INSTALLING THE RACK

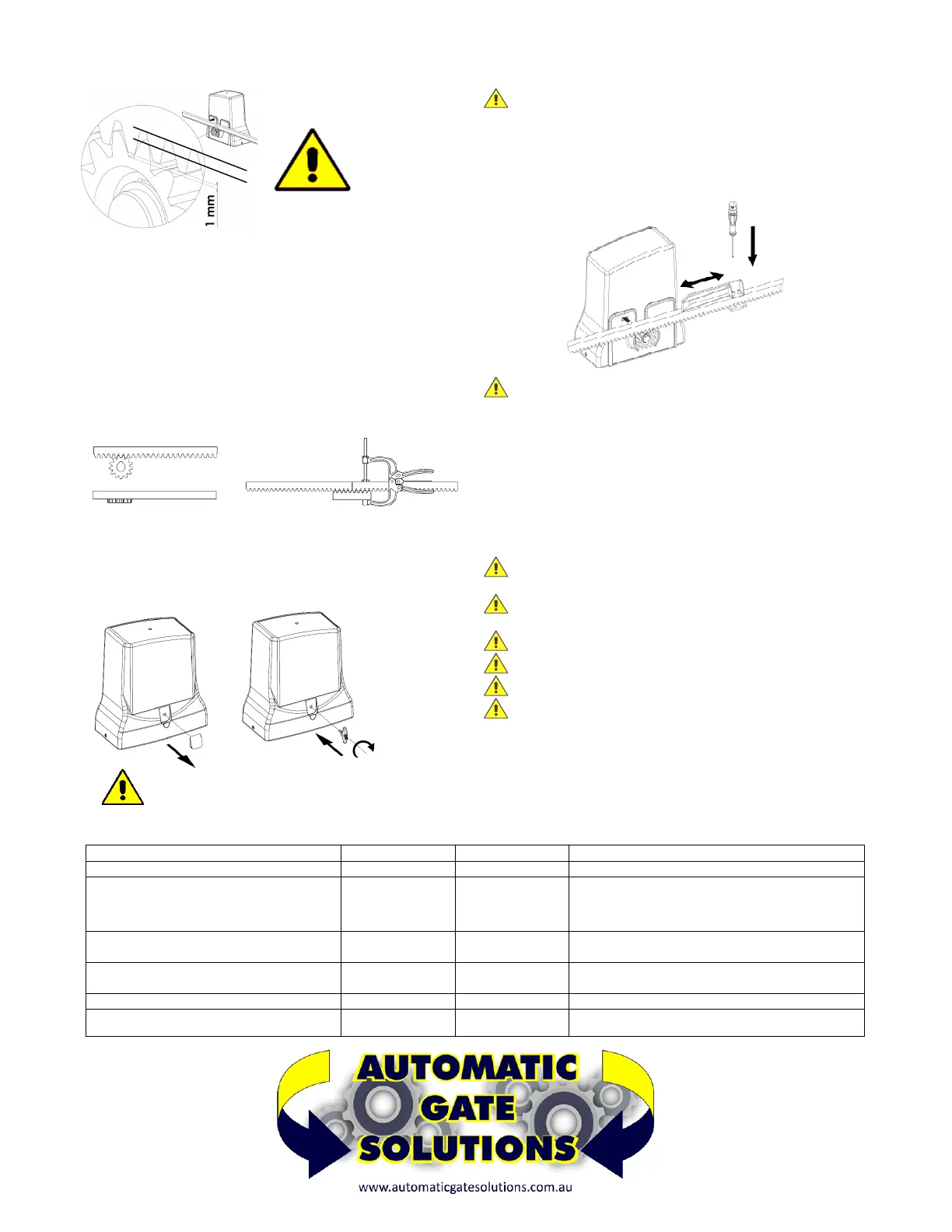

I

f the rack is already installed, check that there is a space of

approximately 1mm between the drive wheel and the rack FIG.5,

if the rack is not installed, proceed as follows:

–

Take the first piece of rack and position it on the motor sprocket

making sure that at the end of the installation there is always 1mm of

space (if necessary use temporary shims under the motor). Slide it to

the point indicated in FIG. 5

– Weld or screw the first pin or spacer to the gate (depending on the

type of rack).

