8ą306-934

TROUBLESHOOTING

CHART

WARNING

Pressure

Relief Procedure

To reduce the risk of serious bodily injury, including

fluid

injection, splashing in the eyes or on the skin,

or

injury

from moving parts, always relieve all air and fluid

pressure in the system before checking or repairing

the

ram or any other part of the system

and when shut

-

ting

down the system.

1.

Shut of

f the air to the pump and ram.

2. Open the bleed–type master air valve to relieve

trapped

air.

3.

Shut of

f the ram director valve.

4. T

rigger the gun/dispensing valve to relieve

fluid pressure.

5.

Open all fluid drain valves in the system.

6. Leave

the drain valves open until you are ready to

spray/dispense

again.

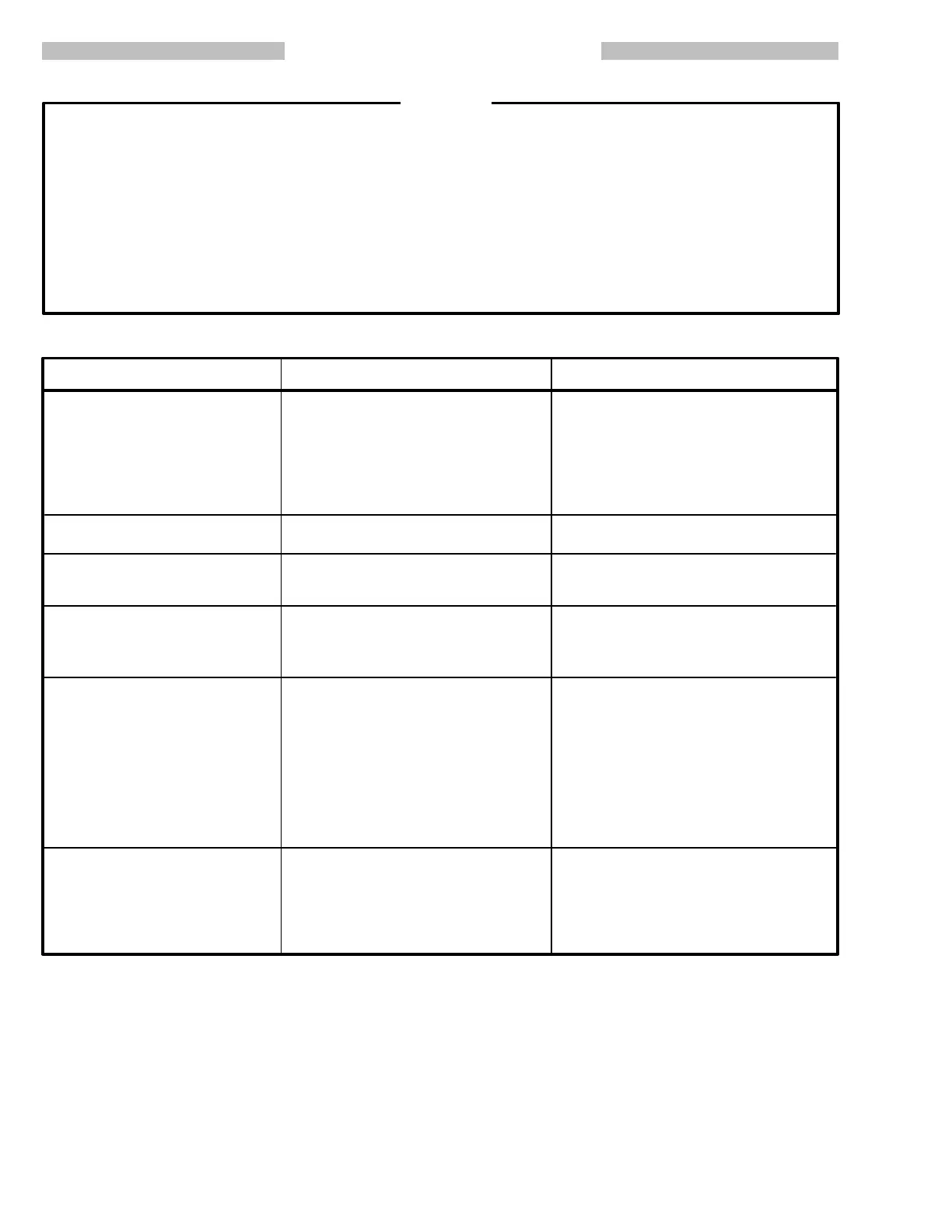

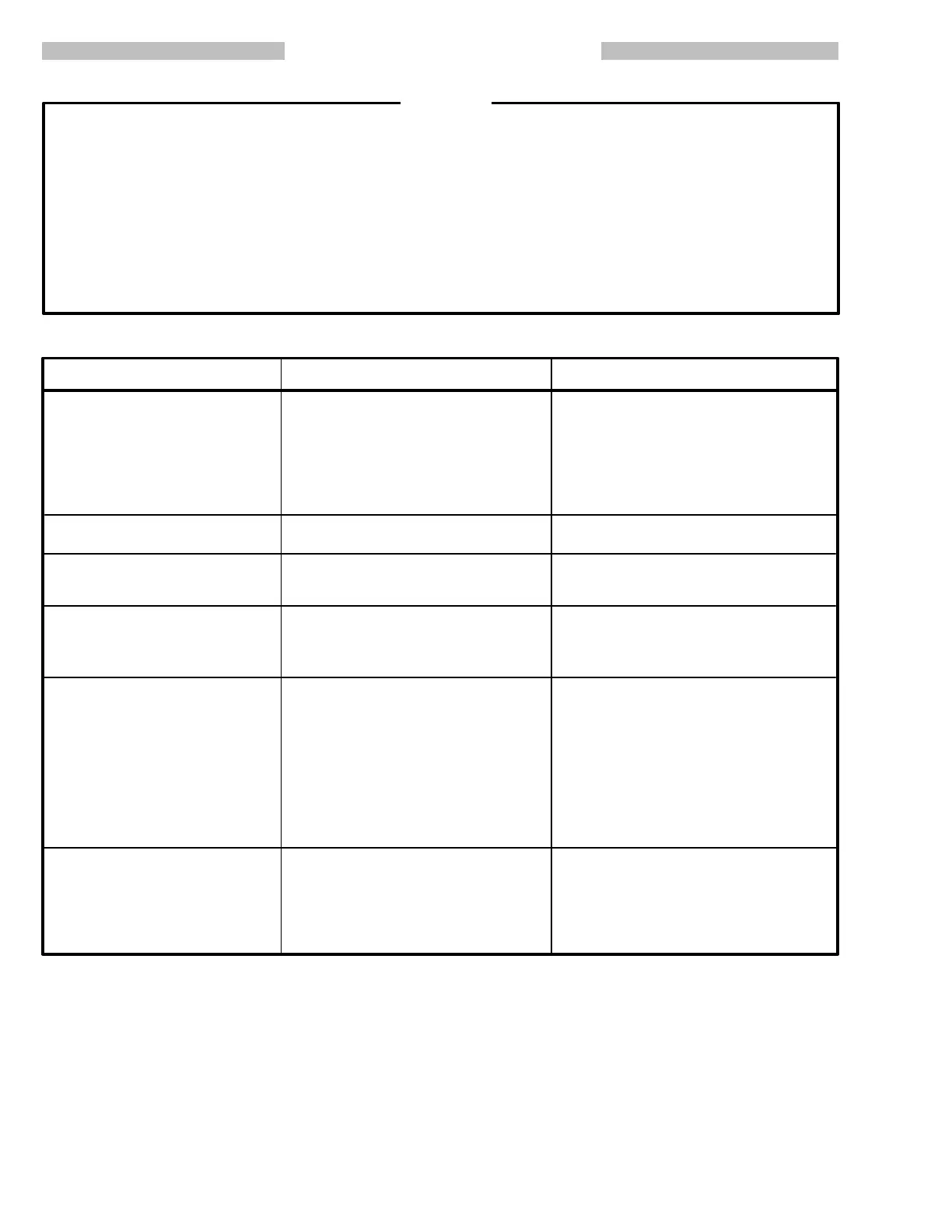

PROBLEM CAUSE SOLUTION

Ram won’t raise or lower

Closed air valve or clogged air line

Open, clear

Not enough air pressure

Increase

W

orn or damaged piston

Replace

Director valve closed or clogged

Open, clear

Ram raises or lowers too fast Air pressure too high

Decrease

Air leaks around cylinder

Loose packing nut or worn packings

T

ighten, replace

packing nuts (46)

Fluid squeezes past

Air pressure too high

Decrease

ram plate wipers

W

orn or damaged wipers

Replace

Pump won’t prime properly or

Closed air valve or clogged air line

Open, clear

pumps air

Not enough air pressure

Increase

W

orn or damaged piston

Replace

Director valve closed or clogged

Open, clear

Air director valve dirty

, worn

Clean, service

or damaged

Air director valve won’t hold

Closed air valve or clogged air line

Open, clear

drum down or push plate up

Not enough air pressure

Increase

V

alve passage clogged

Clean

Loading...

Loading...