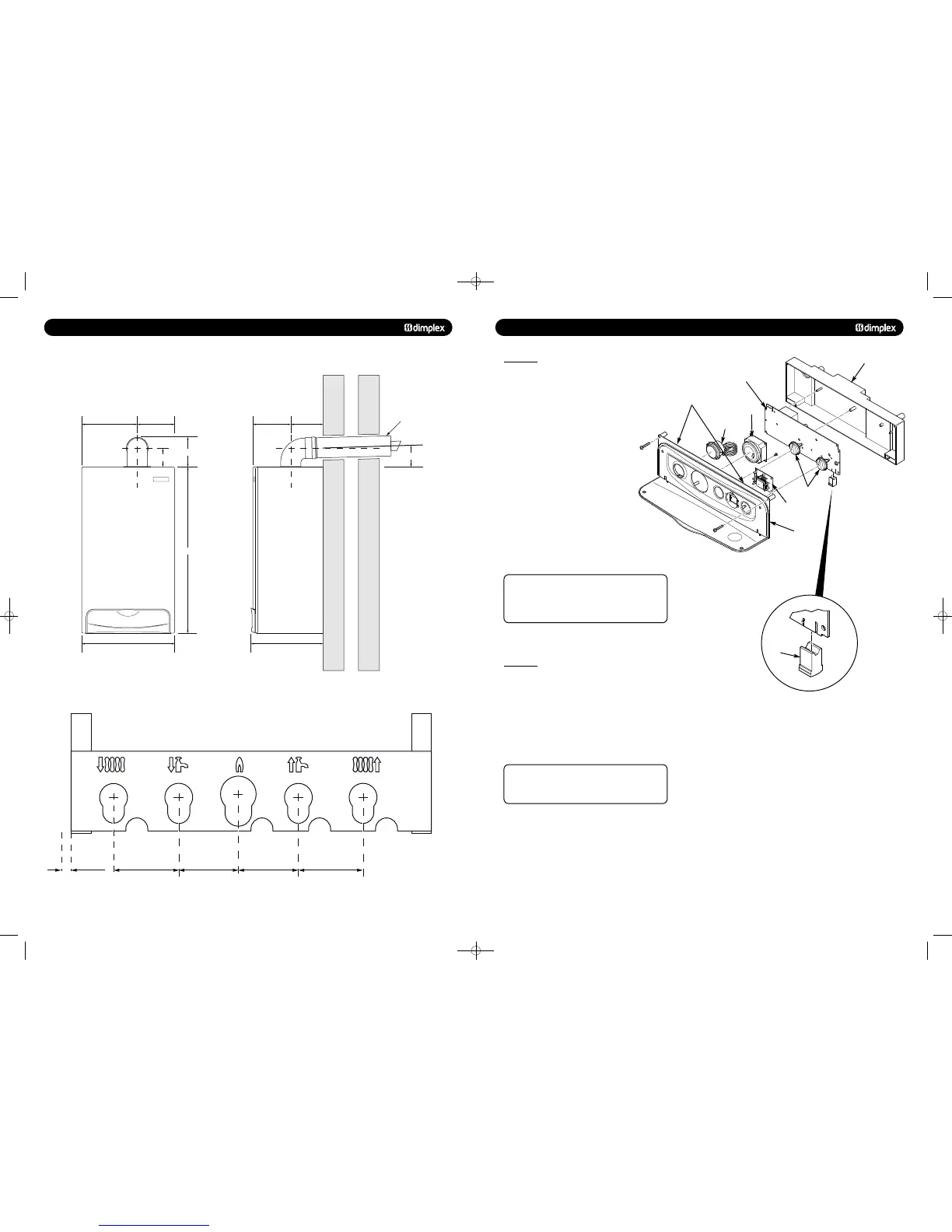

13.0 CHANGING COMPONENTS

13.18 PCB

1. Ensure supply voltage is fully isolated.

2. Undo the screws holding the control box and gently ease

the box forward (Fig. 69).

3. Locate the retaining barbs on the top of the fascia and

unclip them from the control box.

4. Unclip the PCB from the plastic control box.

5. Note the positions of all the connections on the PCB

and disconnect them.

(DO NOT REMOVE THE YELLOW BCC (Fig. 69))

6. Carefully unclip and remove the ribbon cable

from the PCB and withdraw.

7. Fit all the connection plugs to the new PCB

including the ribbon cable, take care not to damage

the PCB.

8. Unless specifically instructed N

to do so by the Dimplex

Service Department, always fit the new BCC if supplied with

the replacement PCB.

Always double check the label on the BCC card to

ensure it is the correct BCC for the boiler model to which it

is being fitted. Never fit an incorrect BCC, as this is

extremely dangerous and could result in serious injury or

death.

9. Reassemble in reverse order, ensuring that the control knob

are reset to their previous positions

© Dimplex Boilers 2008

1. Ensure supply voltage is fully isolated.

2. Dismantle the control box as described above to gain access

to the PCB (Fig. 69).

3. Note the orientation of the existing BCC (if fitted) and

carefully remove by sliding it off the edge of the PCB.

4. Re-fit the new BCC by sliding it onto the edge of the PCB,

ensuring the orientation is correct.

Always double check the label on the BCC card to

ensure it is the correct BCC for the boiler model to which it

is being fitted.

NEVER FIT AN INCORRECT BCC.

5. Reassemble as above.

6. Power up boiler, and briefly press the reset button, wait for

at least 5 seconds and then briefly press the reset button

again.

7. The boiler should now be checked for operation in DHW and

CH modes.

PCB

Facia

Control Box

Retaining Barbs

Pressure

Gauge

Timer

User Interface

Control Knobs

BCC

48pp MANUAL SPREADS 19/10/10 08:36 Page 10

Loading...

Loading...