English • Owner´s manual

32

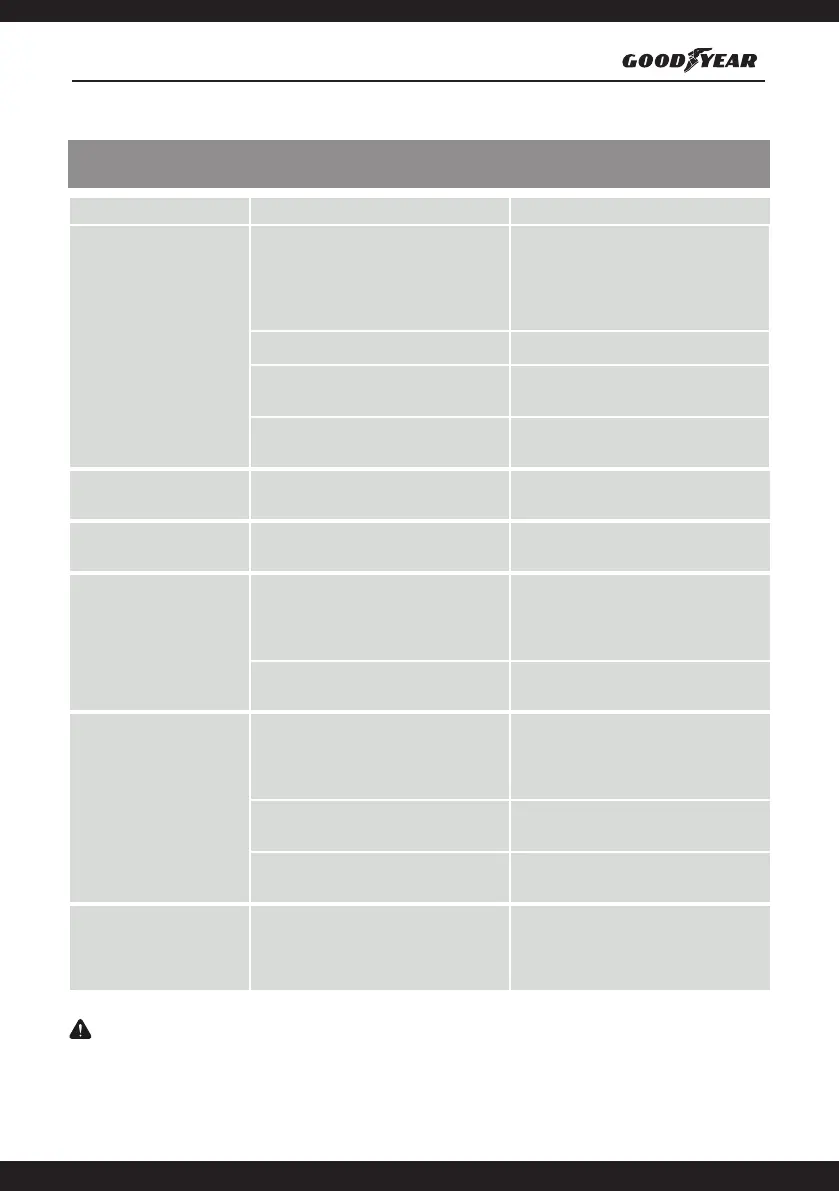

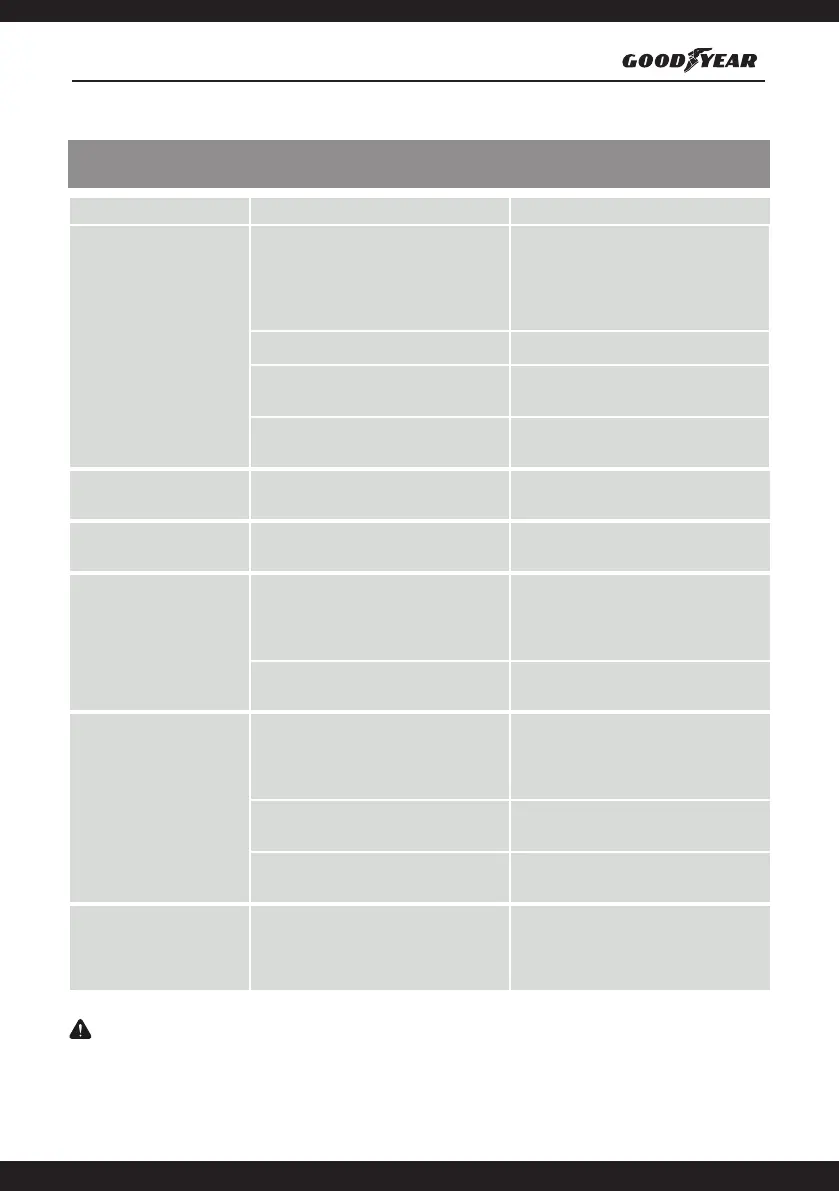

8. TROUBLESHOOTING

Problem Possible cause Solution

Engine does not start.

No or too low voltage.

Make sure that the plug is inserted into

the socket.

Check the fuse and replace it if

necessary.

Check the mains voltage.

Outdoor temperature too low. Ensure +5 °C ambient temperature.

Device is not switched on.

Press the on/o switch to position “I”, to

switch on the compressor.

Extension cable is too long or too thin.

Replace the extension cable (min. 1.5

mm², max. 5 m long).

Unusual noises Pneumatic connectors are loose.

Check all connecting parts and tighten

them carefully if necessary.

Strong vibrations Pneumatic connectors are loose.

Servicing and maintaining the

compressor.

Compressor switches on

frequently.

Compressor is overloaded.

Observe the manufacturer’s

instructions for your tool or equipment,

especially with regard to the amount of

compressed air required.

Too much condensation in the

pressure vessel

Empty the pressure vessel regularly.

Compressor runs without

interruption / compressor

does not reach cut-o

pressure.

LAir consumption for connected

pneumatic tools and devices is too

high.

Comply with the manufacturer’s

instructions for your pneumatic tool,

especially with regard to the amount of

compressed air required.

Quick couplings leaking.

Check quick coupling , replace if

necessary.

Pneumatic connectors leaking.

Check pneumatic hose and tools,

replace if necessary.

Air leak from pressure

switch valve with

compressor o

VCheck the valve that, due to wear or

dirt on the gasket, does not perform its

function correctly.

Unscrew check valve hex head, clean

valve seat and rubber gasket (replace

if worn). Reassemble and carefully

tighten (Fig 15 y 16).

ATTENTION: Do not make any modications to the machine that may damage its operation. Any

alterations or modications made will invalidate the product warranty.

If your device continues to give errors or presents any other type of problem, please contact our

technical service so that our team can advise you and solve the problem.

Loading...

Loading...