36

221469B

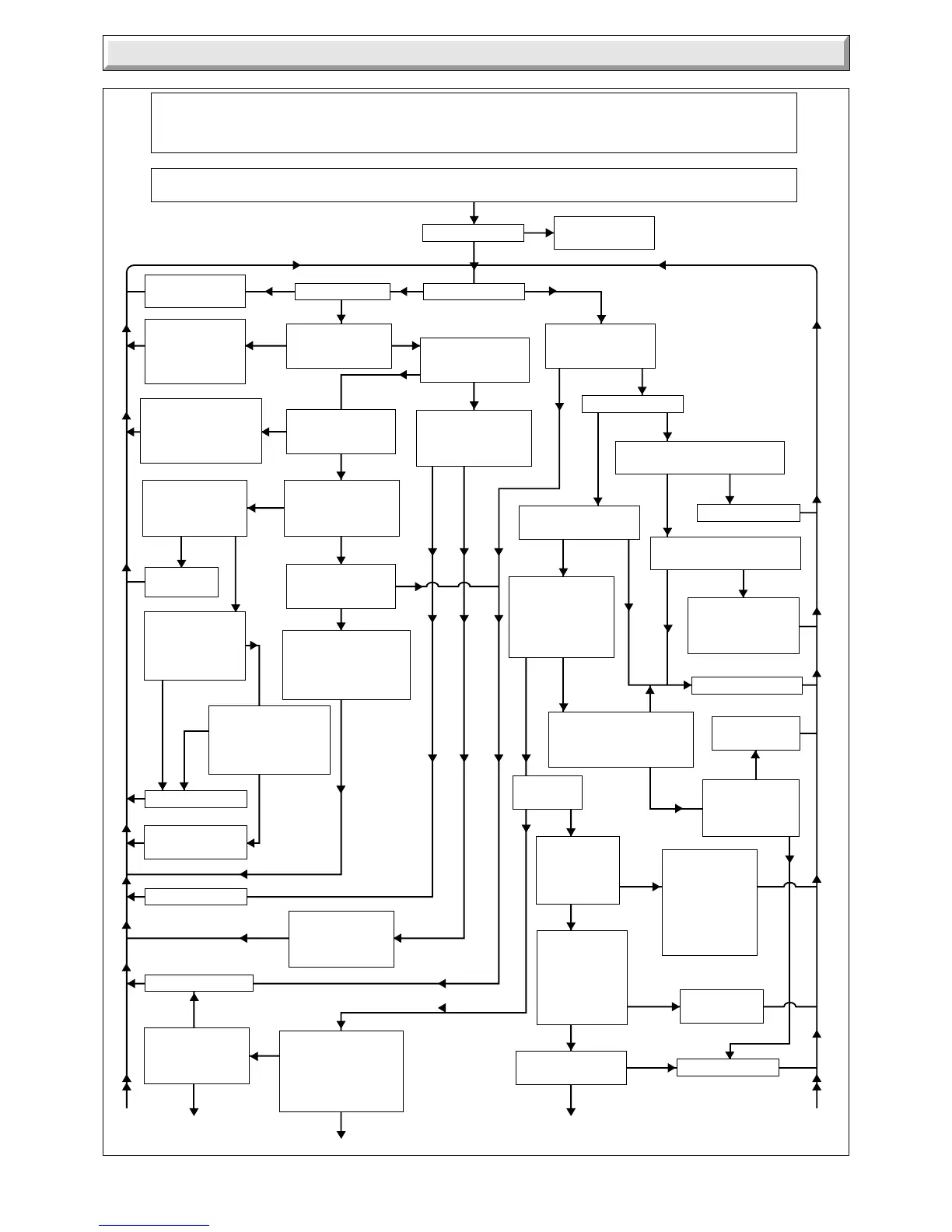

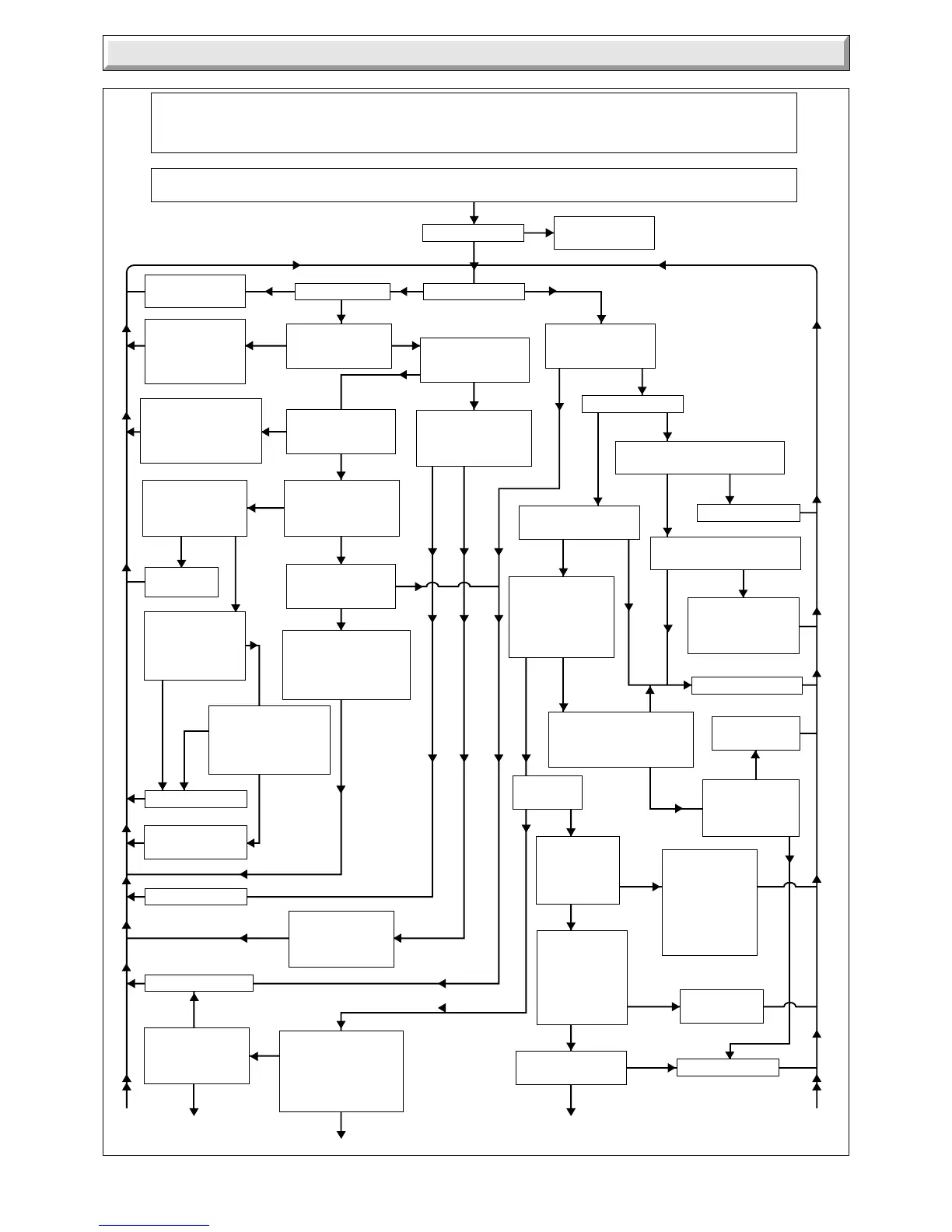

START

Carry out the initial fault finding checks described in section 3.1 and 3.4. Check that gas, water and electricity are available at the boiler.

