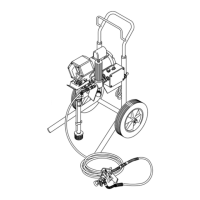

Before each use, squirt one drop of oil onto the lower

pivot point (J) of the pump (33). See Fig 5.

For very short shutoff periods, relieve pressure, leave

the suction tube in the paint and clean the front of the

spray tip.

Check the packing nut/wet cup (38) before each use

and periodically when in use. Follow the Pressure Relief

Procedure Warning before checking or tightening. The

packing nut should only be tight enough to stop

leakage. Do not over tighten. Overtightening may cause

binding and excessive wear on the packings.

Clean the outlet filter often and whenever the sprayer is

stored. On the last workday of the week, flush all the

paint out of the sprayer. See “Flushing Guidelines,’ on

page 9. If you are using a paint that will dry overnight,

flush the sprayer daily at shutdow’h.

Always push the suction tube onto the clip (13) on the

side of the frame (6) and wrap the hose around the

sprayer when storing it, even if only overnight, to help

protect the hose from damage.

Do not store the sprayer with water in it. Even for over-

night storage, you should fill the sprayer with mineral

spirits. This prevents rust and greatly extends the life of

the sprayer.

CAUTION

Do not let water freeze in the pressure control or

pump in cold weather. Freezing could cause a

change in the pressure control calibration or strip-

ping of gears, resulting in loss of pressure or

stallina.

Fig 5

Once a month, lubricate the needle bearing (36) in the

displacement rod (34); use a grease gun to apply the

grease to the grease fitting (35). See Fig 5.

Periodically, or if the motor overheats, unplug the

power supply cord, follow the Pressure Relief Pro-

cedure Warning on page 10, and clean all paint and dirt

off the motor. Change the gearcase oil at least once a

year, using Grace Gear Oil no. 206-230. The gearcase

holds 3 pints (1.4 liters). Don’t use hypoid grease.

307460 11

Loading...

Loading...