0020117819_01 - 05/11 - Glow-worm

- 23 -

- weather resistant.

- equipped with wires adapted to appliance’s power rating.

• Connect the heat pump to an electrical panel via an

independent protection system (diff erential breaker with at

least 3 mm between each contact). See the table below.

Additional protection may be required during installation to

ensure buff er category II.

The power supply cut-off devices must allow complete

disconnection of the power under the conditions required for

over-voltage category III.

Description Unit 7 12 14

Electricity supply

V-ph-

Hz

230 - 1 - 50

Acceptable voltage range V 207/254

Maximum power absorbed kW 2.7 5.1 5.1

Maximum current A 14 23 20

Power fuse (gL) A 15 Type B 25 Type D 25 Type D

Maximum current in glycol

pump

A2

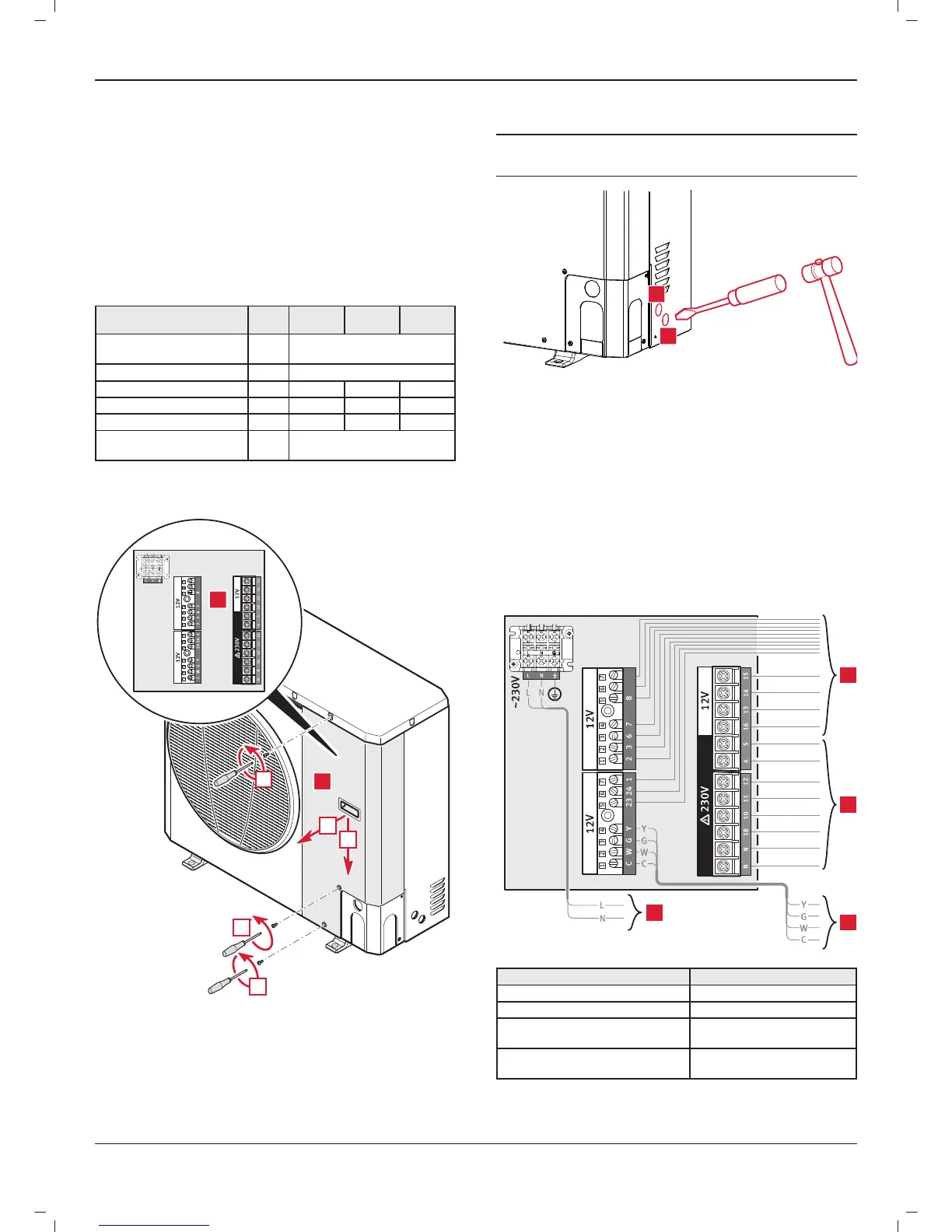

13.1 Access to main board

B

A

A

A

C

2

1

Key

1 Terminal blocks for 230 V and 12 V connection

2 Front panel

• Remove the fastening screws (A).

