52

221469B

4 Replacement of Parts

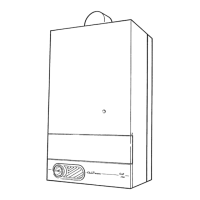

Diagram 4.20

UNION (4)

SEALING

WASHER

AUTOMATIC

AIR VENT

CAP

LOCATION

SLOT

6909

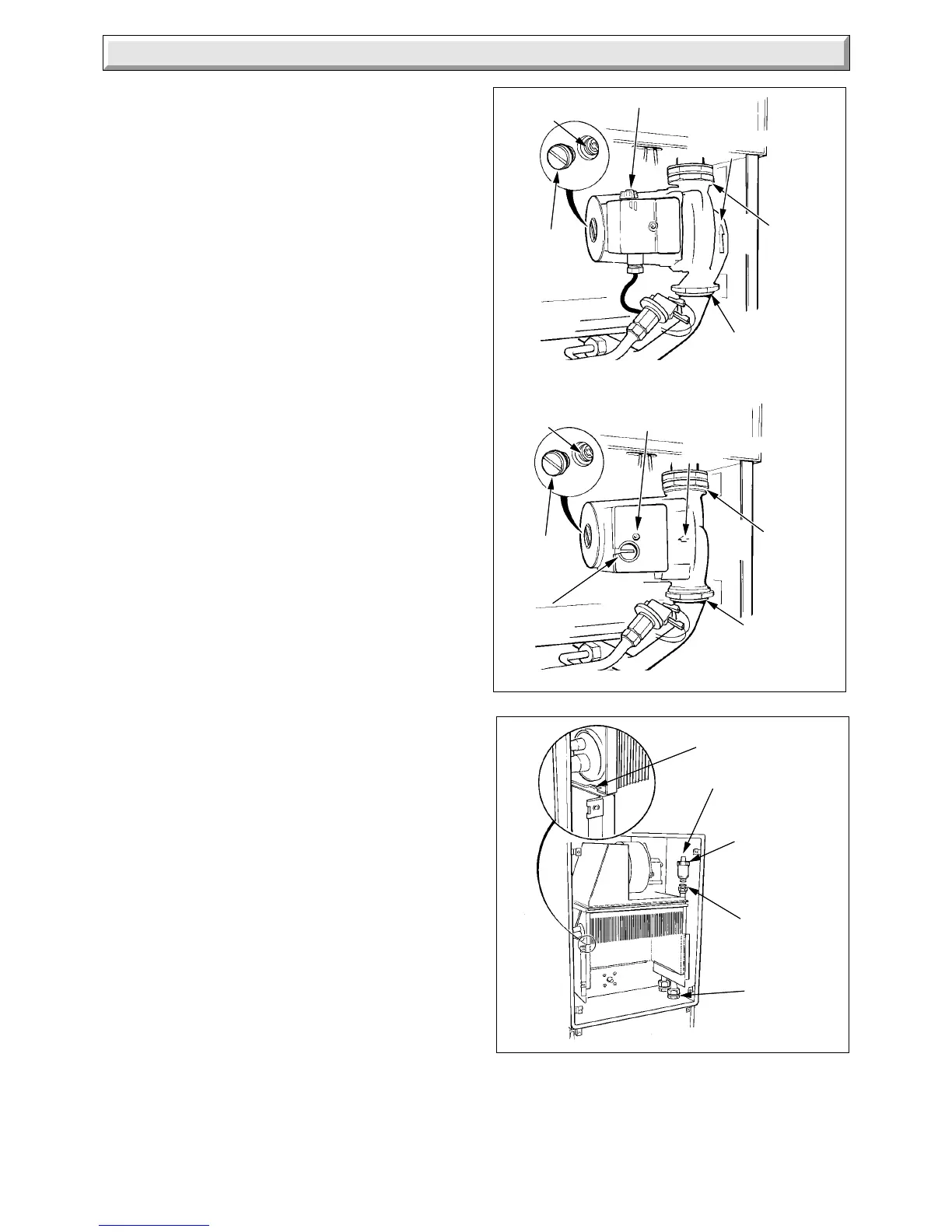

Diagram 4.19

4453 S

LOWER PUMP

UNION

END

SCREW

PUMP

SPINDLE

PUMP

ADJUSTER

UPPER

PUMP

UNION

TERMINAL

COVER SCREW

FLOW DIRECTION

ARROW

END

SCREW

PUMP

SPINDLE

UPPER

PUMP

UNION

PUMP ADJUSTER

4465

LOWER

PUMP

UNION

GRUNDFOS PUMP

WILO PUMP

FLOW DIRECTION

ARROW

4.26 Pump

Before starting refer to Section 1.1.

Isolate the boiler from the electrical supply, refer to Section 1.3.

Remove the outer case, refer to Section 1.4.

Release the water pressure and drain, refer to Section 1.6.

Remove the control housing, refer to Section 4.7 paragraph 7.

Disconnect the electrical connectors at the pressure switch

microswitch. See diagram 4.21.

Remove pressure switch, see diagram 4.21.

Remove the terminal cover from the pump and disconnect the

cables, see diagram 4.19.

Disconnect the pump at the unions, see diagram 4.19.

Discard the sealing washers.

Make sure that the flow direction arrow is pointing upward, on

the pump, when fitting it to the lower pipework, using the new

sealing washers provided.

Refit pressure switch. Use jointing compound to ensure a sound

joint.

Set the flow adjuster on the pump to maximum setting. The flow

rate should controlled by means of a valve in the heating

system.

Make up water loss and pressurise the system, refer to

Commissioning in the Installation Instructions.

Note: Should the pump fail to work, see diagram 3.7. If all is in

order but the pump still does not work, remove the screw, see

diagram 4.19 then turn the pump spindle to release any temporary

seizure. DO NOT HIT THE SPINDLE.

4.27 Automatic Air Vent

Before starting refer to Section 1.1.

Isolate the boiler from the electrical supply, refer to Section 1.3.

Remove the outer case and the cover of the inner case, refer to

Sections 1.4 and 1.5.

Release the water pressure and drain, refer to Section 1.6.

Remove the automatic air vent, see diagram 4.20.

Discard the sealing washer and use the new one supplied,

when fitting.

Slacken the small cap on the air vent. This MUST NOT be

retightened.

Make up water loss and pressurise the system, refer to

Commissioning in the Installation Instructions.

4.28 Pressure Switch

Before starting refer to Section 1.1

Isolate the boiler from the electrical supply, refer to Section 1.3.

Remove the outer case, refer to Section 1.4.

Release the water pressure and drain, refer to Section 1.6.

Remove the control housing, refer to Section 4.7 paragraph 7.

Disconnect the electrical connectors at the microswitch, see

diagram 4.21.

Remove pressure switch see diagram 4.21.

On assembly use jointing compound to ensure a sound joint.

Make up water loss and pressurise the system, refer to

Commissioning in the Installation Instructions.

Loading...

Loading...