– Apply all the other elements of the rack so that they are perfectly

joined and aligned with the first one. Use pliers and a piece of rack for

perfect alignment of one element with the other. See FIG. 6

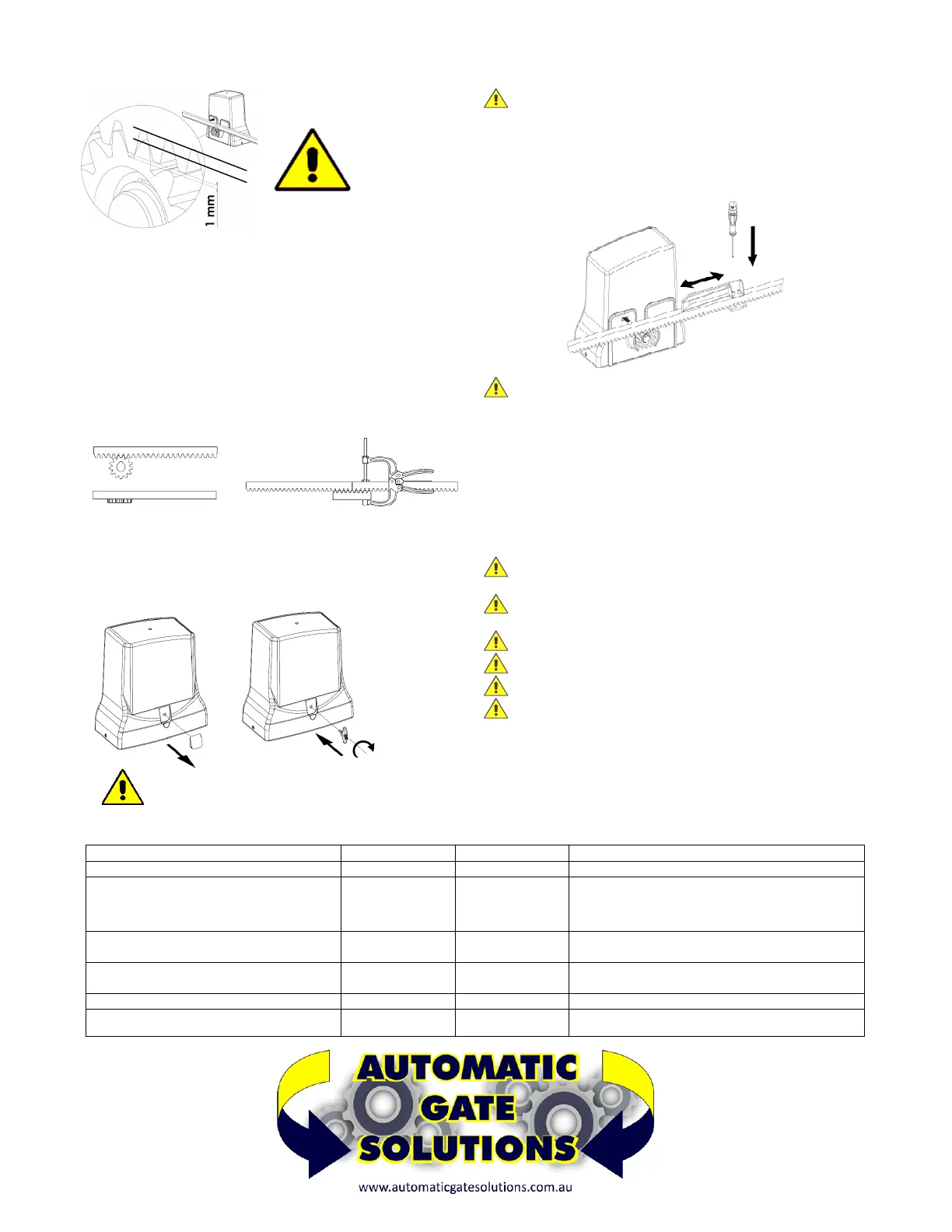

EMERGENCY RELEASE

To

unlock the motor proceed as follows:

– remove the cap D

– Insert the supplied key E and turn CLOCKWISE for 4 turns FIG.7

– To overturn the motor turn ANTICLOCKWISE for 4 turns

FI

NAL OPERATIONS

Once the rack and motor have been fixed, release the motor see

FIG.8, and move the gate to check that it slides freely and effortlessly.

ATTENTION v

érifier qu'il ne "repose" pas sur la roue motrice du

moteur. Dans ce cas, réglez la crémaillère pour laisser environ 1 mm

d'espace entre le pignon du moteur et la crémaillère

– Install the limit switch cams on the rack FIG. 8 without fixing them in

a definitive way, in order to be able to adjust them in the optimal

position when programming the control unit.

CAUTION T

he limit switch cams are used to operate the limit

switches of the motor which, by means of the control unit, interrupt the

movement of the gate during opening and closing. They must be

positioned at the ends of the rack taking into account any inertia and

the delay in stopping the gate with respect to the operation of the limit

switches.

– Proceed with the electrical connections, program the control unit,

carry out the final test and reinstall the cover cards.

SCHEDULED MAINTENANCE WARNINGS

B

efore any maintenance operation, disconnect the power using

the main switch

T

he equipment must be maintained in such a way as to maintain

the conditions that guarantee safety and correct operation

A

lways use original spare parts

D

o not carry out any interventions that modify the machine

The modified machine needs a new CE mark

The adjustment of the function of the automation must be carried

o

ut by specialized personnel, in compliance with the relevant

regulations. During these operations the presence of two operators is

expected

SCHEDULED MAINTENANCE - OPERATIONS

DESCRIPTION FREQUENCY ENTRUSTED OPERATION

Photocells cleaning

Monthly Operator Clean with damp cloth

Control of the gate supports of the fall arrest

devices, the limit stops, the rack, the sliding

guide and the sliding of the gate

According to

necessity

Operator Check the integrity of all items, state of welds and

corrosion. Unhook the motor and check the friction

points of the gate and the distance between the

pinion and rack (1.0mm).

Control of the sensitivity of the electronic

clutch (torque regulation) of the control unit

Semiannual Technician Check the torque adjustment as indicated in the EN

12453 - EN 12445 standard

Control of the IP protection Semiannual Technician Check that there are no traces of moisture or water

inside the electrical enclosures

Monitoring current dispersion Annual

Technician Verify that the dispersion of current is less than 7.5 A

Control of signals Semiannual Operator Verify that the safety warning signage is complete

and intact

FIG. 5

FIG. 6

FIG.8

D

4

TURNS

CAUTION DO NOT RE-LOCK THE MOTOR WHILE

I

T‘S RUNNING

FIG.7

Loading...

Loading...