• Slide the front panel (2) downwards (B) and pull it towards

yourself (B) using the handle.

• To close the appliance, carry out the operations in reverse order.

13.2 Cable passage

e

The low and mains voltage cables must be inserted in

diff erent sleeves.

2

1

Key

1 Mains-voltage cable passage

2 Low-voltage cable passage

• Insert the electrical power cables in passages (1) and (2)

provided for this purpose.

• Make sure that the electrical cables are not in contact with the

compressor and the hot pipes.

• Fix the electrical cables with the clamps installed inside the

heat pump.

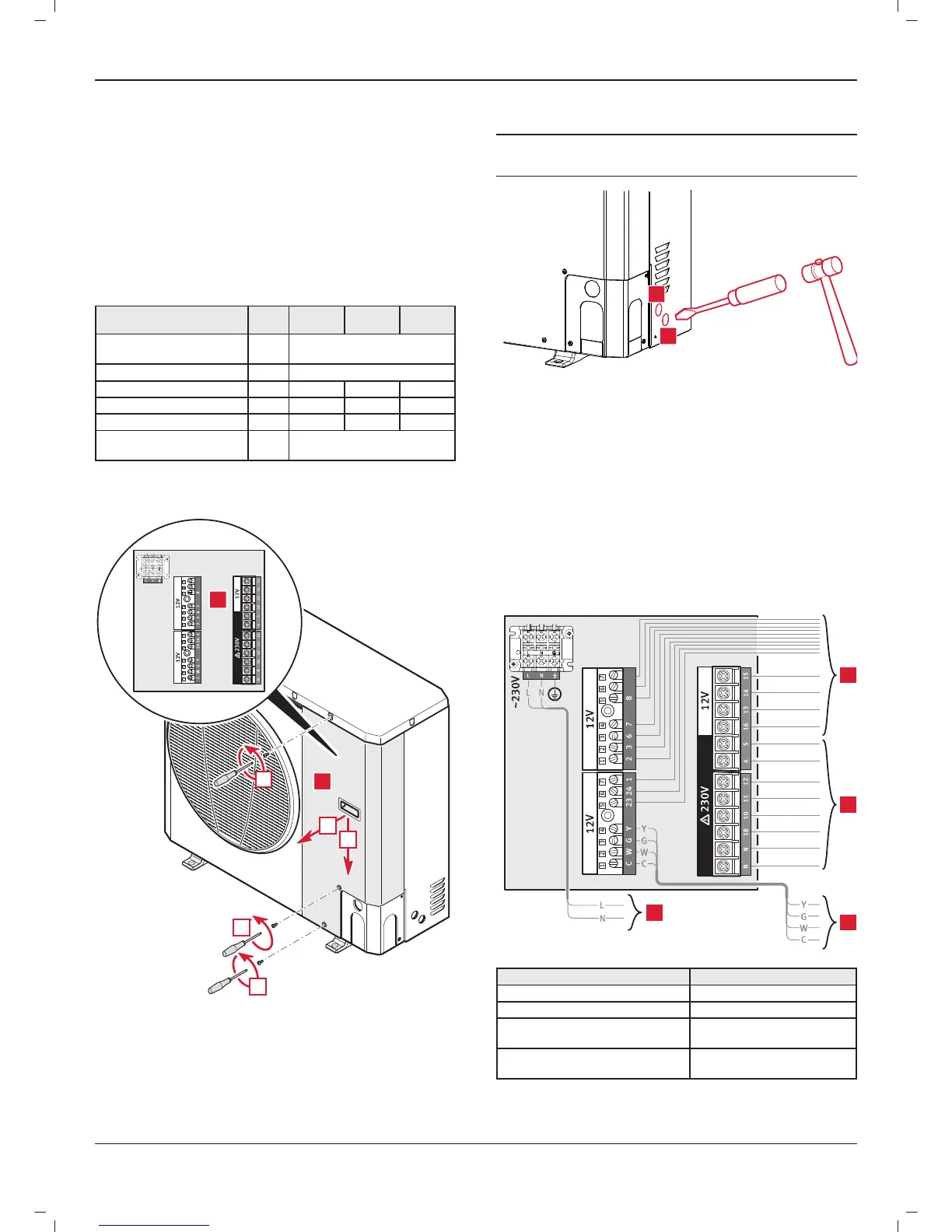

13.4 Electrical wiring

3

2

4

1

Key Recommended cable section

1 230 V power cable H07RN-F 3 x 2.5 mm²

2 12 V cable 0.75 mm²

3

230 V cable (outputs 2A

maximum)

0.75 mm²

4

Connection cable for the

command unit

4 x 0.75 mm²

INSTALLATION

Loading...

Loading...