Repair

14 308655K

9. Align the holes in the valve nuts (21*) and the slots

on the top of the inlet valve poppets (32*), and drop

the lock wires (22*) through the holes in the valve

nuts and into the slots in the inlet valve poppets.

Pull the lock wires down tightly, and bend the ends

with pliers so that they cannot be pulled back out of

the holes.

10. Grease and install the new o-rings (19*, 20*) on the

piston assembly (27) and in the groove in the air

motor base (28).

11. Clamp the air motor base (28) in a vise horizontally

by closing the vise jaws on the flange.

12. Grease and reinstall the u-cup seal (10†), thread

and throat bearing (36) into the air motor base (28),

and torque the throat bearing to 30 to 40 ft.-lbs

(40.7 to 54.2 N•m) using a 2 in. socket.

13. Slide the piston rod (29) down through the packing,

and lower the piston assembly (27) into the air

motor base (28).

14. Carefully lower the cylinder (30) straight down onto

the piston assembly (27). Tighten the eight screws

(3) holding the cylinder to the base (28).

15. Grip the trip rod (31) with padded pliers, screw the

lift ring (24) onto the tip rod, push the lift ring down,

and screw it into the top of the cylinder.

16. Install the u-cup packing (107†) with the lips facing

up, and place the piston washer (113) on the

piston/valve sear (109). Make sure that the lips of

the u-cup packing face up (F

IG. 3)

17. Place the piston ball (103) in the piston rod (29).

18. Clean the threads of the piston/valve seat. Apply

thread locking compound to the threads (109), and

thread the assembly from step 16 onto the piston

rod (29).

19. Clamp the flats of the piston/valve seat (109) in a

vise, and torque the piston rod (29) to the piston

valve seat to 40 to 60 ft.-lbs (54 to 81 N•m).

20. Clamp the air motor base (28) in a vise horizontally

by closing the vise jaws on the flange.

