11307-050

Service

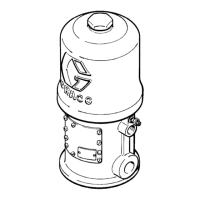

Stroke Adjuster Repair (Fig 5)

CAUTION

If

you do not remove the trip rod (33), record the

indicator reading BEFORE removing the adjuster

assembly (3) so that you can set it at the same

number when reinstalling it. This will keep the adjust

-

er setting in agreement with the stroke setting and

prevent possible damage to the air motor

.

WARNING

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 7.

1.

Relieve the Pressure

2.

Loosen

the housing collar setscrew (9). Holding

the

adjuster

assembly (3), screw the

collar (24) out of the

detent housing (82). Now lift the adjuster assembly

up.

3.

Remove

the cover (15). Remove the setscrew (6)

on

the

side which holds the gear adjusting shaft (21).

4.

Pull out the shaft (21) and adjusting knob (20), and

then remove the gear (14).

5.

Remove

the end plate (18). Remove

the setscrew (6)

from

the gear (14). Pull out the shaft (22) and indica

-

tor

(12), and then remove the gear (14).

CAUTION

Be careful not to drop or damage the indicator (12),

which can be easily damaged.

6.

If you need to replace the indicator (12), loosen the

two

setscrews (1

1) in

the shaft (22) and pull the indi

-

cator

of

f of the shaft. When installing a new indicator

,

tighten

the setscrews (1

1) firmly into the shaft.

7.

Remove the remaining gear (26) from the retainer

(23).

8.

Clean the gears and shafts thoroughly. Inspect all

parts

and replace any that are worn or damaged.

9.

When reassembling the adjuster, align the holes in

the shafts with the setscrews, and tighten the

setscrews

snugly

.

10. If

necessary

, add more grease to the stroke

adjuster

housing

(16) until it just covers the

center gear (26).

Do

not lubricate the indicator (12).

01818

Fig 5

10131920

21

24

78

18 25 12

2211

5

4

15

6

14

26

23

27

17

REF

NO. 3

STROKE ADJUSTER ASSEMBL

Y

INCLUDES ITEMS 4–27

9

16

Loading...

Loading...