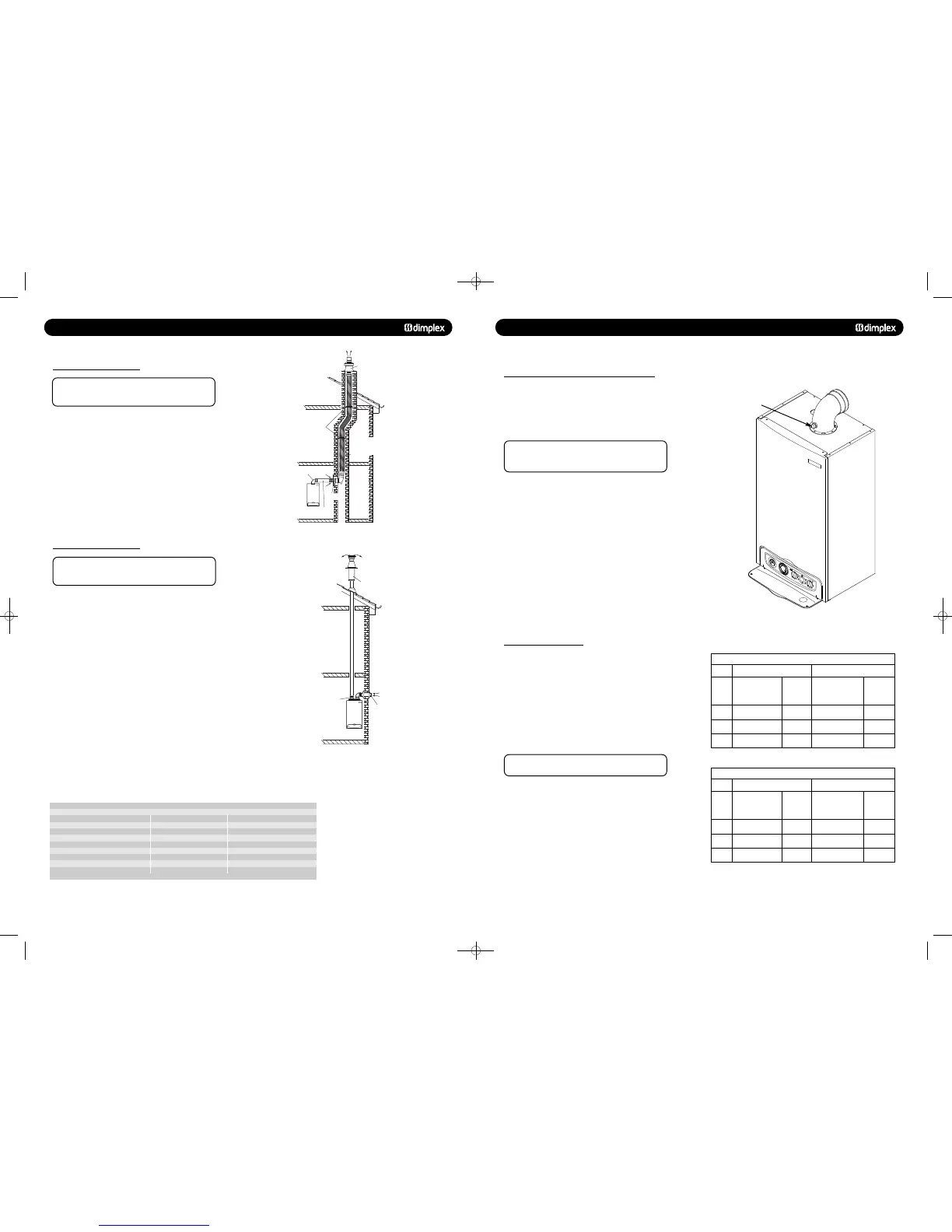

8.0 FLUE OPTIONS

8.8 Kit E Chimney Flue Liner Kit

(B23) - Part no. 956082

Note:

Dimplex Combi 38 - Maximum flue length 21m, and 30m

for all other appliances.

This kit is suitable for open flue application in accordance with

BS5440 where a room sealed flue installation is impractical.

The kit comprises of a flue adaptor from the appliance to the

chimney, a flexible plastic flue liner with connection parts and

chimney terminal (see Fig. 27). Where an open flue system is

used, then an air vent must be provided in the same room or

internal space as the flue duct air inlet, see section 7.3.

For installation details refer to the flue kit instructions.

Maximum flue resistive length = 30m.

A flue system can be built up from the components detailed in

table 8.10, but the total flue resistance must not exceed the

maximum stated.