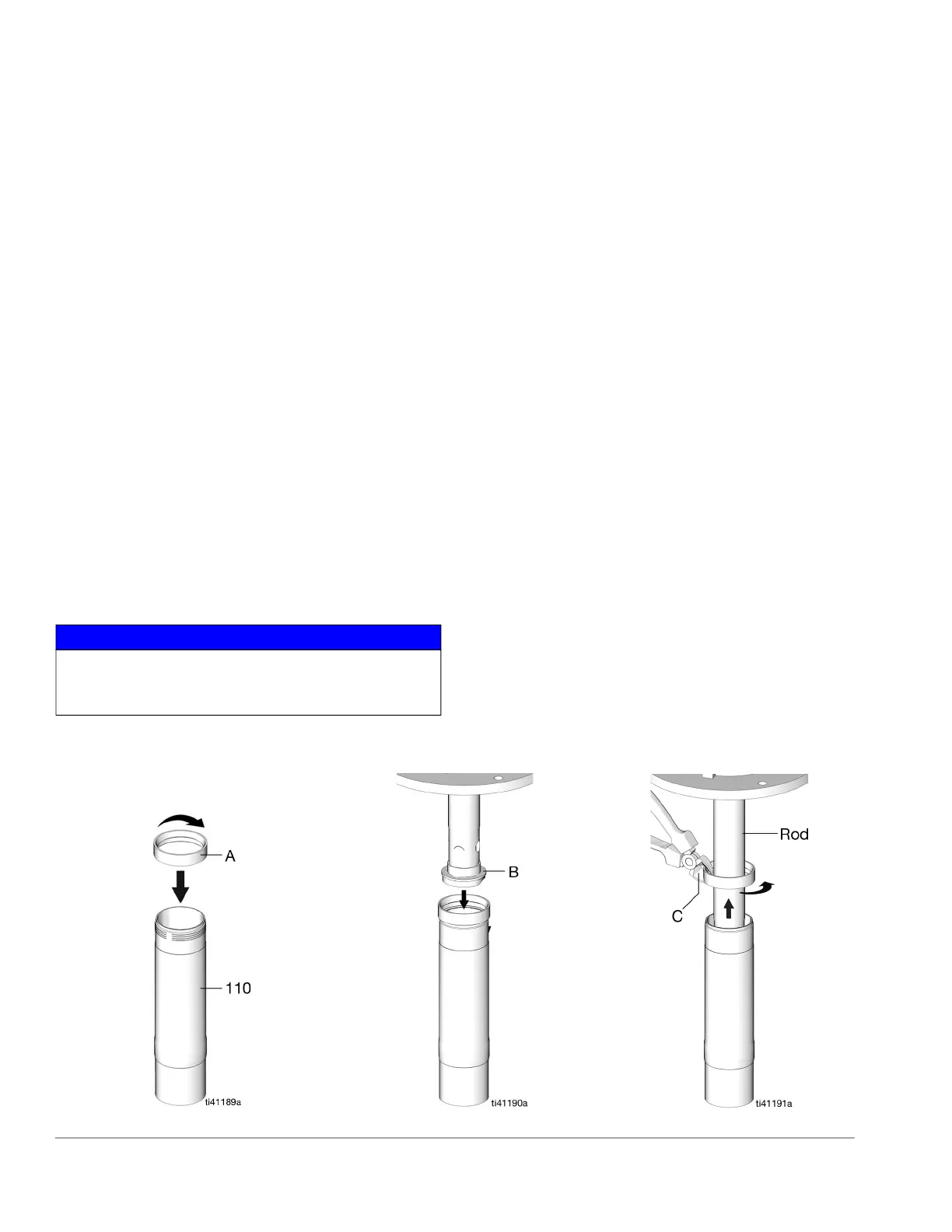

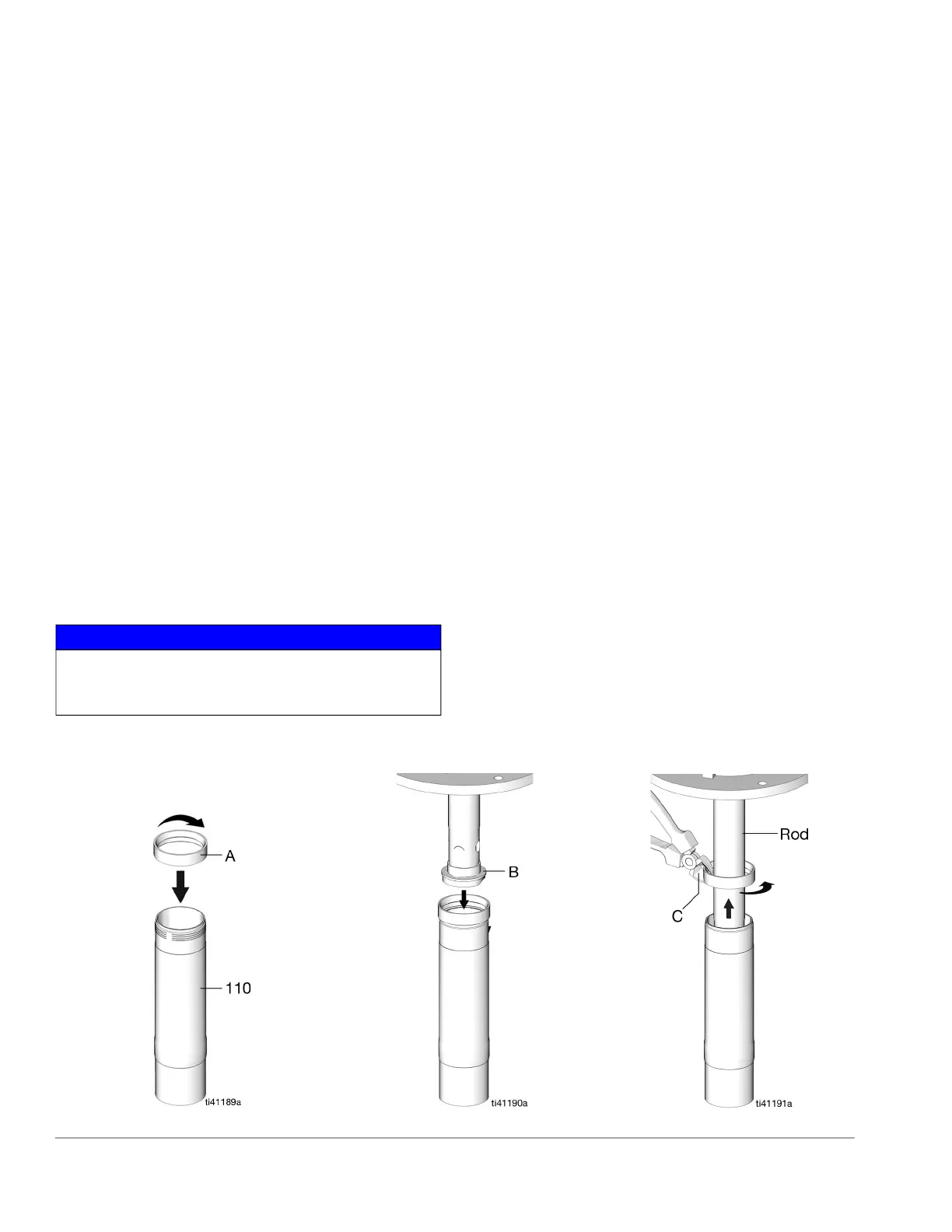

21. Thread the piston assembly tool (A) (included in

Repair Kit 238751) onto the threads of the

displacement pump cylinder (110). See F

IG. 5.

22. Insert the piston assembly (B) into the displacement

pump cylinder.

23. Remove the piston assembly tool from the

displacement pump cylinder.

NOTICE

To avoid damaging the cylinder wall, lower the

cylinder straight down onto the piston. Never tilt the

cylinder as it is being lowered.

FIG. 5

Loading...

Loading...