37

221469B

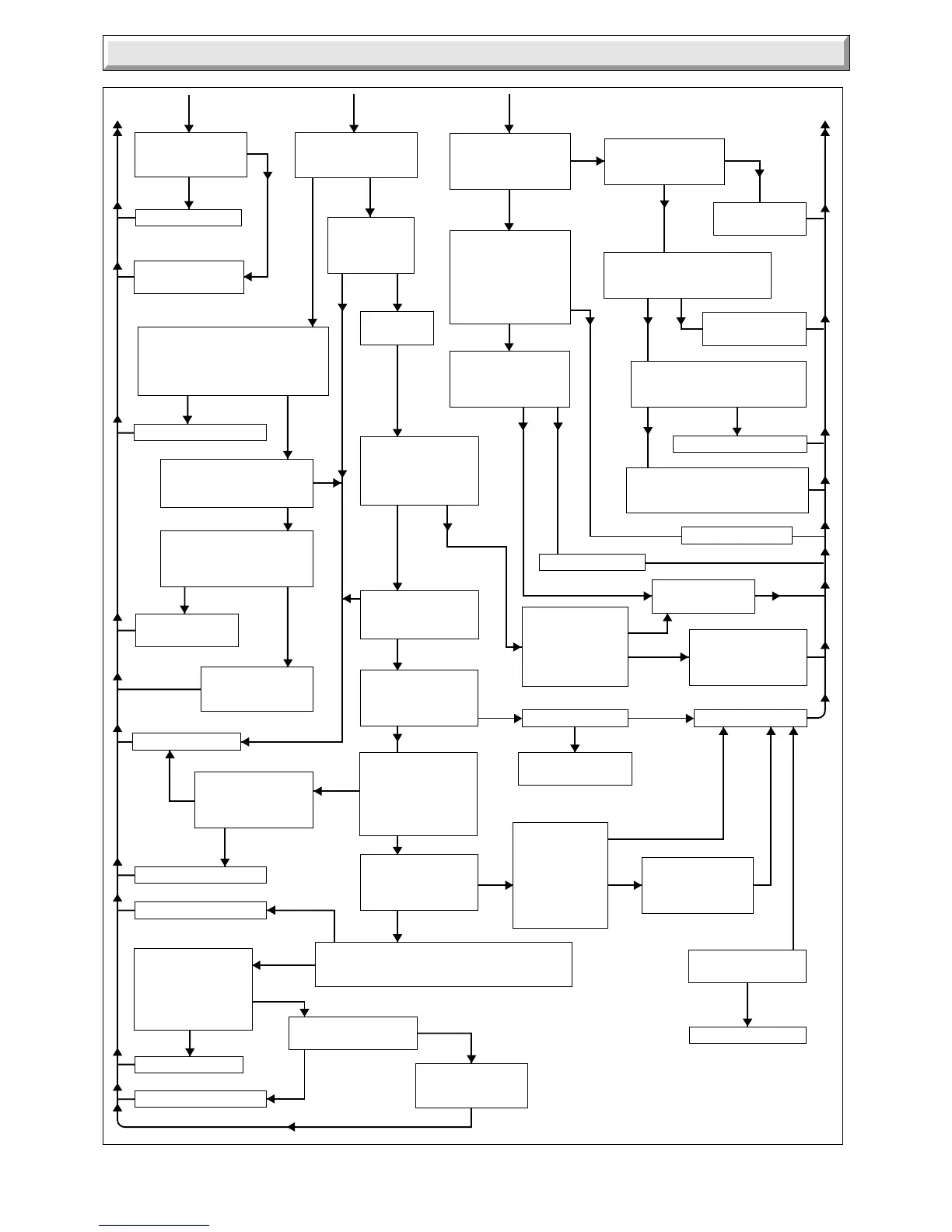

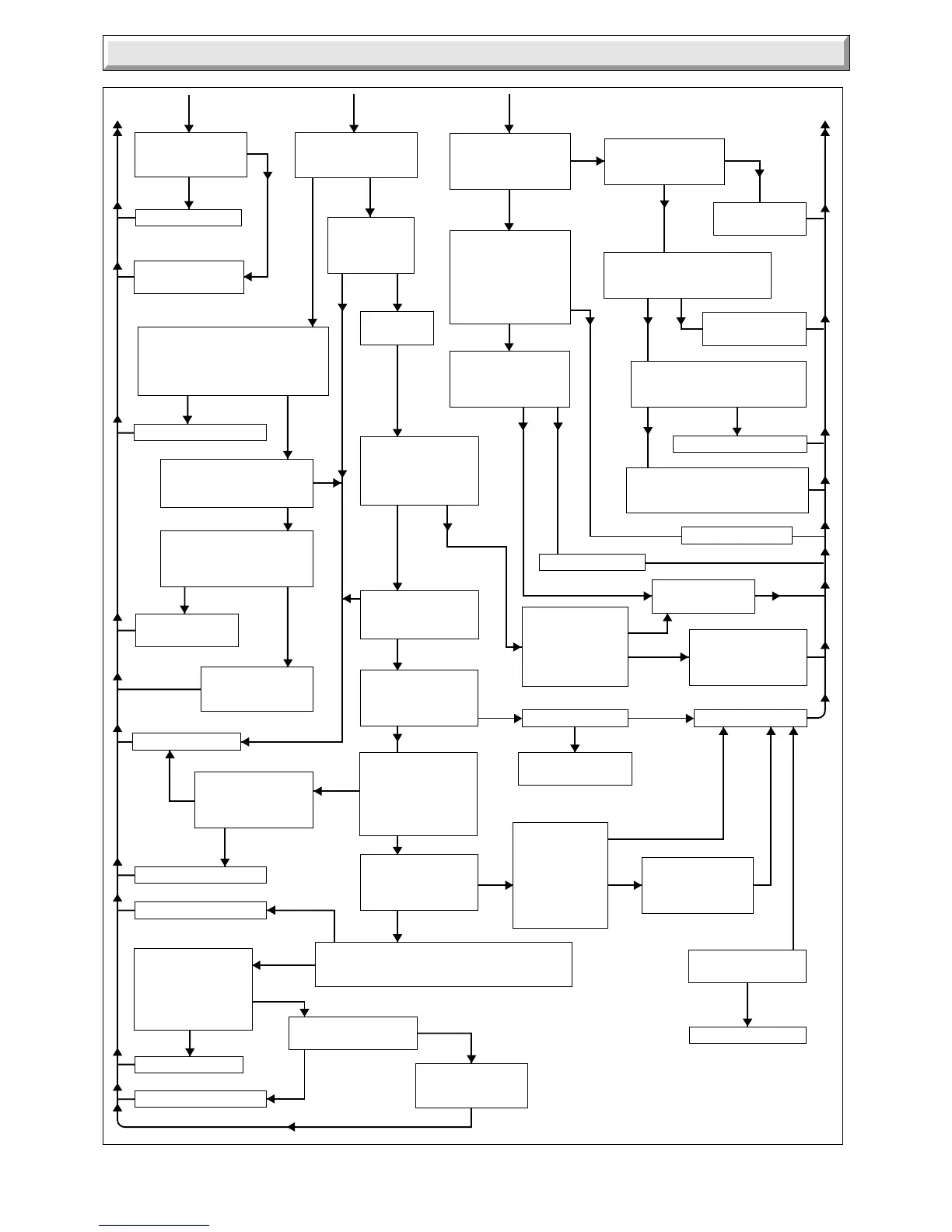

Diagram 3.7 continued

Isolate supply. Is there

continuity between

P.C.B. and modulator?

Reduce D.H.W. flow to

3.7 litres/minute. Does

burner pressure reduce?

Modulation

O.K.

Rectify as necessary.

Faulty modulator,

replace.