There must be no external voltage applied to the control board via the central heating controls to the P.C.B. Before commencement of test,

isolate the boiler from the electricity supply, ensure that the remote controls are not calling for duty (no red link in plug and socket).

Refer to the functional flow diagrams in conjunction with the following fault finding.

Remove the outer case, control housing and its cover. Check all connections on the control board and the boiler components, rectify or

renew as necessary. A dummy two-way connector is provided for ease of testing continuity, a spare fuse is also provided.

Can pilot be lit

Does pump run?Does boiler light?

Faulty flowswitch,

replace.

Refer to pilot fault

finding

Is there 240V AC

across 'pump' pins

on block 2 on P.C.B?

Is there 240V AC

across L & N pins on

block 3 on P.C.B.?

After approx 30

seconds. Does pump

stop?

Isolate supply. Is

there continuity across

fuse FSI on P.C.B.?

Isolate supply. Is

there continuity across

fuse FS 2 on P.C.B.?

Restore supply. Is there

24V AC across 'TXR'

24V AC pins on block

1 on P.C.B.?

Increase D.H.W. flow to

11.4 litres/minute. Is

burner pressure constant

at approx :

S.I.T. 15.7mbar?

Honeywell 16.1mbar?

Isolate supply, check

continuity between

supply and P.C.B.

via plug and socket.

Rectify if necessary.

Check P.C.B.connections

and external wiring for

shorting to E or N

rectify if necessary,

replace fuse.

Remove terminal cover

from pump. Is there

240V AC across L and

N terminals on pump?

Is there between 15

and 30 V DC across

'modulator' pins on

block 1 on P.C.B.?

Isolate supply. Is

there continuity

between P.C.B. and

transformer primary

winding?

Is there 240V AC

across TXR 240V AC

pins on block 2 on

P.C.B.?

Faulty P.C.B., replace.

Faulty pump, replace.

Rectify as necessary.

Faulty P.C.B.

replace.

Faulty transformer,

replace.

Isolate supply. Check

continuity between

P.C.B. and pump.

Rectify if necessary.

Disconnect block 1 from

P.C.B. Is there continuity

between TXR 24V pins

on block 1 secondary

pins 6&7 on transformer?

Check P.C.B. connections

and wiring external to

control box for shorting to

E and N. Rectify if

necessary replace fuse.

Does Fan run?

Is there 240V AC across L and N

terminals of fan?

Faulty fan, replace.

Rectify as necessary.

Are D.H.W. thermistor

connections sound?

Isolate supply.

Remove electrical

connectors from

pressure switch.

Is there continuity

across switch

terminals?

Faulty pressure

switch. Replace.

Isolate supply.

Check heating

system for leaks.

Rectify if

necessary. Refill

& vent ensuring

automatic air vent

cap is open.

Check system

pressure. Is

there a minimum

pressure of

0.6 bar?

Does main

burner light?

Is there continuity

between P.C.B.

and flowswitch in

line connectors?

Isolate supply. Disconnect

block 4 from P.C.B. Is there

continuity across flowswitch

pins on block 4?

After approx 30 seconds

does fan speed reduce?

Is there 240V AC across 'fan'

pins on block 2 on P.C.B.?

Faulty flowswitch

replace.

Faulty P.C.B., replace.

Isolate supply. Check

continuity between

fan and P.C.B. Rectify

if necessary.

Set selector switch

to "on". With D.H.W.

flow rate of at least

4 litres/minute. Does

fan speed increase

to maximum?

NO

NO

YES

NO

NO

NO

YES

YES

YES

NO

NO

NO

NO

YES

NO

YES

NO

YES

NO

YES

YES

NO

YES

NO

YES

YES

NO

YES

NO

YES

NO

YES

NOYES

YES

NO

YES

NO

NO

NOYES

YES

NO

YES

NO YES

Continued

Continued

Continued

YES

YES NO

YES

NO

3 Fault Finding

Diagram 3.7

4490

Loading...

Loading...