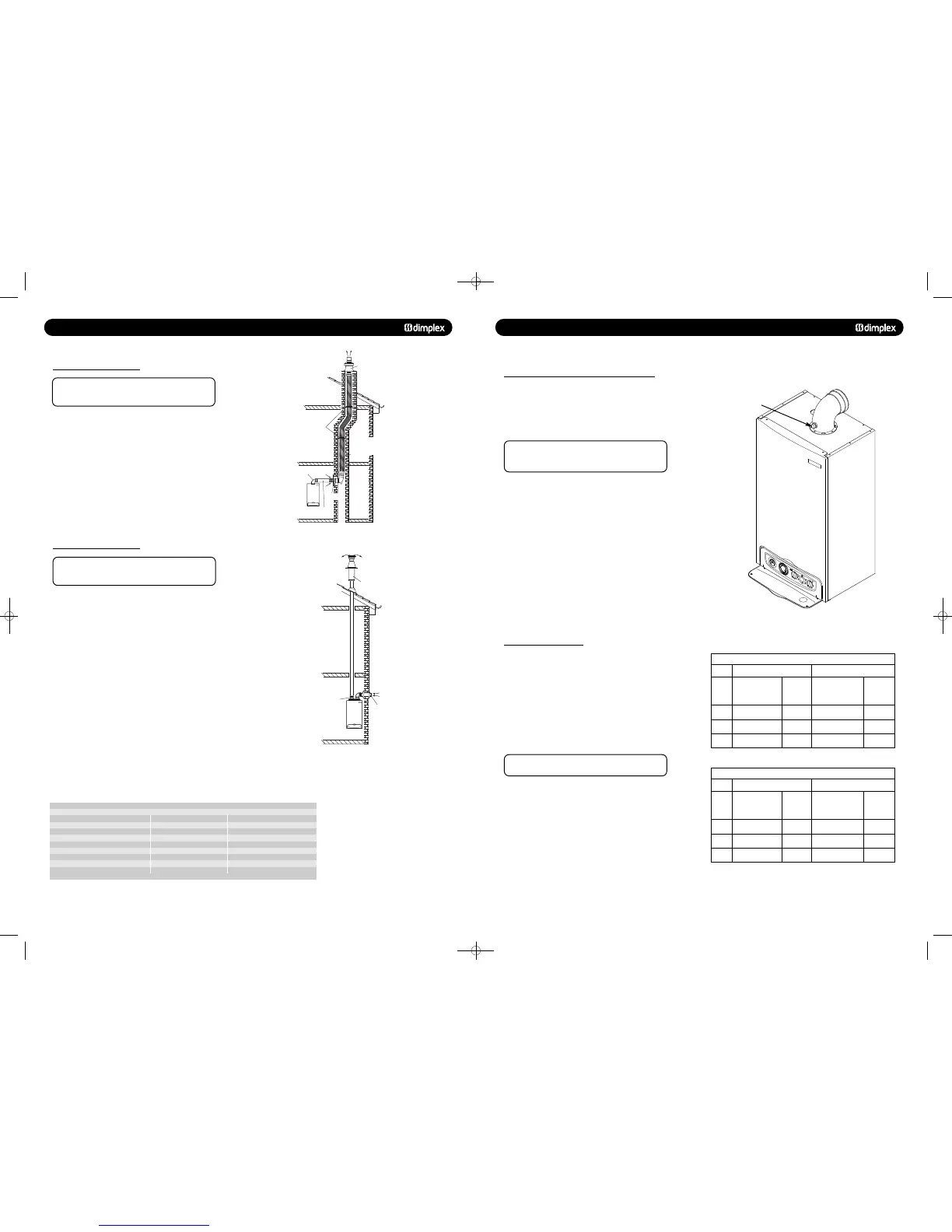

8.9 Kit F: Twin Flue System

(C53) - Part no. 956080

Note:

Dimplex Combi 38 - Maximum flue length 21m, and 30m

for all other appliances.

This flue system kit is designed for installations where the air

intake position is different than the flue duct exit point. The kit

comprises of a twin adaptor from which the air intake is taken

from the adjacent outside wall (see Fig. 28) and the flue duct

is routed vertically through the roof.

It has to be noted that the flue duct is under pressure when

the appliance is in operation and the duct can leak poisonous

carbon monoxide if the duct components are not correctly

assembled. It is n

recommended to route the flue duct

through living space areas, i.e. bedrooms, living rooms etc.

For installation details refer to the instructions provided with

the twin flued kit.

For C53 flue systems the terminal for the supply of

combustion air and for the evacuation of combustion products

shall not be installed on opposite walls of the building.

Maximum flue resistance permitted for a twin flued system

= 52 Pa

Minimum flue resistance permitted for a twin flued system

= 23.5 Pa

Centralising brackets

Chimney terminal

93 flanged elbow (concentric)

with sampling point

Ø60/100mm concentric

chimney adaptor pipe.

In replacement installations,

the chimney has to be

cleared of debris and

all flue parts.