Measure D.H.W.

temperature. Is

it between 57

and 63

o

C?

Isolate supply. Remove block 4 from

P.C.B. As boiler cools does resistance

across 'D.H.W. thermistor' pins on

block 4 increase from approx

2.5K Ω to 10KΩ ?

Faulty thermistor, replace.

Faulty modulator, replace.

Faulty modulator,

replace.

Faulty modulator, replace.

Faulty thermistor, replace.

Check continuity from

P.C.B. to modulator.

Rectify if necessary.

Is there continuity across

terminals on modulator?

Faulty P.C.B., replace

Faulty P.C.B., replace.

Isolate supply. Remove

block 1 from P.C.B. Is

resistance across

modulator pins on

block 1 between 120

& 140 Ω?

Isolate supply. Remove block 4 from P.C.B. As boiler

cools does resistance across 'CH thermistor' pins

on block 4 increase from approx 2.5K to 10K Ω?

As heating system

becomes satisfied.

Does burner pressure

reduce?

Does fan and pump

continue to run for

approx. 30 seconds?

Refer to fault finding

Dia. 3.8.

Turn on roomstat or

external CH control.

Does main burner

relight?

With heating system

starting from cold. Is

burner pressure

constant at approx:

S.I.T. 8.8mbar?

Honeywell 9.0mbar?

Set selector switch

to"on".

Turn off D.H.W. flow.

Does main burner

extinguish?

Is there between 4 &

15V DC across

modulator pins on

block 1 on P.C.B.?

Check continuity from

P.C.B. to modulator.

Rectify if necessary.

Is there between 15 and 30V

DC across 'modulator' pins on

block 1 on P.C.B.?

Isolate supply. Remove

connectors from modulator. Is

resistance across modulator

between 120 and 140 Ω?

Rectify as necessary.

Faulty P.C.B., replace.

Faulty transformer, replace.

Faulty P.C.B. , replace. Does pump operate.

Isolate supply.

Disconnect block 4

from P.C.B. Is there

continuity across

'flowswitch' pins on

block 4?

Faulty flowswitch,

replace

Ensure that all external

CH controls are not

calling for heat. Rectify

if necessary.

With D.H.W. demand

of at least 3.7

litres/minute, is there

D.H.W. priority?

Does pump continue to

run for a short period?

Boiler working correctly.

Measure CH flow

temperature. As

heating system

becomes satisfied

is CH flow

temperature

between 78 and

82

o

C

Faulty gas valve,

replace.

Faulty D.H.W. cut

out stat. Replace.

Is there 24V AC across

terminals on main

solenoid on gas valve?

Isolate supply. Is there continuity

across 'D.H.W. cut out stat' pins

on block 1on P.C.B?

Remove block 1 from P.C.B. Is

there continuity across

secondary pins 1&2 on transformer.

Restore supply. Is there

24V AC across 'main

solenoid' pins on block

1 on P.C.B?

Isolate supply.

Disconnect block 4 from

P.C.B. With D.H.W. rate

of at least 3.7 litres/

minute. Is there

continuity across 'flow-

switch' pins on block 4.

Is there continuity

between P.C.B. and

flowswitch in line

connectors ?

Check continuity of cable between

P.C.B., transformer, gas valve &

pressure switch. Rectify if necessary.

YES

NO

NO

YES

YES

Continued

YES

Continued

YES

Continued

YES

NO

NO

YES

YES

NO

NO

YES

YES YES

NO

NOYES

NOYES

YES

NO

NO

NO

NO

NO

NO

YES

YES

NO

NO

YES

NO

NO

YES

YES

YES

YES

YES

YES

NO

NO

NO

YES

YES

YES

NO

NO YES

YES

NO

YES

4457 cont.

With heating system

starting from cold. Is

burner pressure

constant at approx:

S.I.T. 8.8mbar?

Honeywell 9.0mbar?

3 Fault Finding

Loading...

Loading...