Do you have a question about the Graco EM 480 Hydra-Spray and is the answer not in the manual?

Details risks associated with high-pressure fluid injection and eye contact.

Safe practices for operating the sprayer, including gun handling and tip guard use.

Ensures safety latch, diffuser, and tip guard are functional before use.

Immediate emergency care instructions for fluid injection into skin.

Step-by-step guide to safely relieve pressure before maintenance or shutdown.

Avoids damage and injury from over-pressurizing, modifications, or incompatible materials.

Instructions for grounding sprayer, hoses, and gun to prevent sparks.

Avoids pinching or amputation from moving components during operation.

Ensures proper oil level in the gearcase for lubrication.

Connects spray hose and whip end hose to the gun and filter.

Fills the packing nut/wet cup with TSL for pump protection.

Checks electrical requirements and proper grounding for the power cord.

Connects the power cord to a grounded outlet away from the spray area.

Sets pressure control knob to minimum for pump protection.

Importance of proper flushing for maintenance and pump longevity.

Guidelines on when to flush the sprayer based on paint type and storage.

Detailed procedure for flushing the sprayer with solvents or water.

Instructions for preparing paint, including stirring and straining.

Steps to prime the sprayer, remove air, and prepare for hose priming.

Installing the spray tip and guard, and tightening the retaining nut.

Adjusting pressure control for desired spray pattern and width.

Procedures for cleaning spray tips and clearing clogs safely.

Procedure for safely shutting down and caring for the sprayer.

Instructions for removing and installing bearings in the displacement rod and intake valve.

Steps to remove and install the sprayer motor assembly.

Procedure for replacing the motor starting capacitor.

Procedure for removing and replacing the displacement pump.

Steps for removing and replacing the intake valve assembly.

Replacing throat packings, displacement rod, and piston components.

Procedure for removing and replacing the pressure control assembly.

Steps for removing and replacing the circuit board.

Troubleshooting causes and solutions for motor failure to start.

Diagnosing and resolving issues when the motor stops during operation.

Identifying causes for low output when the motor is running.

Crucial safety warning for all service and maintenance operations.

Diagnosing issues when the motor runs but produces no output.

Troubleshooting causes for paint leaking into the wet-cup.

Addressing causes of pulsing or surging spray from the gun.

Resolving issues of insufficient paint pressure.

Identifying and fixing causes of an irregular spray pattern.

Troubleshooting causes for spitting or intermittent spray.

Ensuring proper grounding to prevent static discharge from the gun.

Step-by-step guide to calibrate the sprayer's pressure control for optimal performance.

List of required tools and materials for pressure control calibration.

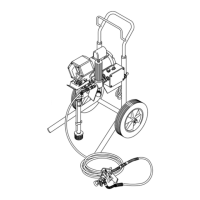

Visual representation of the sprayer components with reference numbers.

Diagram of the fluid filter and pressure control assembly.

Detailed list of sprayer parts with part numbers and descriptions.

List of parts for the pressure control switch assembly.

List of additional sprayer parts and accessories.

Detailed parts breakdown for the displacement pump assembly.

List of parts included in the displacement pump repair kit.

Key technical specifications for the EM 480 sprayer.

Details Graco's warranty coverage for equipment and parts.

Specifies conditions not covered by warranty and liability limitations.

Addresses warranties for non-Graco manufactured components.

| Brand | Graco |

|---|---|

| Model | EM 480 Hydra-Spray |

| Category | Paint Sprayer |

| Language | English |