Chimney

plate

Flexible corrugated plastic flue liner

Ø80mm according to EN 14471

Max. length 30m.

Min. length 5m.

KIT E

Chimney flue liner kit - Part no. 956082

Flue Component Flue Resistance (Pa) Part Number

Twin Flue Adaptor (required) 9.5 -

Air Inlet Terminal (required) 3 -

Chimney Terminal (required) 0.5 -

80 mm dia straight duct 1 metre 1 956101

80 mm dia straight duct 2 metre 2 956102

90° Elbow (80/80) 8 956100

45° Elbow (80/80) 4 956099

A flue system can be built up from the components detailed in the table, but the total flue

resistance must not exceed the maximum stated.

Ø80mm air intake

Split flue system

Roof terminal with pitched

roof flashing kit.

If the flue pipe passes

through compartment

from wall/floors, the

requirements set out

in Building Regulations

Part B must be followe

d.

Ø80mm twin adaptor

with sampling point.

If the flue pipe passes

through habitable rooms

within the same dwelling,

the flue pipe must be

routed through vented

ducts.

The flue resistance for the

following accessories has

to be considered.

Ø80mm flue extension

90 elbow

45 elbow

Split pipe vertical

flue outlet kit -

Part no. 956080

Kit F

!

12.0 SERVICING AND MAINTENANCE

12.1 ROUTINE SERVICING AND ALL MAINTENANCE THAT

INVOLVES THE EXCHANGE OF PART OF THE

COMBUSTION CIRCUIT

1. During routine servicing, e.g. an annual service check, and

after all maintenance that involves the exchange of parts of

the combustion circuit, we recommend that (in this order) the

integrity of the full flue system and combustion circuit seals,

the inlet gas pressure, gas rate and combustion performance is

verified.

The combustion circuit on this appliance comprises

of the PCB, fan, air/gas ratio valve, burner, burner door,

combustion box door, injector and flue system.

2. To ensure continued safe and efficient operation of the

appliance it is recommended that the boiler is serviced at least

annually. Servicing must be performed by a competent person.

BS 7967-1 gives guidance on identifying and managing

sources of fumes, smells, spillage/leakage of combustion

products and carbon monoxide detector activation.

On any service visit always check;

a. Condition of flue system, both air and combustion products

ducts.

b. Condition of seals and joints.

c. For evidence of leakage of combustion products.

d. For evidence of heat staining.

e. For operation at maximum heat input.

f. The general condition of the boiler and its components.

1. Combustion checks must be carried out with the outercase

fitted.

2. Remove the sampling cap from the boiler flue elbow or

boiler vertical flue adaptor.

3. Insert the probe from the portable electronic combustion

analyser into the sampling point.

4. With the appliance operational, connect the flue gas

analyser to the flue sampling point as shown in Fig. 47.

The outercase must be fitted for all combustion

checks.

5. With the boiler at minimum rate and then at maximum rate

(allowing the combustion to stabilise at each rate before taking

a reading) carry out the combustion checks as follows:

COMBUSTION CHECKS AT MINIMUM RATE

6. The combustion values at minimum gas rate and maximum

gas rate must be checked using a suitable calibrated flue gas

analyser. Further guidance is detailed in BS7967 parts 1 to 4.

7. Set the boiler into Service Mode at Min Rate

(see section 11.1).

8. Check the Carbon Monoxide (CO) and Carbon Dioxide (CO

2

)

readings are within the range quoted in the tables opposite

(Table 1).

© Dimplex Boilers 2008

C

o

m

f

or

t

+

1

13

2

1

4

3

1

5

4

1

6

5

1

7

6

1

8

7

1

9

8

2

0

9

2

1

1

0

2

2

1

1

2

3

1

2

2

4

0

1

0

1

2

b

a

r

3

4

Carbon

Monoxide

CO

p.p.m

0 - 40

0 - 40

0 - 30

Carbon

Dioxide

CO

2

%

8.2 - 8.6

8.7 - 9.1

8.3 - 8.7

Carbon

Monoxide

CO

p.p.m

0 - 40

0 - 40

0 - 40

Carbon

Dioxide

CO

2

%

10.2 - 10.6

10.2 - 10.6

10.4 - 10.8

Carbon

Monoxide

CO

p.p.m

40 - 120

40 - 120

40 - 120

Carbon

Dioxide

CO

2

%

8.8 - 9.2

9.1 - 9.5

8.9 - 9.3

Carbon

Monoxide

CO

p.p.m

80 - 160

100 - 180

70 - 150

Carbon

Dioxide

CO

2

%

10.5 - 10.9

10.7 - 11.1

10.5 - 10.9

48pp MANUAL SPREADS 19/10/10 08:36 Page 20

Loading...

Loading...